Soaring solar quest

The world’s first totally solar-powered aircraft, Solar Impulse 2, is currently grounded in Hawaii due to battery damage, but pilot Bertrand Piccard hasn’t given up on his dream of circumnavigating the Earth without using a single drop of fuel.

Solar Impulse 2 has already broken aviation records for the longest ever solo-pilot, non-stop flight, as well as the longest solar-powered flight by both distance and duration

In fact, by the time the mission ran into problems in early July, Solar Impulse 2 had already smashed several important aviation records, including the longest ever solo-pilot, non-stop flight and the longest solar-powered flight, both in terms of distance and duration. Piccard has vowed the journey will resume in spring 2016.

With a 72-metre wingspan – the same as a Boeing 747 – and four 17.5 hp engines, the design of Solar Impulse 2 cleverly juggles a number of trade-offs in order to satisfy the stringent weight-to-power ratio required to get it off the ground. It was created in Dassault Systèmes Catia, using Enovia to pull all the design and engineering information together.

The 17,000 solar cells, capable of collecting up to 340 kWh of solar energy per day, account for more than one-quarter of the aircraft’s overall weight. This clocks in at just 2,300kg – about the same as a Range Rover – thanks to a structure created from honeycomb composites by engineer Andre Borschberg and his team. As a result, Solar Impulse 2 is around ten times lighter than some of the best gliders out there. It also sends out a powerful message about the potential of clean technologies.

Says Borschberg: “Imagine energy reserves increasing during flight! To make this dream a reality, we had to make maximum use of every single watt supplied by the sun and store it in our batteries. We tracked down every possible source of energy efficiency. Today, Solar Impulse is the first solar airplane flying through night and day, the first aircraft to come close to perpetual flight.”

In the mix

Heavyweight industrial equipment is often associated with hefty energy consumption, exhaust emissions and noise pollution – but CIFA’s Energya E9 truck mixer is looking to change that.

Cifa’s Energya E9 offers reduced energy consumption, less noise and less pollution, but more freedom of movement

The 9-cubic metre drum on this electric-diesel hybrid is fitted with an electric motor driven by a smart lithium battery unit. The battery can be charged during road transport by the truck’s diesel engine or during loading and downtime by plugging it into a mains power supply.

The core technology of the hybrid drivetrain was developed in collaboration with the Politecnico di Milano, while an internal group at CIFA drew on naval and automotive industry expertise to create the weight-saving composite materials used in the Energya E9’s covers.

The design of the base chassis and metalwork was carried over from an existing cement mixer, with only small modifications made to the original 3D CAD model in PTC Creo. After sketching, the CIFA team used Autodesk Alias for surface modelling of the truck’s lightweight bodywork. A production-ready, parametric 3D model was then created using Dassault Systèmes Catia. For simulation, Ansys was used to run structural FEA tests.

With the Energya E9, CIFA won a Red Dot award for product design in 2014.

Little wonder

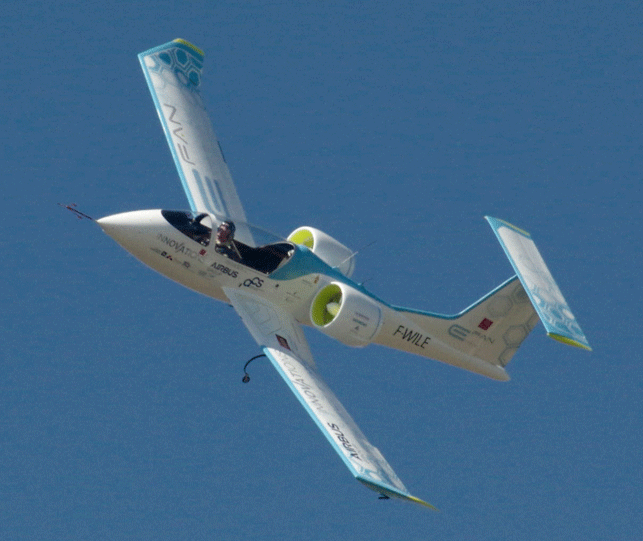

On 10 July 2015, the Airbus E-Fan took off from Lydd airfield in Kent and became the first twin-engine electric aircraft to cross the English Channel.

Powered by lithium-ion batteries, the Airbus E-Fan completed its 74km journey over the English Channel in around 37 minutes

First unveiled at the 2014 Farnborough International Airshow, the Airbus E-Fan weighs 600kg and can reach a maximum speed of 220 km/h. It’s set to enter service for basic pilot training in early 2018, but has a far more fundamental role to play at Airbus, serving as an ‘innovation platform’ for evaluating breakthrough aviation technologies.

Less than 7m long, with a wingspan of 9.5m, the E-Fan features two electrical engines driving shrouded propellers, with the energy provided by two battery packs located in the wings.

The design was created in Dassault Systèmes’ 3D Experience Platform so that third-party suppliers could collaborate on design and engineering plans. Dassault’s Simulia software provided accurate CFD simulation of the design prior to manufacturing.

By the time the aircraft made its safe landing in Calais in July, Airbus had already signed agreements with partners keen to participate in the industrialisation of the E-Fan alongside Voltair SAS, the Airbus Group-owned company responsible for developing, building and servicing future E-Fan models.

The design of three battery-powered vehicles

Default