Known locally as Mount Tam, Marin County’s Mount Tamalpais, nestled between San Francisco Bay and the Pacific Ocean, is a region of outstanding natural beauty. With over 160km of old fire roads and trails that criss-cross their way around the peak, it is also ideally suited to mountain biking and is considered to be the birthplace of the adrenalin-fuelled sport. During the 1970s early pioneers of the sport, including Gary Fisher and Charlie Kelly, were the first to freewheel down its trails testing out their inventions. Today, only a short ride away from the trails that lead to the summit, is Marin Bikes.

Marin Bikes was founded almost 25 years ago by Robert Buckley who stumbled upon a passion for mountain biking when his doctor suggested he take up cycling following a knee injury. Although the company has grown over the years, and gained a worldwide following for its quality custom-built frames, it still sticks to the convention of naming all of its mountain bikes after mountains, points of interest, towns and beaches in the county such as Sausalito, San Rafael, Kentfield, and Indian Fire Trail. “It’s quite funny that as soon as you cross the Golden Gate Bridge you begin to see the name of our bikes on all the road signs you drive past,” says Jason Faircloth, Marin’s product manager and bike designer.

All of Marin’s mountain bikes are named after mountains, points of interest, towns and beaches in Marin county

Faircloth, who is also passionate about mountain biking and has been riding bikes his entire life, came to Marin over five years ago from a bicycle component company. “Working at Marin turns a hobby into an income producing job,” he smiles. In fact, just about all of Marin’s employees are passionate about bikes. “When we have a spare minute of free time we don’t go out and play golf, we go out riding,” says Faircloth. “We are all riders and in our own ways are all pretty good.”

When a new bike arrives at the office from the manufacturer, everything stops. “We are crawling over each other to be the first to test it out,” says Faircloth. Indeed, when a brand new prototype was recently unveiled internally, as soon as the champagne was popped it was immediately wheeled out into the parking lot to be tested out by the employees. But this is not just to satisfy their passion for the sport. “We will try things out ourselves to make sure that they meet the design criteria,” adds Faircloth.

Driving development

With over 80 bikes in its range there is a huge cross section of designs and, with many new products introduced each year, innovation is essential in order to remain competitive. In recent times technology has become an even more critical tool in driving the company forward and three years ago Marin integrated 3D into its design and development processes.

“Although we had used AutoCAD for years to achieve superior design performance, we saw Inventor as the natural progression to stay ahead of the technology curve and keep making improvements to our bikes,” says Faircloth.

Jason Faircloth, product manager and bike designer, Marin

“Inventor allows us to produce cutting edge products by enabling us to get a lot more done in a lot less time. We design the basic platform of all of our bikes in Inventor and it allows us to really visualise what the bike will look like,” he adds.

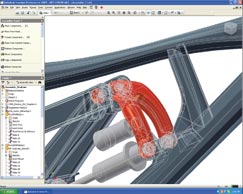

Faircloth admits that Inventor has completely changed the way he and his team design and develop bicycle frames as they are now solely designed in 3D. “We use Autodesk Inventor to design all the key elements of the bike – from the tube shapes to the frame technologies – in 3D,” he explains. By building a complete bike virtually on the computer they are able to check for interferences and overlaps. They can spin the 3D model around to test how it will react to stress on certain parts of the frame. “Inventor has allowed us to do things that simply weren’t possible before, whether it is complicated 3D shapes or complicated suspension designs where we have components interacting with each other, we have to make sure that clearances are maintained and tolerances are kept in check,” says Faircloth. As a result, a great deal of the engineering and strength testing can actually be done inside the computer now, which ultimately cuts down on the need to build physical prototypes.

The beauty of Autodesk Inventor is that it gives you expanded capabilities while still accommodating 2D

Form follows function

Engineering requirements are not the only side of the story because although many bikes are bought on how they perform, the importance of aesthetic appeal cannot be discounted. Marin bikes have a particular shape and style and although Inventor has allowed the company to completely update its range over the past three years, the signature style is still recognisable.

“One of the key aspects of 3D is that it lets us put a real premium on aesthetics,” comments Faircloth, who felt that for years, a lot of bikes on the market had a real industrial look with straight edges and square corners. However, it was important to him to start creating designs that took more of a cue from nature. “What 3D has allowed us to do is create shapes that are much more natural, flowing and organic,” he says. “These non-industrial shapes are incorporated into the frames, and the cross sections change in 3D as you move from one end of the tube to the other. That would be much more difficult to accomplish with just 2D.”

Downhill race prototype on show at the recent Sea Otter Classic, the biggest consumer tradeshow for cyclists in America

Although the design of the bike is carried out exclusively in Inventor, Marin still uses AutoCAD and both 2D and 3D work seamlessly together. “The beauty of Autodesk Inventor is that it gives you expanded capabilities while still accommodating 2D. Often, we’ll generate a 3D model of one of our frames, and then create a 2D drawing off of it to call out certain dimensions. This 2D drawing can be edited in AutoCAD, and then the changes reflected in Autodesk Inventor,” explains Faircloth.

Design inspiration

Inspiration for a new frame design can come from a number of sources. However, more often than not it is through feedback from the distributors, and of course the riding experiences of Marin’s own employees, that helps guide the design process. Customer feedback is also important and although most of this comes through the distributors, on occasion Marin’s team interacts directly with customers themselves – for instance, at the recent Sea Otter Classic, which was held from 16 to 19 April 2009 in Monterey, California, and is heralded as the biggest consumer tradeshow for cyclists in North America with over 50,000 visitors.

