Tired of all the hype around consumer or hobbyist 3D printing? Tanya Weaver certainly is and thinks it’s about time that this trend du jour is knocked off the top spot of the technology hype cycle

Around twelve years ago, as a naive and somewhat ignorant engineering journalist, I visited German additive manufacturing company EOS at its UK offices. Having discussed the technology I was handed an off white, gritty object of a small intricate ball inside a bigger but equally intricate ball. I must admit I was a bit in awe, “how could they possibly achieve that?”

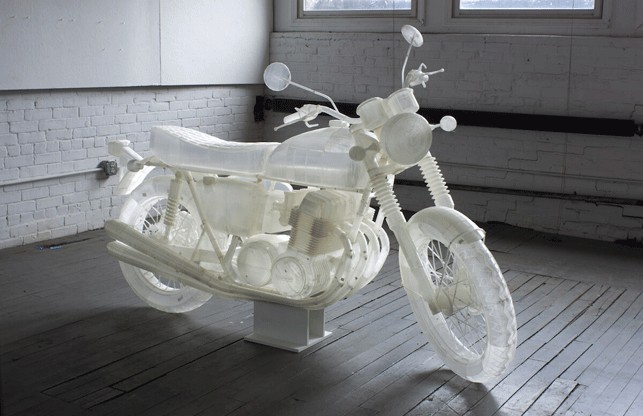

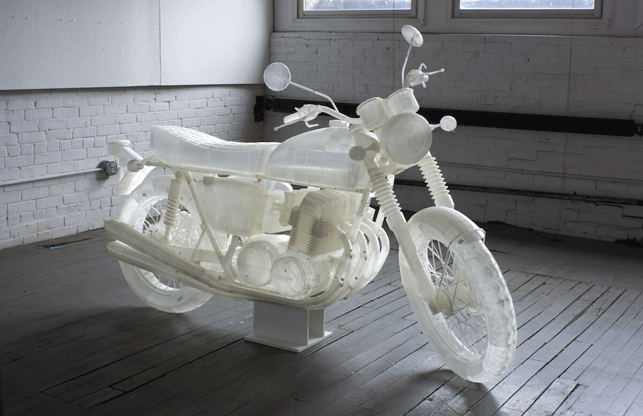

Jonathan Brand, an artist from New York, created a life-size 3D printed 1972 Honda CB500 motorcycle using his two Ultimaker 3D printers

That was one of my first encounters with the technology. Back then when it was called rapid prototyping it was an extremely useful tool used by designers and engineers to create prototypes during the product development process. It still is, of course, but as the technology has become more sophisticated so have the machines shrunk.

Having emerged from factory floors and design studios and into the home and onto desktops, these 3D printers, as they became known, have been touted as a technology for everyone.

It feels as though a new consumer or hobbyist 3D printer is unveiled every week or at least a new campaign for one is launched onto Kickstarter. The hype is still phenomenal and many believe that by feeding your beautifully clean 3D printer, which quietly hums in the corner of your living room, with some energy and raw materials an object will magically materialise.

DEVELOP3D readers know this isn’t true. A gulf exists between hype and reality but that hasn’t stopped the mainstream press going gaga for this trend du jour.

We’ve been subjected to the media reporting on everything from 3D printed guns, to chocolate, bicycles (lots of them), unborn babies still in the womb (yes and for a hefty price too), selfies, and Sad Keanu models (just Google it to see how ridiculous it is and why anyone would want one).

But one thing that the word 3D printing will guarantee is publicity and free advertising. Just the #3Dprinting hashtag in Twitter alone will ensure retweets, favourites and new followers.

I’m not saying I’m innocent in all this. I’ve often clicked on a link in a 3D printing-related tweet as fodder for our magazine or blog. I did just that recently for a 3D printed motorcycle, which annoyed me a bit and was in fact the inspiration for this comment (rant).

Ultimaker, a Netherlands-based company that launched in 2011 and has become a big player in the home consumer 3D printing market, posted a link to a video of the aforementioned 3D printed motorcycle. But as soon as I started watching the youtube video it became very clear that this was an exercise in art rather than one in engineering.

New York artist Jonathan Brand had used his two Ultimaker 3D printers to create a full-sized replica of the classic 1972 Honda CB 500. It was a painstaking process that involved not just the printers but an array of tools including Rhino, Netfabb, Geomagic, Kisslicer, 3D Studio Max and Adobe Illustrator.

To create the desired translucent effect he wanted each section to only be a millimetre thick. In the video he claims this project was not straightforward as getting his hands on reliable quality printing materials was a problem (we’ve heard that one before).

However, he managed it and the overall motorcycle consumed a hefty 18kg of PLA filament with all sections being very carefully glued together.

I know I’m probably coming across as cynical.

I’m not disputing that as a work of art it is very impressive but I also can’t help asking whether it’s worth all the money spent in terms of materials and electricity just to prove that it can be done? Maybe it was.

One thing that does bug me about hobbyist or consumer 3D printing is that in many cases it’s not used to print off anything useful rather it churns out all manner of little trinkets, widgets and frankly useless tat. Where does it all go? In the bin presumably.

But companies are still plugging away at this market. One of the most recent being London design agency Conran & Associates, which has designed the rather smart looking Vector 3. This 3D printer can in fact be built by the ‘layman’ and then used to print all sorts of small things.

All they have to do is buy 90 weekly issues of new partwork magazine by publishers Eaglemoss called ‘3D Create & Print’. At £6.99 a pop you’ll receive parts for your printer together with tutorials and instructions as to how the components fit together.

So, if you do the math – to build a 3D printer over two years will cost you over £700 in weekly instalments.

I’m sure for some there is an appeal to this in seeing a printer emerge in front of their very eyes, not to mention the satisfaction of having built it themselves, but wouldn’t they be better off saving that money and in two years buying a new 3D printer. The technology will no doubt have moved on by then.

In the meantime, I would like consumer 3D printing to be kicked off the top of the hype cycle and for something else to hog the limelight for a while. How about if sustainability came back — especially with all the waste that is being generated from all these consumer 3D printers.

A waste of time, energy, materials and money

Default