It’s not surprising that many technological inventions are born in universities. They are after all a hotbed of research and innovation.

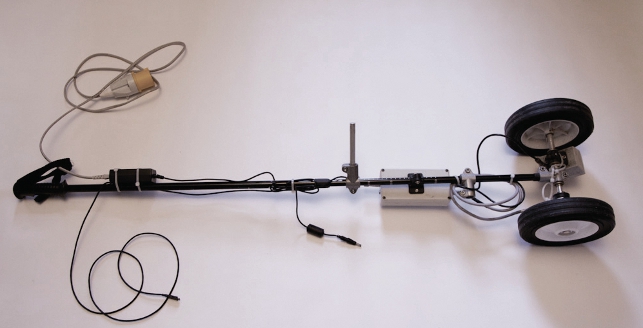

The first EMAD prototype developed at Keele University

But the challenge is taking these inventive ideas and developing them into successful products that can be delivered in the commercial world.

For example, for the past ten years a professor of environmental engineering, Peter Haycock, and his team of material scientists at Keele University in Stoke-on-Trent have been working on a method that uses magnetic techniques to locate rust damage in steel reinforcements within concrete structures such as bridges, car parks, brick/stone clad steel-framed buildings and pipelines.

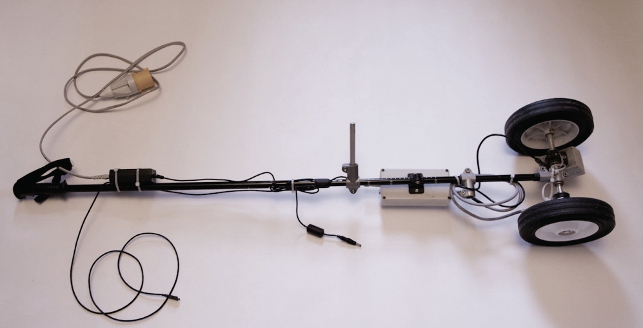

The spin-out company SciCorr was set up in 2012 to transform this Electro Magnetic Anomaly Detector (EMAD) into a commercial product.

Essentially EMAD is a three step process that uses two separate devices – a probe and a large magnet.

Firstly, the probe is rolled over the surface of the survey area taking measurements every six millimetres. This provides a ‘ground zero’ scan. The magnet is then rolled over the same area with its electromagnetic field energising or ‘exciting’ the steel beneath it. The probe then scans the area again.

The resulting data is retrieved from the probe via a USB connection and downloaded onto a computer. A map is produced that identifies the areas of concern by comparing the scans before and after the electromagnetic fields have been applied.

Professor Haycock and his team had developed a proof of concept prototype that had been used successfully on a number of field trials including the Hammersmith flyover in London.

But it was a flimsy bit of kit that essentially consisted of a probe strapped to a pole with two wheels on the end. It could not withstand the conditions of a construction site.

So, entrepreneur Bob Rennison was appointed managing director of SciCorr and tasked with getting this technology out of the university, turned into a robust product and into the marketplace.

Game changer

Rennison knew that the potential of this technique was huge especially as it offered significant advantages over current methods, which all involve removing the surface coating or making direct contact with the steelwork of the survey area, whereas the EMAD is a rapid, non-invasive method that can scan through thick layers of tarmac, concrete or any non-ferrous material.

As it can be used on both wet and dry surfaces, where competitive equipment has proven to be unreliable, it can also be utilised in the oil, gas and petrochemical industries for pipeline

corrosion detection.

“Now huge, expensive structures can be surveyed accurately with minimal disruption and cost,” explains Rennison. “EMAD is a game changing proposition; it’s just that the rest of the world doesn’t know about it yet.”

So, to make the rest of the world aware Rennison set out in search of a design company that could create robust industrial units in which to house the high-tech probe and magnet technology.

Following weeks of research he had a shortlist of around six product design consultancies and eventually settled on 4D Products based in Cheshire.

“I selected 4D Products because I liked their creative philosophy and felt instantly at ease with the managing director James Bell,” comments Rennison.

Apart from Rennison’s wish to ruggedise the process, the brief was very open. “If you stifle a designer’s creativity by giving them too tight a parameter to work within then you are going to get what you think you want. But by giving them free rein, they will be able to invent something truly unique,” he says.

Housing the technology

Bell was excited by the challenge of creating a commercially successful product that was both functional and had aesthetic appeal.

“Of course it needed to be sturdy and easily transportable but, as these EMAD units will be very expensive, I was quite keen for them to look as though they are worth the money,” comments Bell.

“For me they had to look so much diff erent to anything else on the market otherwise there would be a natural assumption that they were just another version of the current technology.” Bell started off sketching his ideas and did initially wonder whether the EMAD had to be two separate devices.

“So, on the drawing board when we looked at all the parts that had to be made and all the various confi gurations, it actually ended up making more sense to have two separate units.

