Onshape – A look at what’s been added, changed and enhanced in this cloud-based design and engineering system in the intervening time

Unless you’ve been sat on a rock and off the grid for the last two years, you’ll have heard about Onshape. Founded by the core team behind SolidWorks, Onshape launched to much fanfare last year with it’s 100% cloud-based design application.

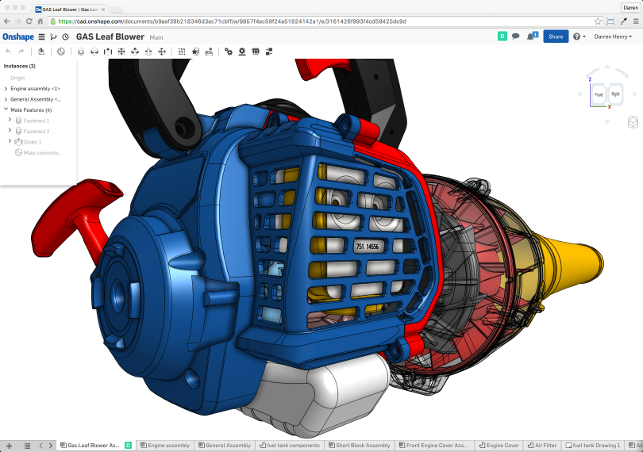

Onshape’s UI is evolving from its initial releases, getting more cohesive with each update and gaining more flexibility where needed

This means no installation and no software locally held on your workstation. You simply open up a browser, log in and away you go.

Onshape consistently updates its functionality every three weeks, so we’ll get up to speed with where things are right now. After all, unless you’re tracking updates, chances are that you’ll have missed some of the big items since we last looked at it at the start of the year.

Onshape – core tools and functionality

Right at the outset, let’s discuss one of the biggest benefits of a purely cloud-based infrastructure for complex software.

The benefit is that there’s no rolling out of updates, no adoption of annual 18 month release cycles. You log in and you’re on the latest version — as is everyone else using it. That simple fact alone takes away a lot of the headaches associated with software in the professional design and engineering space.

While that’s a huge benefit for an organisation (in terms of administration reduction), it’s also something of a curse.

The issue is that if you’re using another set of tools (or indeed, using Onshape for production), the time you have available to learn about new features and functions every three weeks is, I would imagine, limited. That said, Onshape do a good job of providing learning resources to get you up to speed — assuming that you take the time to watch them. Anyway, on with the updates.

When we last looked at Onshape, the core set of tools were developing nicely.

Those tools focus on core solid and surface modelling with the set of operations you’d expect — extrude, revolve, loft, sweep etc. These are now pretty much all in place. But what has possibly been the biggest update in recent months is to expand how those features interact.

A perfect example is mirroring. When we last published a review of Onshape, mirror only worked with bodies. If you wanted to replicate features across a part’s centre line, you needed to model them as a separate body, create the mirror, then boolean them all back together.

This has been fixed for a large proportion of the features in the system (such as patterns, arrays and many others). What Onshape has done is extend the flexibility of these features.

To continue our mirror example, when opening the operation, you now have a drop down that gives you the option to mirror bodies (referred to as parts), features or indeed, individual faces.

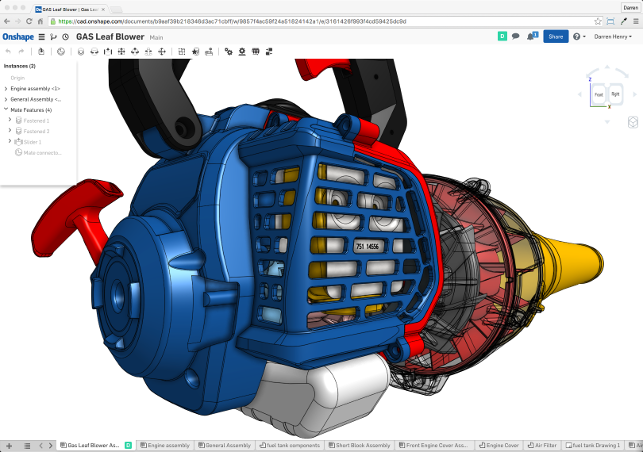

Elsewhere there have been updates to many of the core modelling tools. Lofts, for example, now come with a lot more options than before.

