The Shannon Solo is the UK’s first production remote control, mini hi-tip dumper. From a distance of 100m the Solo can be operated to transport 500kg of materials travelling at a speed of up to eight miles per hour.

As the Shannon Solo is operated by remote control, it can be used in a variety of applications including hazardous areas such as quarries or demolition sites

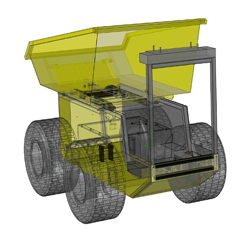

It was developed and manufactured by two entrepreneurs, Stuart Selway and Ryan Symes, over a period of three years. Although between them they have ample experience of the construction industry, they have virtually no design or engineering skills. However, through a process of trial and error they managed to create a final prototype of the Solo. It was only then that they had the 3D CAD model produced.

“We both had the same idea for the Shannon Solo dumper; we wanted to make something that was easy to maintain and simple to use,” explains Selway. “We are quite proud of ourselves because we are literally from the contracting and hire industry, we aren’t qualified engineers. But just through knowing what we wanted, we managed to get there.”

Selway and Symes established Shannon Plant Sales and Hire near Bristol in 1999. The business involved both selling and hiring out plant equipment. However, in June 2010 they sold the hire centre and renamed the company Shannon Plant (South West) Ltd.

The plan was to sell a range of plant equipment including its very own forthcoming Solo range. “When we sold the hire centre we then had the money and time to actually put the efforts into getting the Shannon Solo dumper finished,” says Selway. “For the past six months that is pretty much all we’ve done.”

Shannon Solo – Playing it safe

The inspiration for the remote controlled dumper came from Symes who had been doing contract work for the water authority close to deep water. Such areas are hazardous for operators due to the high number of health and safety risks involved. As a result, any plant equipment used has to meet very strict regulations.

So, the ‘eureka’ moment was when they came up with the idea for a dumper truck that could safely be operated in such hazardous work places. As well as deep water these could also include quarries, demolition sites as well as other areas that are considered dangerous for people to be in such as airports, power stations or railway sites.

“Everything about health and safety is about the operator. So when the operator isn’t on or near the machine in the danger area, there isn’t a problem. The risk assessment goes from pages down to a single sentence,” describes Selway.

Shannon Solo – Quality control

The brief they set themselves was pretty clear, essentially to make it as simple as possible to use and easy to maintain. They started off by attempting to make a toy remote control work with an existing mini dumper. “It never did,” laughs Selway. “Due to the frequencies the machine would go completely out of control, the levers would just break up and the connections, electrics and hydraulics just weren’t strong enough.”

Having soon realised that they wouldn’t get away with using cheap technology, they sourced their remote controls from Scanreco, a Swedish manufacturer whose products are widely used and comply with industry standards. Its digital remote control system is based on advanced microprocessor technology and, with its modular architecture, Symes and Selway could customise it to their specific requirements.

“It is a complicated system but basically it works by sending an electrical pulse from the portable remote control unit to open up the hydraulic valve in the dumper. This enables the operator to change the speed, direction and movement of the dumper,” explains Selway.

The Shannon Solo has been developed by two British entrepreneurs – Stuart Selway (left) and Ryan Symes (right)

They also realised that they could not use the original valve block from the small dumper. They needed to create one specifically for a machine that could run four hydraulic drive motors on biodegradable hydraulic oil.

Often hydraulics used in the construction industry can be quite jerky but through dedication, a lot of hard work, as well as consulting some local hydraulics engineers, they managed to achieve a very smooth control. This meant that the dumper was able to edge up to a skip very slowly as well as move quickly across an area at a speed of up to eight miles per hour.

Apart from consulting the hydraulics engineers, Symes and Selway did not utilise the skills of any designers or engineers during the development process. With ample workshop space and a 3.5 acre yard, they had the room to build and test various prototypes.

“We were moving on quite rapidly over the last six months; making something and if it didn’t work, breaking it up and starting again. We tended to know what we wanted so we just carried on ourselves,” says Selway.

