If the German industrial designer Dieter Rams had his way we’d be living in a world where everything is classically minimalist and pretty basic to model. But we don’t and many products in our world are organically shaped and require added detail.

For instance, in the structural packaging, signage or jewellery industries complex geometry is often the name of the game. And its here that the mainstream 3D design tools let us down. While perfectly suited for analytic surfaces, solid features and the like, they can’t handle complexity.

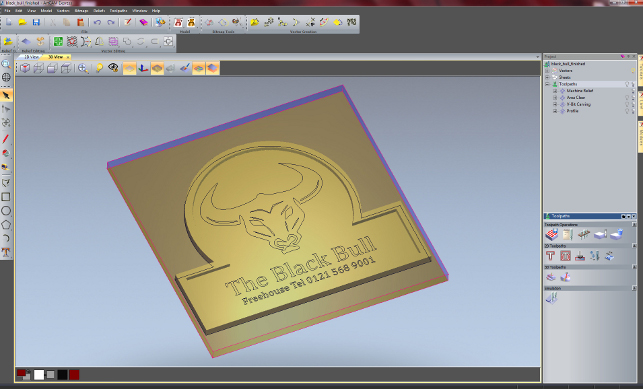

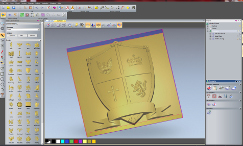

Delcam’s ArtCAM has been on the market for almost 20 years and it has been serving its industry niche very well. Using the concept of ‘relief’ modelling, it provides tools that allow the creation of complex geometry from very rudimentary sources (such as vector drawings) as well as sculptural modelling techniques to add, remove and smooth geometry dynamically.

However, while accepted in many circles as the de facto choice, for others the cost of entry has been more than a little high – particularly considering the rapidly falling cost of machine tools, such as CNC laser cutters, and routers, that can also carry out such work.

With this in mind, Delcam has released ArtCAM Express, an entry level tool for just £99. To enable this, the company has stripped back the basics within the system to simple design work using bitmaps to build geometry and basic 2 and 2.5 axis machining.

There are then a host of add-on modules that bring additional tools to the system.

The first stage is to set-up the job at hand. This can be done by importaing 3D geometry within the entry level version as it can’t be created it from scratch. This requires dimensions, a material zero for datum and, of course, units. The next stage is to create the ‘geometry’.

Vector led

ArtCAM’s relief based processes use simple vector illustrations as the basis for the profile geometry. These can be pulled from the user’s own artwork or from stock images found or acquired (depending on copyright).

The system will trace the outlines and create a nice profile from even the most pixelated images. Noise can be removed and the vectors adjusted to fine tune them.

3D relief

At the base level, ArtCAM is supplied with a raft of 3D reliefs that can be dragged, dropped, combined and generally mashed up to create the relief needed. There’s a whole host from diamonds to donkeys and many plaques and other decorative items in between.

To import new ones, there are online sources, many of which supply them in Delcam’s own ArtCAM format for quick insertion. To add text and lettering, the system is supplied with a special library of ‘machining’ suitable fonts.

These match standard Windows fonts but are adapted to ensure that they can be cut with a mill.

Machining

Once the project is complete, it’s time to start machining it.

Here, much of Delcam’s mastery of NC programming comes to bear. The Project window to the left of the user interface provides a list of toolpaths and operations available within ArtCAM Express.

2D profiling and area clearance is a given, but there are also specialist operations for V bit carving (for engraving work and fine detail), cutting of inlays and a very basic 3D toolpath for more complex geometry and sculpted forms.

The system supports both classic 32bit and newer 64bit operations, something that some more mainstream CAM vendors have yet to add.

Alongside the standard machining operations, there’s also support at this base level for laser cutting tools, which makes huge sense considering how the price of a laser cutters have now dropped to within reach of the hobby market.

Interestingly, the system can save out an image from the simulation to show exactly how the finished part will appear.

This can be useful for both checking before cutting, but also to communicate intent if the user is quoting for a job or requires sign off.

When the operations are ready, the final stages are simulation, with the familiar material removal display as a sanity check and then the G code is outputted to the user’s machine.

Delcam has added support for the majority of machines out there, but it shouldn’t take too much to adapt the post to a special or non-standard machine.

It’s important to note that the system will support both those machines requiring a manual tool change, with separately executable files, and those fitted with an automated tool changer.

Upgrades

While the entry level product is impressive, the package upwards is the £1,700 ArtCAM Insignia. Cearly a bit of a price difference.

But between these two versions, there is the ability to buy online modules providing extra design and machining capabilities.These range in cost from £100 to £500 so, in many ways buying the Insignia version looks a better deal.

In addition, Insignia provides greater support for automation, panel machining to split up large pieces, drill bank support, more intelligent toolpaths and greater import/export options.

Conclusion

ArtCAM is one of those tools that you see, play with and think “Damn, that’s impressive”. It allows you to create the types of geometry, details and organic forms that would simply be impossible to do using a mainstream modelling system.

The entry level offering means that it is within reach of many companies and could even be put to use with the machine tools currently in place.

The fact that there’s a clear upgrade path to add more capability and automation shows that Delcam has thought about how a user might progress.

ArtCAM Express may be enough for many, but if it isn’t, there will be an option, right up to the all singing, all dancing ArtCAM Pro that’s comparable in price with more mainstream design systems.

Excellent work again from the Delcam team who seem to be adept at finding niches that many vendors miss, working their way into them and creating tools that are unique, engaged and ultimately, usable.

| Product | ArtCAM Express |

|---|---|

| Company name | Delcam |

| Price | From £99 |