Onshape Q1 2019- A look at how the cloud-based system brings a new approach to data and workflow management as well as new design and engineering tools

The last time we took at look at Onshape, the company had just updated the system to bring a brand new set of tools for sheet metal, standard components, configurations and more.

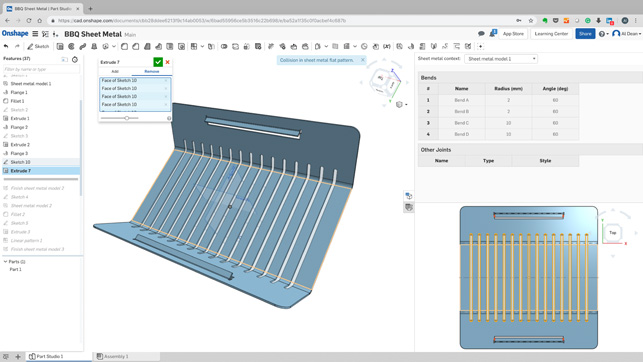

Sheet Metal’s simultaneous flat pattern now lets you make feature edits to the unfolded form that are instantly reflected in the folded form

Fast-forward a scant 12 months, and we find a system that has grown and expanded its existing functionality, and started to push out into new territory. So without beating around the bush, shall we dive into where things stand a year on?

Release management and workflows in Onshape

The first thing that we’re going to look at is the incorporation of release management and workflow capabilities. While in other systems, this might have been something addressed as part of a wider data management add-on, things in Onshape are, as I’m sure you’re aware, a little different.

Due to its cloud-based nature and how the system has been built, there’s been constant tracking and version management of all your data from day one and from the very point of its creation. This has always been available in tools such as part histories, and it’s what enables the flexible modelling tools already in the system.

What the release management and workflow tools now add is the ability to formalise this tracking and version management and turn it into a set of tools that better suit the more specific management and stage-gated tool requirements of engineering organisations.

In the first instance, the release management tools allow you to define your release conditions and part numbering and to take advantage of predefined workflows, approval conditions and so on, in order to get the most out of your team’s work.

What’s interesting here is that while these tools will always need a little time to set-up, Onshape has removed a lot of the donkey work involved in setting up and configuring a PDM system and lets you focus instead on the business end of the process.

Enterprise licensing

While the release management tools are useful for larger companies working in a more structured manner, Onshape had to date been focused on providing a set of tools that addressed a very distinct set of users, particularly those not looking to engage in the heavier forms of enterprise licensing and happy to have users administering their own seats.

Of course, for the larger company, and particularly those that have much tighter security and financial controls, this wasn’t particularly useful. There was no centralised administration of licences and no centralised user management, for example.

As a result, when Onshape introduced the Enterprise option for licensing back in May of 2018, it made some large organisations sit up and take notice.

Essentially, this new option brings the full set of tools that a larger company is going to need as standard. That ranges from a singular domain (think “yourcompany.onshape.com”), rather than the generic one; two-factor authentication as standard; auditing and analytics (which are particularly interesting for reasons we’ll explore shortly); as well as a whole host of project- and role-based access control tools. It also includes a brand new user type that’s perfect for those who need interaction with workflows and data, but not creation or edit rights.

Now, the analytics are interesting in this instance: while other 3D design system vendors have introduced some element of analytics or system use monitoring in recent years, this is the first time that you’ve had the same level of granularity that you’d find in the likes of Google Analytics.

Because of Onshape’s nature, the management team is able not only to peep into the state of their projects and data, but also gain a deeper, more holistic understanding of how the team is working, both individually or as a group.

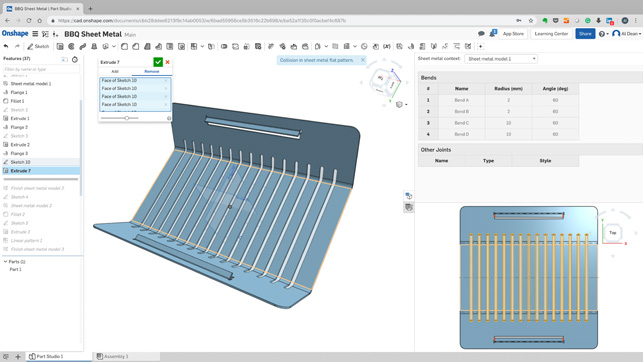

Bill of materials (BOM)

This is an update that’s more functional, rather than administrative, but it’s equally important as Onshape aims to become more suitable for larger organisations.