Each profile can be controlled in terms of tangency and curvature connection to adjacent faces, whether you want that tangency normal to the profile or from faces, and much more. Essentially, it’s about more control to let you get the form you want.

Another quick update to note in this section is that the end conditions for many operations have been expanded.

You’ve now got a good set, which includes “up to vertex” as well as the usual to next face, to distance and symmetric.

Of course, as well as updates to existing operations, there are some brand spanking new tools.

One that will be useful for many, particularly those working on injection moulded components, is the new Rib tool. This follows the conventions you’d expect — create a sketch within the shell of the part, sketch out the central lines for the ribs, then have the system build them out to your requirements.

At present, there’s no draft option in any of Onshape’s operations, but these can be added manually later (I’d expect this issue with ‘in operation’ draft to be fixed at some point soon).

Another new feature added in the last few months is the hole tool. It seems strange, but this is something that’s key for many. The ability to accurately define a hole or set of holes based on standard thread forms and tolerances (for pass through holes) is essential. It makes life so much easier if that information is available at source, rather than having to manually document each on a drawing.

Onshape – parts & assemblies

At its early releases, I struggled to explain (to myself, mostly) how Onshape’s part and assembly studios work.

Much of that confusion centred on the fact that, like many of our readers, I’ve been used to working with a file-based system for decades now.

That said, Onshape’s environment meant that the differentiation between creating multi-body part models and then using the assembly environment to fit them together seemed like a retrograde step in comparison with traditional tools’ ability to allow in-context edits of part geometry within an assembly.

While there’s still some work to do, there’s been a few updates that make it less of any issue. One example is the addition of the ‘Derive part’ option within Part Studio.

This allows you to bring geometry in from another part studio and use it in the geometry creation process. The image below shows a set of geometry from another part file, derived into the part studio and used as the basis for further work.

At present, that doesn’t mean that the originating part updates (and it probably shouldn’t by default), but work is being done to make this more consistent with expectations, including the ability to split ‘bodies’ out from a single part studio into their own tab, which will make things much easier in terms of data reuse.

These tools also give rise to an interesting workflow when working across projects, across suppliers, even.

If your supplier also uses Onshape, it’s possible to integrate their products into your own (using an externally referenced and shared file). The version that you’ve inserted references that specific version.

If the supplier updates that product and releases a new version, you can choose whether to stick with the older model or to adopt the newer version (and have any references update where needed). Then consider this in the opposite direction.

That’s an interesting environment in which to conduct complex (in terms of supplier/customer data sharing) design.

A good example of how features are being expanded and extended in terms of options. The loft operation now has a lot more control over end conditions

Onshape – working with mesh data

If you’d had thought that five years ago the ability to work with a mesh file would be high on most CAD vendor’s priorities, you’d have been wrong.

But, of course, since then the mesh formats (STL, OBJ etc.) have become perhaps one of the most widely circulated forms of geometry — you can thank the 3D print hype cycle for that.

The latest update to Onshape brings online the ability to read in mesh data (using the STL format for now) and integrate it into the modelling workflow.

At present, the tools are rudimentary (allowing you to import, position and reference), but this should grow. I’d hope to see some fixing tools as well as tools that allow you to take, if not reference surfaces, certainly reference sections from it some time soon.

Extendiing Onshape + apps

This is perhaps one of the biggest additions outside of the core Onshape toolset.

As with most systems, Onshape is building a community of developers that are extending and enhancing the tools within the core functionality. SolidWorks has its partner program, Inventor has the same, as does Creo, NX etc.

Of course, due to Onshape’s nature, this isn’t quite as clear cut as downloading an application that either runs inside or alongside the system.

