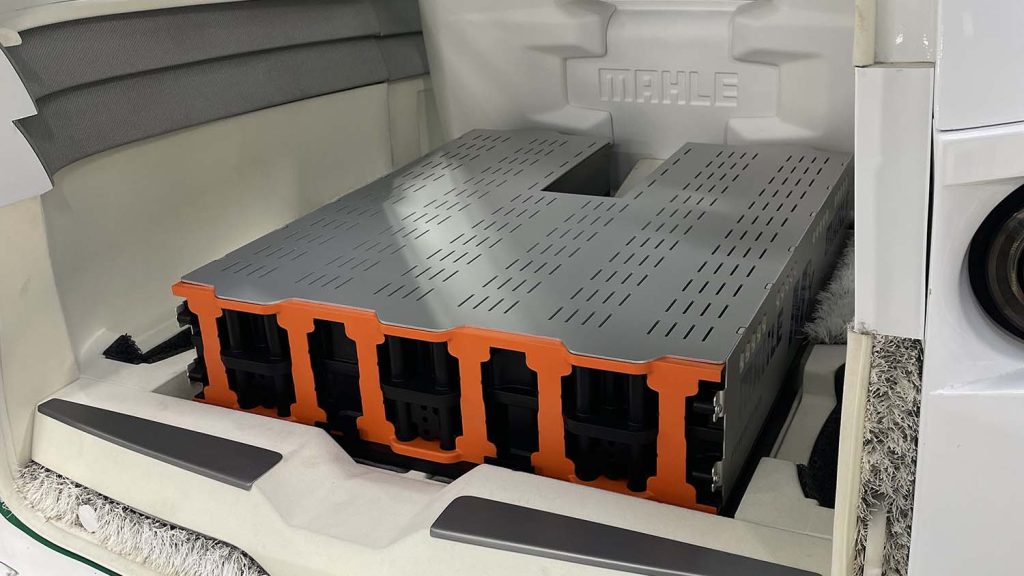

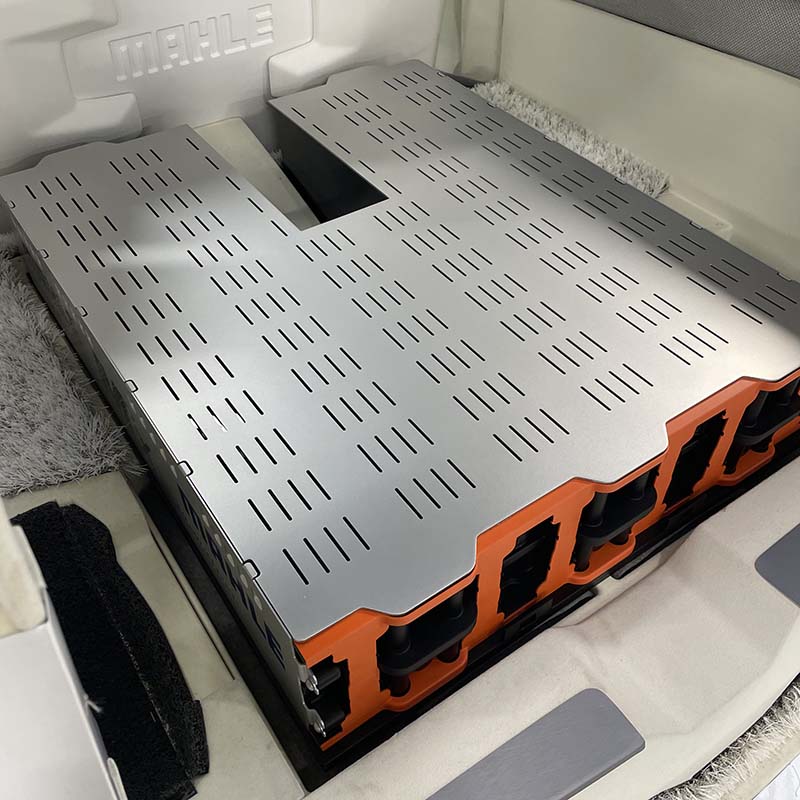

Utilising 21,700 lithium-ion cells with optimal packaging and thermal management, Mahle Powertrain’s cutting edge M3X battery solutions are technical wonders, but showcasing just what goes into these packages is tricky.

To showcase the full abilities of its M3X battery, Mahle turned to Malcolm Nicholls Ltd (MNL) to produce a high-impact exhibition model it could take to various events.

The goal was to show a detailed cut-away of an installed power unit within a vehicle, showing lots of the internal components including the individual battery cells and connecting electrical contacts. The CAD data of the real battery was sent to the team at MNL as a STEP file, along with the measurements for the demo vehicle where it would be fitted.

Using Solidworks, the features and geometry were simplified in 3D CAD, taking care to hide any protected IP and thicken up certain walls ready for being produced using 3D printing.

The team devised several model options and specifications that would offer levels of cost effectiveness without compromising quality, providing Mahle with a comprehensive presentation to help their decision process.

A hybrid construction was chosen to help maintain the desired strength and aesthetics, combining laser-cut acrylic walls with CNC-machined side walls to ensure strength in detailed and vulnerable areas.

“We worked very closely with the Mahle team to get the accuracy of the battery module. We were given dimensions of the recess in the boot of their demo vehicle in which the model battery was to be housed. We simplified the whole design in-house – it wasn’t easy but we were able to do it!” said Ross Nicholls, technical director at MNL.

3D printing using MNL’s Stratasys Neo 800 SLA machine, with a 800 x 800 x 600mm build platform, brought intricate details on the front of the model to life with superior 3D form accuracy. The entire model was painted, assembled in-house, with vinyl decals added to further enhanced the model’s visual appeal.

“The deadline was tight on this one, so we didn’t have any room for error,” says Nicholls. “We were even video-calling the client from the workshop as the decals were being placed, to make sure they were happy with the accuracy and finish!”

Within a swift timeframe the advanced battery technology was transformed into a captivating exhibition model – a showstopper, seamlessly integrated into a concept vehicle and made a focal point for exhibition visitors.

An added touch of sustainability is that the design of the model chosen by Mahle can be upgraded in the future to highlight new battery and connection features, making it an eco-focussed choice like EVs it helps power.