“The probe itself is very sensitive to metal so we couldn’t put metal within a certain radius of it. So we buried the probe deep inside the product to protect it with a ‘dead zone’ of non metallic items around it. We couldn’t have included the magnet in that unit too; it would have been too big and unwieldy,” comments Bell.

The horseshoe shape of the magnet was also unavoidable but rather than hiding it in a box, Bell decided to make a feature of it.

He spent a long time refining the design of the units creating up to eight CAD models before he was completely satisfied. “I would delete previous models because they just didn’t feel right. I was losing sleep trying to perfect it.

So, it was a great day when I called Bob and told him it was totally sorted,” he smiles. But it wasn’t just the body; other features underwent the same scrutiny.

For instance, the keyboard on the probe went through eight iterations and involved a great deal of back and forth work with the electronics supplier. Similarly, the wheels involved quite a lot of research too.

“The material on the wheels means that it doesn’t take on any water and keeps its dimensions for thousands of miles,” says Bell.

Challenging times

However, one of the biggest challenges during the development process was funding.

SciCorr was funded by six private investors but the budget was very tight. Bell’s solution to this was to make the two units as modular and cost effective as possible. “I worked hard to make sure that we could reproduce as many parts as we could.

For example, certain parts of the body can be used in both units, which means that we wouldn’t have to tool too many big parts,” he explains.

Also, the primary investor pulled out about ten days before the project launch (which was unrelated to the project itself). “We designed something for a budget and then half of it goes but we still managed to pull it off ,” comments Bell.

The reason why challenges like this could be efficiently dealt with was due to the good working relationship between 4D Products and SciCorr. “What I liked about working with 4D Products was that I wasn’t just handed a design at the end – I always felt like it was a partnership because I was involved the whole way through the process,” says Rennison.

4D Products also found a manufacturer to produce a prototype of the unit, which was in fact the first prototype that was ever produced and there was a lot of pressure for it to be right first time.

Amtech, a rapid prototyping company based in South Shields, produced the prototype using vacuum casting. “We use Amtech for all our prototyping work, they are excellent.

On the day Bob and I visited, they dedicated the entire company to us for free to assemble the units,” says Bell.

Although this part of the manufacturing process went smoothly, the handles were another issue. “We had to talk to 15 tube manufacturers before we could get someone to make two handles,” says Rennison.

“If you want 1,000 you can get them in China for next to nothing and they’ll look perfect but if you want just two – firstly, you are at the bottom of everybody’s list and secondly, you pay a fortune.

So, what we’ve ended up with for this first prototype are essentially handmade handles made of aluminium that have been painted in a chrome effect.”

Out in the field

Although Rennison and the team at Keele University are convinced EMAD is a game changing device, the challenge now is to convince those in the construction

and surveying industry that it is.

“The advantage of the EMAD technology over other methods is obvious but it’s proving that to the industry, and that is the stage we are at now,” says Rennison.

The new EMAD prototype was used for the first time in mid December at a site in Conwy, Wales. Adam Wootton, a researcher at Keele University who has been involved in the development of this EMAD technology for the past year, personally did the survey over two nights.

“The area had physically been checked beforehand and the surveyors knew where the problems were so they were delighted when our results matched theirs,” he says.

This was also the first time that Wootton used the new prototype on site having only ever used the proof of concept version. “I was amazed when I fi rst saw the new units – they’ve been realised perfectly,” he says.

“I’ve spent hours on site slaving with its predecessor, which was basically a probe on a stick and a big magnet on a heavy cart. It is obviously the same technology but in terms of what it looks like and how easy it is to use, it’s nothing like what went before.”

However, having successfully completed a few other surveys, including a steel footbridge and a multi-storey car park, there are a number of issues on the devices that have been noted such as incorrect cabling and buttons that would be better placed elsewhere.

“This isn’t a criticism – it’s part of the process, especially as this is the first prototype we’ve ever made,” says Rennison.

“I’ve started a development log looking at all the things that need to be put right. I wanted to have at least three months experience in the field first and then make the changes all in one hit.”

Planning ahead

The units will eventually be mass manufactured and sold globally.

Due to the positive feedback it has received so far and the significant potential of this technology, Rennison is now rethinking the SciCorr business plan.

“We are in that quandary of whether we sell the units or whether we lease them out and charge a day rate. But that’s for later, at the moment we are still at the stage of getting people excited about it by surveying ourselves,” he says.

In the meantime, Professor Haycock back at Keele University is working away on new concepts and iterations. “It’s a full cycle – we need to generate cash from this first product so that we can get the next product out of the professor’s head, onto paper, through design, into manufacture and onto site. And, once we’ve done that, it’s the next bit of kit.

That is how we want to fund and build the business,” explains Rennison. “And of course we will be using 4D Products again. There is no point going anywhere else having had such a good service.”

4D Products on aiding SciCorr in design of unique corrosion detecting device

Default