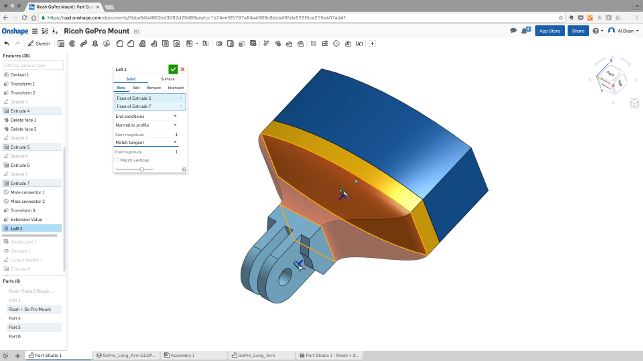

In fact, there are three flavours of app available at present. The first and perhaps most efficient is the “Integrated Cloud App”. This means that the third party application is similarly cloud-based and can run directly inside the Onshape window.

It also means that firing up and connecting your current data to that app will also create a separate Studio tab in Onshape — meaning that all of your data stays in one place and it’s kept up to date where possible.

The second category is the Connected Cloud App. Again, these are cloud applications, but you don’t use them within Onshape, instead either transferring the Onshape data to it or loading it across.

SimScale is a good example here. You’ll create a part or assembly, then connect it to SimScale by either loading the app from within Onshape and pushing the data to SimSCale for simulation or by pulling the data across from SimScale.

All of your work is then done using the third party service, rather than from within Onshape’s environment.

The last category is the Connected Desktop App. This is the case where you have a traditional desktop application, but either through the native interface or through the installation of a plug-in, it’s possible to pull down the Onshape data you want from the cloud and use it locally.

Infrastructure work

It could be argued that the real innovation in Onshape is not about the modelling tools, but rather the platform on which they’re built.

After all, modelling technology is mature and established workfl ows and best practices are already out there. It’s a case of Onshape filling in the blanks and fleshing out the toolset.

What really makes the system different is the underlying architecture that allows you to work in the cloud in a fully managed environment.

While much of this was set at release, it’s clear that with the user community growing, there are tweaks that can be made and potential to make it more effi cient — much of which has been carried out over the last few months.

One particular change is the consolidation of the version and history listing. This is now much more cohesive, giving you access to everything in one place with some additional tools on top of the existing Branching functionality.

For example, it’s now possible to insert a version when you need it, even if that point is days or weeks in the past of a project’s development.

Elsewhere, documentation of design decisions is much easier.

Finally, another big one for 3D CAD users is the ability to use your favourite SpaceMouse product (on both Windows and OSX).

Conclusion

Onshape has come on apace in the last few months.

The simple fact that the team is removing some of the limitations that hold back the modelling is going to move the system closer to becoming usable for more folks out there.

The examples we’ve cited such as applying operations to more than just bodies to now include features and faces, is the perfect case in point.

We all have a set of tools (and I mean, specific features and ways of working with those features) that we use daily and for a system to even be considered as a potential replacement, those tools need to be replicated and made available.

We’re not talking about a one-for-one match, but the ability to carry out the same tasks in the same way.

Simultaneously, the infrastructure is also evolving. The updates made to the version/history tree are super useful. Rolling the two into a single UI makes huge sense — as does the ability to create version retrospectively (something that would be near impossible with traditional document management tools).

We’ve not touched on Drawings or the new FeatureScript functionality (which we covered in the last issue), but it looks like Onshape is maturing. It’s gradual, of course, you won’t see huge leaps, but rather incremental improvements across the board.

If you’ve not taken a look at Onshape recently, log back in and see where things are at. Believe me, you’ll be surprised at how things are progressing.

Highlights of the Onshape App store

There’s a wide range of apps becoming available for Onshape, in a cloud integrated manner and connection to desktop applications.

Here’s a look at eight of them across a wide range of technology areas, from rendering to CAM, from data management to surface modelling.

It’s worth exploring these. Some will work directly within Onshape’s tab and document window. Some are direct cloud to cloud applications (opening the data directly in their own cloud application) while others enable a connection between the cloud and a desktop application. Almost all include some form of free capability.

There’s huge variance in the pricing for most. Some are quite costly, some have a pay per use model (either in terms of compute hours or export.

