Frustum Generate – With topology optimisation all the rage in design technology, there are a wealth of solutions available. We take a look at new solution that uses the cloud to crunch those numbers and help you achieve the optimal result

Greater awareness and advances in additive manufacturing have brought about a heightened interest in topology optimisation over the last year or two. You’ll nary find a new CAD system release that doesn’t include it in some form and recent releases in the simulation world have also seen the same.

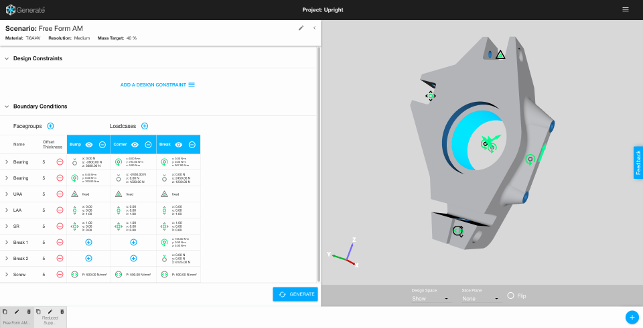

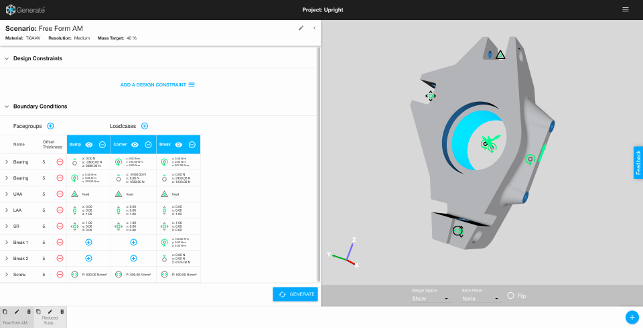

Frustum’s Generate allows you to define multiple load cases, all of which will be factored into the computation of the final result

Much of the reason for this is that with additive production methods (specifically in the metals field), you now have the ability to actually produce those forms that topology optimisation algorithms are known for.

One start-up that’s exploring the world of topology optimisation is Frustum. Founded by Jesse Coors-Blankenship a couple of years ago, Frustum has developed a set of tools that allow you to quickly upload a design space model from your CAD system, apply your boundary conditions and load cases, then use cloud computing to create your optimised form.

What’s interesting is that the service also addresses the age old issue of what to do with that geometry once your solution is found.

Users of both Solid Edge and NX might also have seen the same technology at work in their most recent releases, as Siemens PLM has integrated it into both.

Frustum Generate – project set-up

As with any topology optimisation tool, the start point for Frustum Generate is your design space model. Here, you’re looking to ensure that you’ve combined any required features (in terms of constraints, loading features) with the geometry available for the algorithms to work within. If you’re working on a redesign of an existing component, it’ll mean adapting your current design.

If you’re working on a clean sheet project, it’ll mean modelling it up from scratch. This would typically be done in your workhorse CAD system — as long as you can export a STEP file, you’re ready to proceed.

When you log in to Frustum Generate, you’re presented with a pretty standard interface, pared down to focus on the problems you’re working on. There are no community aspects or shared models in this instance (which is a good thing to my mind) other than four tutorial projects to assist with learning. To begin a new project, hit the large ‘plus’ sign and you’re asked for a project name, a BOM ID and your STEP file’s location.

The system then switches to your project definition page. To the right, you’ll see the model display and face selection tools. To the left, you’ll find the tools to define the loading conditions (referred to as load cases) in terms of loads, constraints and such. Generate’s workflow features face groups. Select these in the model, grabbing each that you’ll need for each type of constraint, then add them as a face group, giving them a sensible name.

Once these are set-up, you’ll start to define the loading conditions. Frustum at present has a number of options here, the range of which is growing with each release. In terms of loads, you can define forces, pressures, bearing loads and torques. In terms of constraints, you have fi xed, planar and linear sliders. Each is given a value and a vector.

Constraints are particularly key, as you need to define an offset value for the geometry. This will essentially protect those features so that they remain — this will be particularly useful for mounting features. Within each study, you can define multiple load cases, all of which are taken into consideration in the final form.

The final step in this stage is to define design constraints. These allow you to add in a plane of symmetry (you’ll need to upload the geometry already prepared) as well as two other options. The first is overhand prevention. This forces the system to avoid creating internal voids that would be difficult to manufacture additively.