“As we aren’t engineers we tried all different things ourselves. It was just trial and error really until we stumbled on the right sort of valve that would do the job. We bought lots of different ones to be honest. It worked in the end and it works very well now,” he adds.

Rising to the challenge

A number of challenges presented themselves during the development process. One of which was trying to make the dumper’s skip come down slowly if weighted instead of too quickly.

However, the biggest challenge, and one that required the most work, was figuring out how the Shannon Solo could smoothly travel up and down gradients of up to 25 degrees. When coming down a slope if the hydraulics were open the flow of the hydraulic oil would actually overtake the motor running. This would result in the Solo running away.

“The speed of the wheels going round was pushing the oil round faster than the motor so it would just open up and go,” describes Selway. “We tried the cheapest option which was to restrict the oil flow but that messed up all the rest of it. So we had to find some valves that would actually restrict the oil flow correctly at the right time to eliminate the roll away. We did eventually manage to achieve it.”

Keep on trucking

Whilst creating the Solo, Symes and Selway came up with additional uses for it. This led them to the idea of creating a range of mini remote control transporters under the Solo name. “Although it has a 16hp Vanguard engine, the chassis doesn’t need that amount of power to run.

But what we have done is kept ourselves an extra 7Kw of power spare (about 20 litres a minute) so that we can put auxiliary units onto the machine. We are calling it plug and play, so you can take one unit off and put another on,” says Selway.

In fact, they are in the process of developing a sprayer, which can be used to spray hazardous chemicals or simply water for dust control, as well as a rotary lawnmower, which would be ideal for airports or alongside motorways. “We can basically make anything as long as it can run off that sort of power,” he comments.

Shannon Solo – Safe as houses

Building the Shannon Solo involved a great deal of testing and, as the manufacturers, Symes and Selway also had to CE Mark it. This is a mandatory conformance mark that certifies that a product has met European Union consumer safety, health or environmental requirements. Additionally, the Solo had to meet health and safety requirements such as machinery safety directives, outdoor equipment noise directives as well as radio directives.

All of this testing costs money and together with the cost involved in protecting their intellectual property through registering their design, this project was no cheap endeavour. “It has been a lot more expensive than perhaps we initially thought it was going to be,” admits Selway. “However, we have been very lucky because the sale of the hire part of the business helped us with a bit of funding and we also have our own premises with plenty of room, which has been very helpful.”

Hitting reverse

With the final prototype complete, they now required the rapid production of full manufacturing drawings. These were needed to produce a production model of the Shannon Solo dumper for its launch at the Executive Hire Show in Coventry at the beginning of February 2011.

In order to reverse engineer the prototype Symes and Selway enlisted the help of local company Inspired Lines, which provides design, visualisation and CAD services within various engineering environments.

Nick Shadrick, the company’s director, felt that the best method would be to develop a full 3D model of the Solo and then create the technical 2D drawings from that. The reason being that this 3D model could then be utilised when Shannon came to develop its future bolt on products or if visualisations were ever needed.

“I spent two days in total at Shannon where I hand measured all elements of the existing Shannon Solo dumper and created a fully detailed 3D assembly while on site,” explains Shadrick. “As the design had been totally developed by hand at that stage we used the model to assess possible improvements, modifications and standardisations of parts and features.”

As the model was measured by hand, Shadrick had to virtually get inside the machine to measure the various components. However, with testing going on at the same time, they couldn’t strip it down completely to nut and bolt. “There was nothing so tricky that we needed to scan any parts because it’s very much based on standard framework to build a chassis and then plate forming to create the main body,” says Shadrick.

He built the 3D model exclusively in AutoCAD 2011. “Contrary to many opinions I have found the recent developments in 3D functionality of AutoCAD have made it a viable option for this type of project,” he argues. “I regularly use and lecture with various parametric modellers but have not written off the functionality of AutoCAD especially when dealing with one off projects that could vary from huge multi layered 2D/3D translations of environmental designs to quick mechanical component sketch ups.”