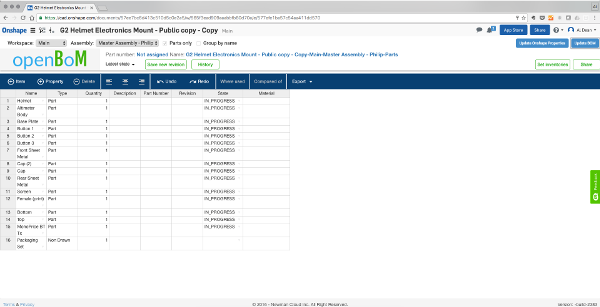

Product: OpenBOM

Supplier: NewmanCloud inc

Connection: Integrated App

Notes: The Bill of Materials is key to every project, Onshape doesn’t have a full BOM tool. Newman Cloud has stepped into provide a cloud-based way of capturing the BOM from Onshape models, extending it with non-drawn parts and enabling collaboration around it. A good solid tool beyond excel or google sheets.

Web: openbom.com

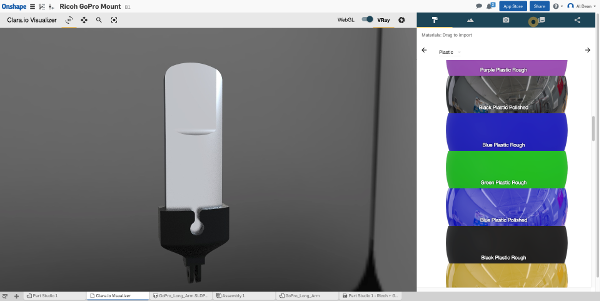

Product: Visualizer

Supplier: Clara.io

Connection: Connected Cloud

Notes: One of a couple of rendering services Clara.io’s Visualizer is built on a cloudinstall of V-ray, comes with a number of preset materials, environment and view controls. Output to HD sized images. If the quick renders aren’t enough, you can cross load into the full application when you need it for further work.

Web: Clara.io

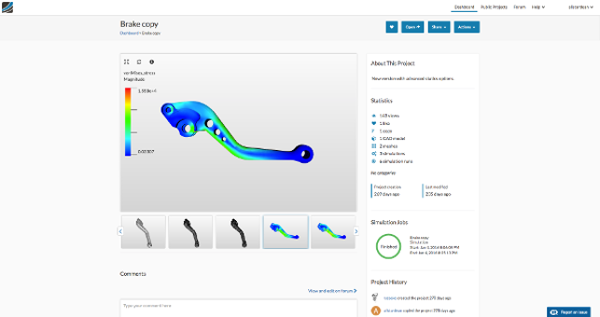

Product: SimScale

Supplier: SimScale

Connection: Connected Cloud

Notes: SimScale is building an incredible set of advanced simulation tools that allow you to work with the physics models you need, rather than what you have licenced. The direct connect to Onshape makes it a perfect partner application — with greater integration to come. We looked at SimScale in the January 2016 issue.

Web: simscale.com

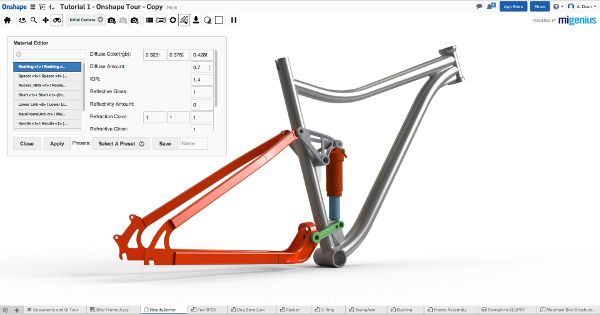

Product: RealityServer

Supplier: MIGenius inc

Connection: Integrated App

Notes: RealityServer is similar to the Clara.io application — it’s a cloud renderer, but this one is using the Nvidia Iray engine. You fire it up, load your data and start the session. This will load your data, tesellate it and allow you to change material property, environment and render out imagery. It’s basic, but works nicely for simple images.