Once feedback has been gathered from distributors and users, initial ideas for a new design often start as a sketch on paper but very quickly move into a 2D drawing in AutoCAD or directly into a 3D model in Inventor.

Downhill racer

Using a downhill race prototype (which was shown at this year’s Sea Otter event) as an example, Faircloth explains the design process of a bike that would not have been possible without the use of Inventor. The bike features a Quad Link 2.0 suspension system, which has been engineered to handle the terrain better and transmit fewer vibrations to the rider, and because it is much more complex than traditional rigid frames, it was entirely designed inside Inventor. “This prototype is the third physical prototype version in three years and the seventh iteration in Inventor,” says Faircloth. “The reason why we decided to show it at the event even though it is still a prototype is because the next version will only be slightly different – it is mechanically sound and ready for production. It may just need some aesthetic changes made.”

This downhill bike started its life as a simple hand sketch drawing by Faircloth. With the suspension pivot position provided by ATB Sales, a UK developer of suspension technology, as essentially six X and Y co-ordinates, simple hand drawings were created before moving into 3D where pivots, tubes and linkages were all added to the frame and tested. “When you have this frame in Inventor you can start looking at collisions,” says Faircloth. “So, in about one week we can test the first prototype in Inventor.” The refinement of this initial prototype took quite a while because, as Faircloth explains, there are a number of things that have to be considered, not least of all ensuring that the new design stays true to the Marin brand. So, an internal group will then assess and scrutinise certain specific aspects of the design.

This downhill race prototype would not have been possible without Inventor due to the complexity of its suspension

Once the design parameters were defined and the detail worked out, the frame then underwent a series of computer simulation tests. Loads and stresses were applied, allowing Faircloth to tune the strength and performance characteristics. With this particular bike design they had to spend more time because of the Quad Link 2.0 suspension system. This system was originally designed for a 160mm design envelope but the travel on a downhill bike is 250mm so there is more wheel movement and as a result, Faircloth had to go through a number of revisions to get where he wanted to be. Once happy with the prototype, Inventor will then be used to make tooling, whether it’s for CNC machines or hydroforming. Concurrent to this, the refinement of the design also takes place.

The prototyping advantage

Although far fewer physical prototypes are made since the company started using Inventor, some still have to be produced. The frames have to meet strict international standards for strength, durability and safety, and every design has to be comprehensively tested, both in the laboratory and in the real world. However, where previously Marin would have produced up to six physical prototypes per bike, with the use of Inventor it now only requires one or two. Additionally, as Faircloth points out, as so much of what a bike is revolves around how it feels to ride, physical prototypes still have to be made.

“There isn’t any way to avoid doing prototypes because you won’t know how people interact with it if you only simulate it virtually,” explains Faircloth. “Until you build one up you don’t know how it feels.” Although they test the bikes internally themselves and have no qualms in hurling themselves off a side of a mountain to test out the design in the pilot run, Marin does use professional riders. The geometries are tested in this run and feedback from the professionals allows the team to tweak the design if necessary before it goes to production. For instance, only in January an award winning slopestyle rider – Andrew Taylor – was hired to test some of the bikes in the range as well as race them. This year he will be riding the Marin Wolf Ridge, Quake XLT and Alcatraz bikes in some of the biggest mountain bike events worldwide.

Once the pilot run has been confirmed then, as Faircloth puts it, they have the green light to go to production. The design is communicated effectively and without ambiguity to Marin’s suppliers and overseas manufacturing partners. They provide the manufacturers with all the dimensions in a 2D CAD file together with the 3D models so they leave nothing to interpretation or chance. By giving 3D models directly to their suppliers, they get fewer mistakes and more consistent results the first time round. “What you see on the screen is what you get,” he says. “Output is structurally and physically the same – there is no guesswork or filling in the blanks.” As Faircloth explains, the use of Inventor stops at this point in the development process. “We do not manufacture locally so we don’t make that translation from model to part here,” he says. “But the information that we are able to output from Inventor is 100 per cent reliable.”

Using Inventor has also decreased time to market. For instance, Marin has been able to cut the development timeline from roughly 18 months to just nine. But as Faircloth explains, the benefits of Inventor can be seen in two ways – it either cuts development time or allows them to do much more intricate design work and pay attention to a finer level of detail in order to bring new innovations to market. This year Marin has launched five significantly redesigned frames and 14 to 15 models of bike.

“Inventor has allowed us to make huge strides in product development. We have made changes and updates to our existing bikes while also creating wholly original, new models,” says Faircloth. “This would have been very difficult, if not impossible, to achieve without Inventor.”

RIVER DEEP, MOUNTAIN HIGH

Although Robert Buckley originally set up the company as Marin Mountain Bikes the ‘Mountain’ has since been removed to show that it now offers a comprehensive line of nearly 80 bikes for all skill levels and preferences in the mountain biking, road cycling, city and juvenile categories. Over the years the company has stacked up a number of technological advancements to its name including: Lightweight Hardtail Mountain Bikes, Performance Orientated Flat Bar Road Bikes meld, City and Urban Bikes. These bikes are distributed worldwide to over 45 countries.

Pioneering mountain bike manufacturer blazes a trail with Inventor