With the Executive Hire Show looming, the deadline was very tight but Shadrick managed to complete the manufacturing drawings within a couple of weeks. “The open minded, forward thinking approach of the guys at Shannon Plant allowed for the design and detailing to progress quickly and hit the tight deadlines required,” he comments.

Local support

Manufacturing and assembly of the Shannon Solo dumper is taking place onsite in Shannon’s vast workshop facilities. Initially, it will be made in batches of ten but if demand is higher this can be increased to batches of 20. “If we need to go bigger, we have the premises in place, it will just mean getting additional manpower. We are ready for whatever happens,” says Selway.

Next to launch is the Solo Sprayer, which can be used for watering golf courses, as well as spraying chemicals in hazardous areas

At the Executive Hire Show the Shannon Solo received many positive comments and feedback. “I must admit that everyone took on board what we have done. We had a number of companies that would like to buy the product and identified lots of different purposes for it. We are actually now developing a diesel engine for it through the feedback we got at the show,” says Selway.

With the dumper and sprayer launched and the lawnmower soon to be brought to market it’s shaping up to be an exciting future for Shannon. And although it has been hard work, Symes and Selway have enjoyed the process. “We have had great fun making it to be honest.

It’s a serious bit of kit but there is a fun side to it too,” says Selway. “Everybody that we have tested it on or has had a go at using it, you can just see the smiles on their faces. They pick it up straight away and they are also not scared of using it as they are nowhere near it.”

When you see the mini Solo dumper in action, it seems such an obvious solution and almost begs the question ‘why wasn’t it thought of before?’ “Maybe it’s so obvious that everyone missed it,” smiles Selway.

www.shannonplantsales.co.uk

Hands on development

In our age of computers and advanced CAD technologies it seems quite foreign to not utilise CAD from the beginning of a product development project. In most cases Inspired Lines, a Somerset based company providing design, visualisation and CAD services, is called upon by clients to be involved from the very start or early stages of development.

However, there are also times, like its work for Shannon Plant, where projects call for refinement of existing designs or simply bringing together elements of hand developed designs into a functioning digital model for evaluation.

“The Shannon project is an example of a small to medium sized company utilising in-house experience and hands on skills to problem solve and experiment on design ideas,” explains Inspired Lines’ managing director, Nick Shadrick. “I am convinced that utilising CAD software from the start would have helped massively with the development of this type of project but I also believe that depending solely on digital models from the outset would have stifled the creativity of personnel who have years of knowledge in physical design problem solving and prototype development.”

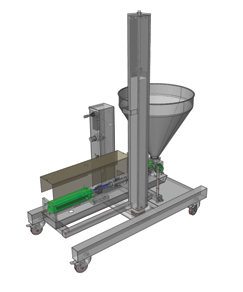

Development assembly for Brook Food Processing Equipment, a UK supplier of used and new bakery equipment

Another company Inspired Lines has been working with in a similar manner is Brook Food Processing Equipment, a UK supplier of used and new bakery equipment. The company’s development team uses its vast experience in hands on design and development to improve existing products and create new ones.

Inspired Lines is tasked with creating digital models and assemblies to bring together features and ideas for refinement, standardisation, visualisation, manufacturing documentation and digital testing if required. “Inspired Lines has been a breath of fresh air to us both the extremely fast turnaround times. This is something so important when trying to develop a new product,” explains Roger Staniforth, director of Brook Food Processing Equipment.

Shadrick believes that this combination of physical design development along with digital development creates a good balance and allows the creativity of all personnel to progress freely.

“Of course many companies are relying more and more on digital prototyping and design given the fantastic progress of the technology. Unfortunately this naturally phases out the vital experience in hands on development skills,” he comments.

“As a CAD user and lecturer over the last twenty years I have witnessed this trend but believe that there is a growing enthusiasm for the reintroduction of practical skills training that, when coupled with the CAD technology available, creates an ideal combination.”

www.inspiredlines.co.uk

The Shannon Solo mini dumper boldly goes where men fear to tread