The other is an ‘extrusion’ option. This will force the system to build parts that have a uniform profile in the given direction. When considering additive manufacture, this won’t make much sense, however it does make sense when it comes to machinable forms, particularly if you’re looking at sheet metal like forms or machined brackets and such.

Once all of these are set up, you’re ready to send the job to compute. The final few options you need to define are the materials (there’s a number of options, including titanium, aluminium and an ABS plastic) and the target volume reduction and the mesh quality. Coarse meshes will calculate more quickly but higher quality meshes will give a more accurate result.

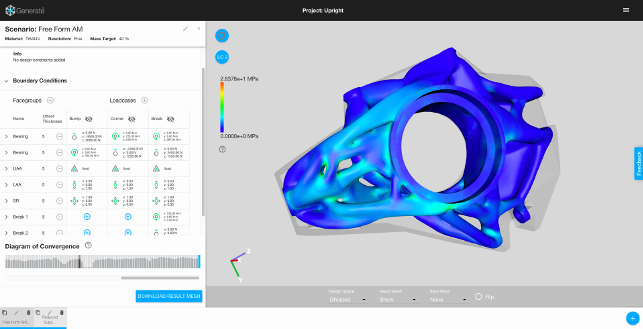

Frustum Generate provides users with FEA-based validation tools to see how current iterations perform according to the already defined load cases

Results & next steps

You can now leave the system to do the computation work. If you keep the window open, you’ll see the system creating multiple iterations in two stages, as these progress towards a converged solution.

The first is to capture the broad design at a low resolution quickly, while the second stage is to refine that broad snapshot at a much higher resolution for better accuracy.

If you’ve already used topology optimisation, you’ll be used to seeing a mesh-based form that’s a bit rough and ready. This isn’t what you get from Generate at all. The end result is a smooth, contoured model that is pretty much ready to go. Frustum creates these by using a volumetric approach, which enables it to create transitions between the hard, defined edges and the optimised forms more easily.

Also in the results mode, you’re able to slice the model as well as display the FEA results that takes the load case and applies it to the end result.

More than likely, you’ll want to be able to experiment further with the results by perhaps tweaking the constraints, trying to remove more material or anything else. At the bottom of the screen, you’ll see your study with a number of options — one of these is to clone the study. This allows you to vary the variables as you need and resolve.

It’s interesting that the system doesn’t let you override the existing results, rather requiring that you start afresh, albeit by copying across your set-up.

While that might sound counterintuitive in today’s world, it does ensure that you have a fully traceable set of results as you fine tune your study.

Conclusion

Frustum Generate is at a very formative stage and updates are frequent and often bring new tools, so it’s worth familiarising yourself with it now (particularly as there’s no cost barrier at present) and then keep checking in to see how things have developed. In the last release, we saw the number of loading types expanded from force/pressure to include torques and bearing loads.

In terms of usability, the system is pretty stripped back and it benefits as a result. There are no overly complex dialogs, rather a simple mechanism to define your inputs and variables and get the cloud to do all of the number crunching for you.

In terms of cost, the free level allows you two projects and 100 credits in terms of computation per month. The real restriction is that you can’t download the result mesh form.

To open that up, the next step is $100 per month. This gets you unlimited projects, storage and the ability to download. You still have 100 credits, but these will typically last a fair old while.

If not, they can be added to if needs be (though pricing on these isn’t too clear at present).

There is also an enterprise subscription, which adds in the ability to run on your own IT infrastructure, Amazon’s GovCloud and the like, but this will certainly be a big ticket item.

Considering that, at the time of writing, we’re only on version 1.4, Frustum’s Generate is a good solid offering for those who want to delve into topology optimisation but are also looking for a CAD neutral solution and usable results out of the box, rather than requiring remodelling in a CAD system.

Topology optimisation isn’t a new field, far from it in fact, but it is gaining interest in a number of sectors. Sometimes for novelty, but in many cases, there are some real use cases and proveable benefits to using it.

Whether that’s lightweighting to save on material costs, energy or fuel consumption, to provide competitive differentiation or another reason, more and more organisations will be evaluating its projects and looking for areas that can be improved.

What’s interesting is that Frustum Generate supports the inevitable experimentation that these organisations will need to go through to learn how to make use of it and where it can be applied with the most benefit. The development of the design space, in particular, is a subject that’s rarely understood well, so a lot of learning needs to be done to make the most of these tools in specific instances.

It’s also interesting that, from the off, the company has also realised that this type of technology isn’t just restricted to additive manufacturing and can prove beneficial to many other areas and production means.

| Product | Generate 1.4 |

|---|---|

| Company name | Frustum |

| Price | See text |