As we all know, much of the engineering and manufacturing process is driven by the BOM as much as it is by the geometric engineering drawing.

In other words, BOMs are the lifeblood of many organisations, allowing other departments to start to plan their own activities before products are finalised.

The issue here is that BOMs are, in these 3D CAD-driven times, often inextricably linked to the engineering model, so are often delayed until the model is ready to go.

While Onshape hasn’t changed this state of affairs, it has made preparation of accurate and complete BOMs much easier.

Onshape’s iterations of BOMs are available in the Part Studio environment initially.

There’s a tab to the right of your window that will pop the BOM view open. It’s here that you’ll find a difference between how BOMs are usually constructed and how this is handled in Onshape.

Essentially, these aren’t simply a derivative of the drawing, as they are in most modelling systems, with the table extracting information from the 3D assembly. Here, they are a live part of the model, linked to each part’s metadata. That means you can either fill out your part’s metadata in the properties dialogue as per usual (or have some of it, such as part numbers, auto-generated), or you can fill it out in the clearer, more focused BOM view in the Part Studio.

The new bidirectional BOM is useful in both the part studio environment as well as the more typical drawing environment

Modelling & drawing updates in Onshape

While this area includes the three biggest updates to the system since we last looked at it, there have also been a consistent set of smaller updates over time (remember, Onshape gets a release every month).

These have already brought some very nice enhancements to existing functionality as well as brand new capabilities – and they’re all focused on both modelling and documentation such as drawings.

While the core set of tools in Onshape is developing nicely, long-term users will be looking at finer points of control, how feature options are being fleshed out and what the raw modelling capability of the system is – particularly in comparison to their existing systems, some of them 20 years old or more.

Parting Line Draft: Building draft into a part is one of those processes that typically comes at the earliest possible stages of design. That’s been best practice for decades, driven by linear history-based modelling systems (draft early, fillet late).

And while the majority of modelling features in Onshape allow you to create draft at a part’s point of creation, there are times when you might want to add it after the fact.

Onshape’s standard drafting feature has been there for a while, but the new addition of a ‘Parting Line’ draft makes huge sense. This allows you to define a draft either side of a set of parting lines in your model (readily created using the face split operation).

As you work on more complex geometry, you’ll find what it can handle diminishes (that’s down to simple mathematics, not the system), but it lets you do some interesting things. It’s particularly useful, for example, for those users who like to block out form, then add in manufacturing considerations after the fact.

