In its drive to create new products and bright new ideas for the electrical industry, Schneider Electric has turned to 3D printing to produce test-ready parts that help supercharge their design process.

Advanced new parts, such as housings for circuit breakers for low to high voltage, are developed and produced at Schneider Electric’s Openlab at its base in Grenoble, France.

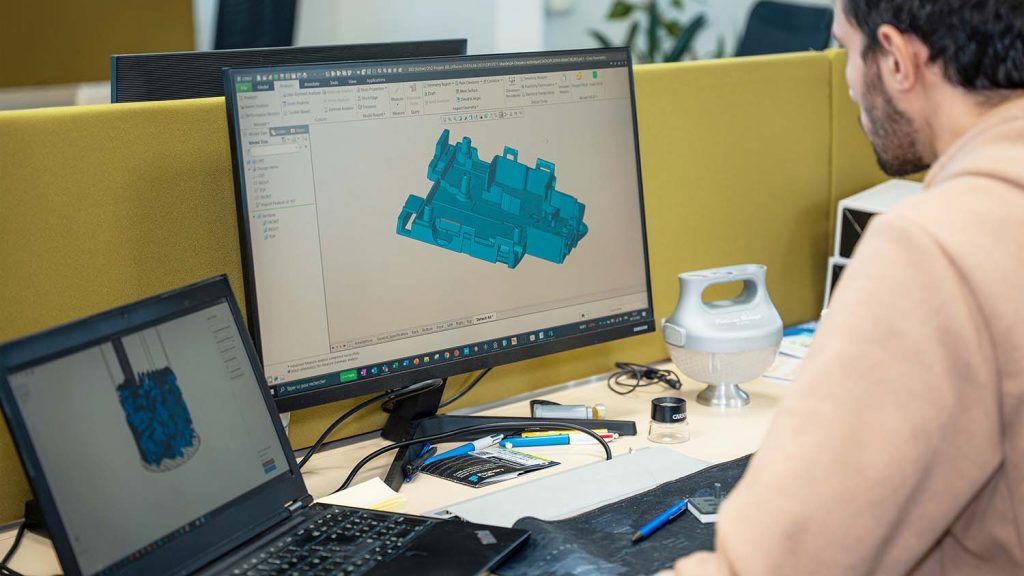

New parts are often prototyped here, while the digital technology available to the team allow them to reverse engineer existing designs. An example project is an entire interior for a low-voltage circuit breaker, a component found in most homes, which has been modified to make it more compact and to add new functionality.

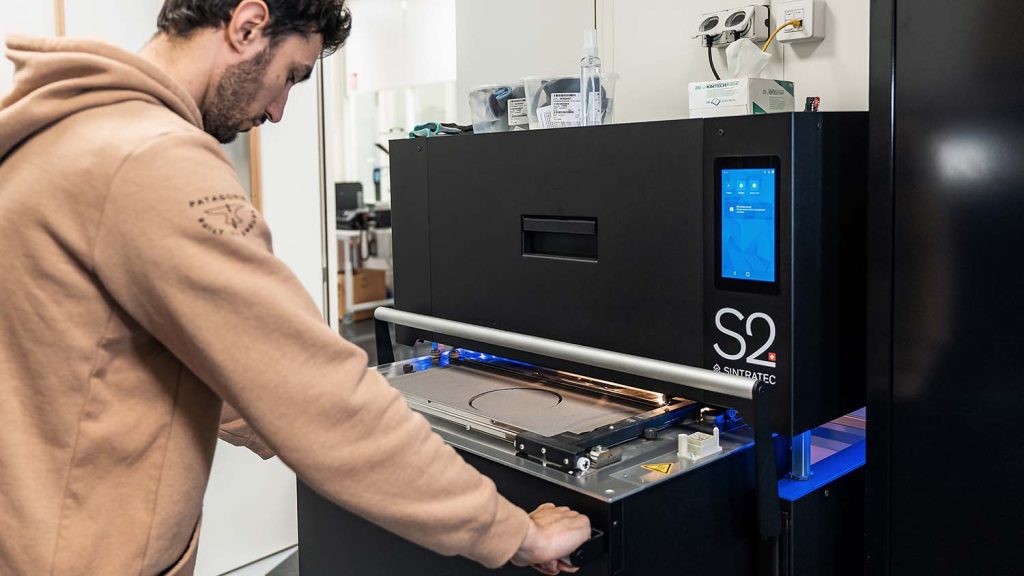

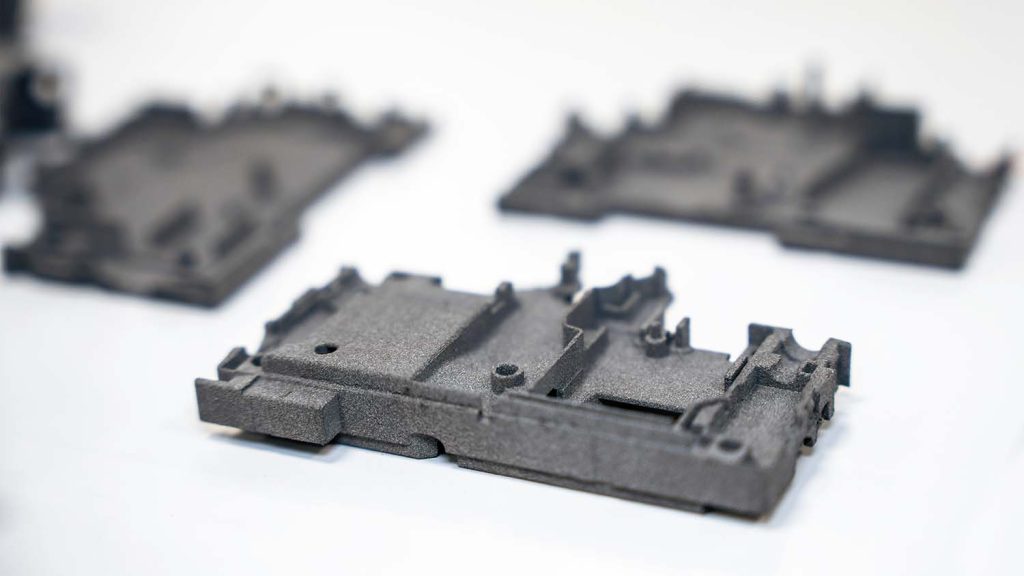

“We 3D printed the housing cover on the Sintratec S2 to test the assembly and check the components for interference so that we could validate the product», Brandon explains. Similarly, a box for communication and monitoring was quickly tested, adjusted, and validated through a laser sintered PA12 prototype.

Project leader for prototyping Brandon Alves says that the recent project utilised SLS 3D printing for the housing cover using a Sintratec S2 3D printer, allowing the team to quickly test the assembly and check the components for interference so that the product could be validated.

“I see the biggest advantage of SLS in the homogeneity of the parts,” he says. “We don’t see any layering effects or fragilities along the axis which makes it a very interesting technology for us.”

The Openlab features 12 different 3D printers that support the Schneider Electric design team in their R&D, but which is gradually moving towards production technologies, says Alves, with SLS technology proving valuable for evolving towards small series production.

“Our material for mass production is PA6, which is very close to the PA12 powder that we currently process,” Alves points out, explaining that its high precision makes SLS well suited for many applications in the electrical field.

The ability to densely nest multiple parts into one build using the Sintratec Nesting Solution is helping the Openlab pivot towards greater production numbers, and meet the growing demand for larger quantities of high-quality plastic components at Schneider Electric.

Sintratec Nesting Solution optimises its SLS tech for density