Web: migenius.com

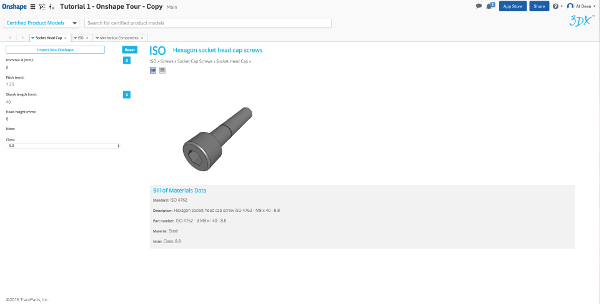

Product: 3DX Trace Parts

Supplier: TraceParts

Connection: Integrated App

Notes: TraceParts needs little introduction. It’s a comprehensive set of standard fasteners. Sign up for the application, load it up from within Onshape, find your M6 Cap socket screw and you’re done. Simple as that. Fully integrated and ready to go, just as you’d expect. The parts are stored as a Part Tab.

Web: traceparts.com

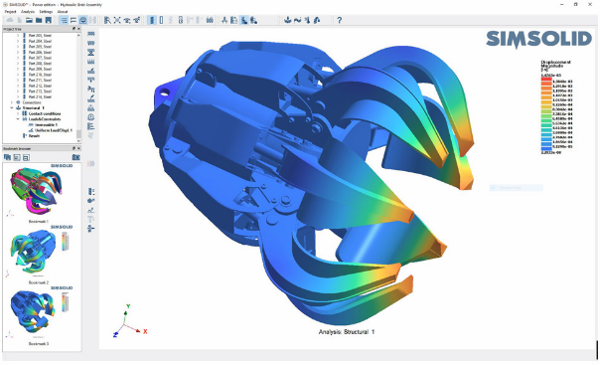

Product: SIMSolid

Supplier: SIMSolid

Connection: Desktop App

Notes: SimSolid’s mantra is simulation without the burden of geometry simplification and meshing. While we’ve not dug into the benefit of the company’s approach, there’s plenty to go at, particularly if you’re working with large and geometrically complex assemblies. It works by pulling your Onshape data directly into the desktop app.

Web: simsolid.com

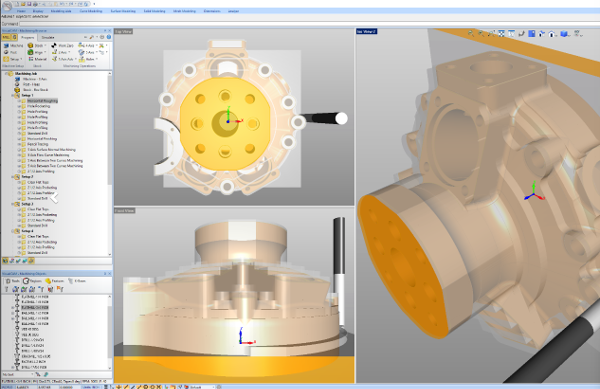

Product: VisualIMPORT

Supplier: MecSoft

Connection: Desktop App

Notes: VisualMill gains a plug-in that connects it’s CAM tools for CNC programming to Onshape’s data creation tools. If you’re at the maker end of the spectrum, the entry level version gives you basic tools for free (Very basic 3 axis) but there’s a clear upgrade path for more complex tasks and machine programming, up to 5 axis and beyond.

Web: mecsoft.com

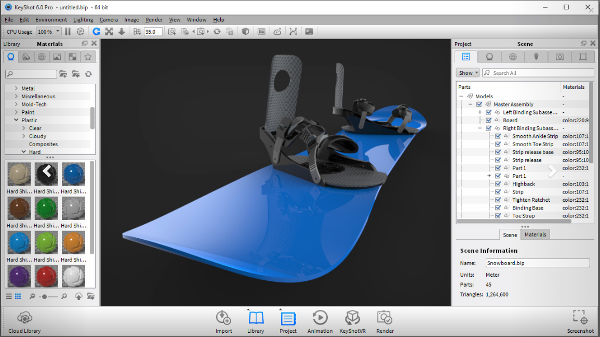

Product: KeyShot Connect

Supplier: Luxion

Connection: Desktop App

Notes: Exactly as you would imagine for everyone’s favourite rendering system. Pull your Onshape data from the cloud, bang it into KeyShot, render it. If your design changes, then KeyShot connect can propagate the design changes where

needed and update the geometry, retaining the materials where possible.

Web: luxion.com

| Product | Onshape |

|---|---|

| Company name | Onshape |

| Price | Free to $100 per month |