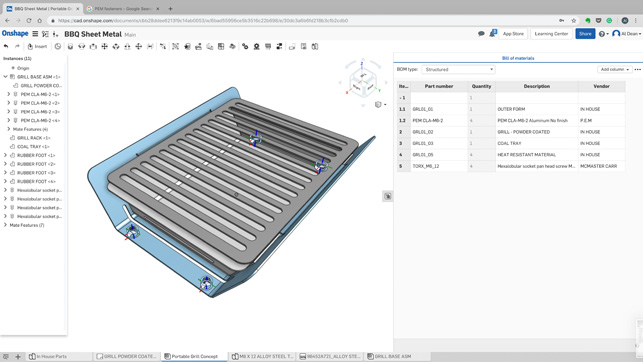

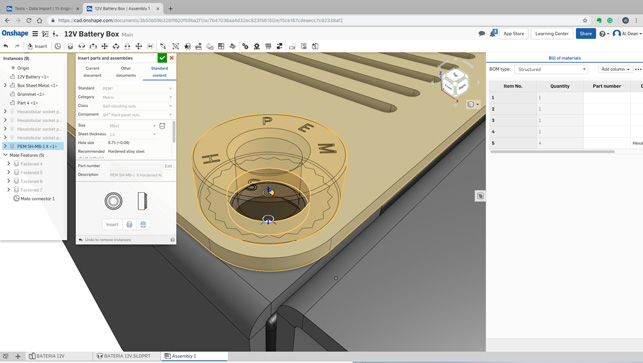

Standard Content: There have been some good updates to the Standard Content capability introduced early on in 2018. While this initially focused on standard fasteners along the nuts, bolts and washers line, there’s been an expansion of the selection of standards (DIN support has been added this year) and fastener types (to include pins and retaining rings) that are supported.

There’s also been an effort to include more specialised fasteners, particularly those conforming to the National Aerospace Standard (NAS) for clinch and flush nuts and standoffs, as well as a good basic selection of PEM fasteners.

It’s also worth noting here that when you use the standard content tools (which are found in the ‘insert’ operation in an assembly studio), the system can automatically generate a useful part name, which handily adds in details of type, size, length and so on.

Drawing & documentation updates: Drawing creation has seen a lot of work over the last 12 months. There’s been a fleshing-out both of the types of views you can add to your drawing sheets, as well as the documentation that can be added.

The addition of the drawing properties panel (in line with other panels in Part and Assembly Studio) gives you quick access to all of the properties of your current drawing sheets, making fine-tuning them much easier. In terms of expanding the types of views you can create from your 3D model, both broken views and cropped views are new to Onshape, allowing you to focus in on detail that matters without taking up huge amounts of a sheet.

There’s also been a concerted effort to add in smaller details: a wider selection of shapes for assembly balloons or callouts; the ability to pull more than just a part number into those details; greater arrowhead controls; and work on how you define bend notes for sheet metal parts.

There’s also been a lot of work done around tables; as you might imagine, these focus on reusing BOM data from the Part and Assembly studio environments. As well as allowing you to bring these across, the system also gives you greater control over the layout of those tables, so you can get them to match exactly your company standards.

Importing Geometry: This is an area that’s always important for those users looking to supplement an existing workflow with Onshape, or seeking to switch systems, or working with imported data from clients, suppliers and the like.

Onshape had a few eccentricities on launch when it came to importing assemblies. These have now been addressed, with much clearer presentation of your options when you start the import process, to ensure that you get what you want and in the orientation you need.

There’s also been a bit of update work performed on import formats, with the system now supporting import of Rhino 6 data, as well as the import of assemblies from both Inventor and Catia. That’s important, because both systems require that all of files are contained in a zip file where the zip’s filename matches the toplevel assembly name.

Standard parts functionality has been enhanced in recent releases to include proprietary fasteners such as PEM hardware for sheet metal and PCB mounting

In conclusion

Onshape has, in the last year, been through some serious updates and enhancements, both at its core, with its modelling and drawing creation tools, but also in terms of the size and complexity of organisation it is looking to attract and support.

For smaller shops requiring only a couple of seats, the Standard plan (at $1,500) will probably suffice. But as soon as you start to add in version management and workflow-based sign-off processes, you will need to step up to the Professional licence, which is priced at $2,100. As is typical with the cloud-based software model, prices are charged on a per-user, per-year basis.

Then, if you want to take advantage of the Enterprise capabilities in Onshape, you’re looking at around $20,000 per year as a minimum starting cost.

This is all interesting, but I’m not going to make a call here comparing these costs to those of more traditional data management systems. After all, these systems often come with costs relating to lengthy implementation times. If you’ve been through that process in the past, you’ll know how that often ends up.

What I will say is that Onshape’s ongoing development and maturation is interesting to watch. The tools themselves for defining, testing and documenting a product are becoming richer as each month passes (and this is something that’s very easy to miss in the rapid-fire monthly release cycle).

At the same time, the infrastructure to support more complex products in Onshape (in terms of traceability, version control and on) and its inherent organisational infrastructure is also maturing nicely.

| Product | Onshape |

|---|---|

| Company name | Onshape |

| Price | $1,500 pa |