Taiga Motors is developing the world’s first production electric snowmobile that will be available later this year. Tanya Weaver talks to its co-founders about how the team went about designing it from the ground up

It seems fitting that the province of Quebec, Canada, where the average annual snowfall is around 100 inches, is where the snowmobile was first invented back in 1937. Created as an effective means of transportation in rural communities, its inventor was a mechanical engineer by the name of Joseph-Armand Bombardier.

A surname familiar to most as he went on to set up Bombardier, one of the world’s largest manufacturers of trains and airplanes.

Unlike other early snowmobiles that were being conceived at around the same time, his was commercially viable as it ran on caterpillar tracks making it suitable for all kinds of snow conditions.

Since then snowmobiles have come on drastically and are available in various sizes and specifications, but one thing they still all have in common is how noisy they are largely due to their combustion engines.

This seems incongruous to the natural areas they are often used in – to explore the backcountry or wilderness in ski resorts and state parks – where they shatter the silence and pollute the air. In fact, many areas in North America and Europe have restricted or even banned their use.

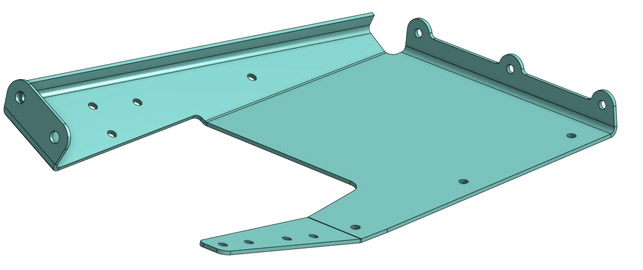

A sheetmetal part in Onshape. This sheetmetal utility was one of the new releases to Onshape that really attracted Taiga to the software

Taiga Motors – A world first

Enter Taiga Motors, which is also based in Quebec and similarly aims to develop a world first but, in its case, a zero emissions electric snowmobile.

“By using an electric powertrain we’re eliminating 75 per cent of that noise upfront,” describes Paul Achard, Taiga’s co-founder.

“You hear our snowmobile a little when it takes off, but once it gets roughly 100 feet away, you really can’t hear it anymore. It’s pretty much a stealth vehicle.”

Obviously it’s a huge tick on an environmental front but an electric powertrain does not mean compromising on performance or speed. “This is something Tesla has demonstrated and has finally been able to drive into public understanding that electric vehicles can deliver pretty astounding performance in acceleration.

“The characteristics of an electric powertrain mean that you can deliver instant feedback. And snowmobilers really look for top end speeds so we think that on a performance and environmental level, our snowmobile has the winning formula,” adds Achard.

Taiga Motors – How it all started

Although Taiga Motors was set up in 2015, the co-founders – Achard, Gabriel Bernatchez and Sam Bruneau – have been working on electric powertrains for over five years.

Studying for an engineering degree at McGill University in Montreal, they first met whilst participating in various student automotive design competitions, namely Formula SAE, Formula Electric and the Clean Snowmobile Challenge.

This really enabled them to gain hands on experience of what goes into building electric powertrains. For the Clean Snowmobile challenge, the team won the electric category in both 2013 and 2014.

“We received so much interest from those results that people were actually contacting us and asking where they could buy an electric snowmobile. We looked around but despite all the numerous electric cars and motorcycles on the market, we didn’t see anyone offering a production model of an electric snowmobile,” comments Achard.

With a clear market need and the experience of having built one under their belts, the trio decided upon graduation to launch a start-up company. Their aim was to design and build an electric snowmobile completely inhouse that could rival its combustion engine counterparts in terms of both speed and performance as well as with the added advantage of having better handling, less noise and no emissions.

The first area they focused on was the battery as it’s key to launching a successful product. “In electric vehicles, the battery system is usually the limiting factor so we knew we had to focus on that from the get go,” admits Achard.

“When that was in a good state we were able to shift our attention to the rest of the powertrain and all that is needed to optimise on a vehicle like this. But we took it step by step.”

Designing the vehicle from the ground up involved not just the electric powertrain but also going back to basics with the design and how to offer improved ergonomics and weight distribution. This resulted in them questioning every design aspect on the vehicle.

“With these small vehicles a lot of it is about the feel involved in operating them, which is why ergonomics and the weight distribution are super important,” explains Achard.

As the concept progressed, the business, with help from investors, also grew. The three co-founders were able to take on staff to complement their own talents in engineering but also those that could offer experience in design, marketing and business. Since launch, nine new members of staff have been added to the team.

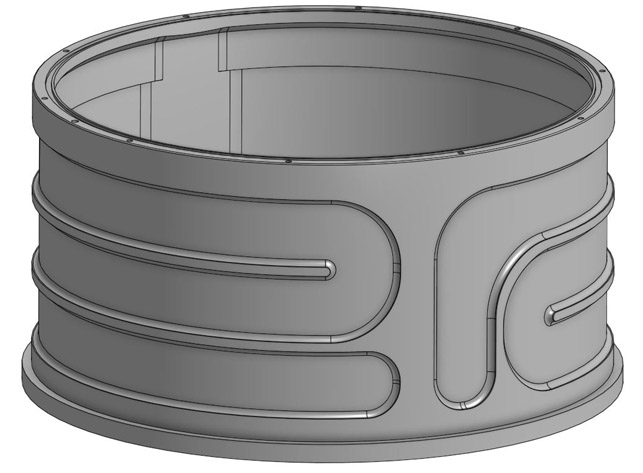

A machined part in Onshape

That part once produced

Taiga Motors – Getting onboard with Onshape

Up to a year ago, when Taiga Motors still consisted of just the three of them, they used one of the “conventional CAD systems” as well Altair for analysis work including mechanical, fluid, multi body and electromagnetic.

“We have also been trying out Simsolid, a meshless FEM [finite element method] software which is so fast it seems too good to be true, but our benchmarks so far have been on point,” says Achard. But with the inevitable growth in its IT requirements that came with a growing team as well as the need to effectively manage its CAD data, Taiga Motors started looking around for a solution.

Attracted to the idea of ‘cloud-CAD’ where CAD and design data management is carried out in a cloud workspace, it considered Onshape.

“Our initial impression was that it seemed good for hobbyists, especially as it’s not expensive, but not as a fully fledged competitor to what we were currently running,” confesses Achard.

But then, having kept track of its progress, this impression soon changed. “Within a couple of months Onshape had improved at an extraordinary pace. Just in that timeframe it had released sheetmetal utilities and seriously improved the surfacing tools.”

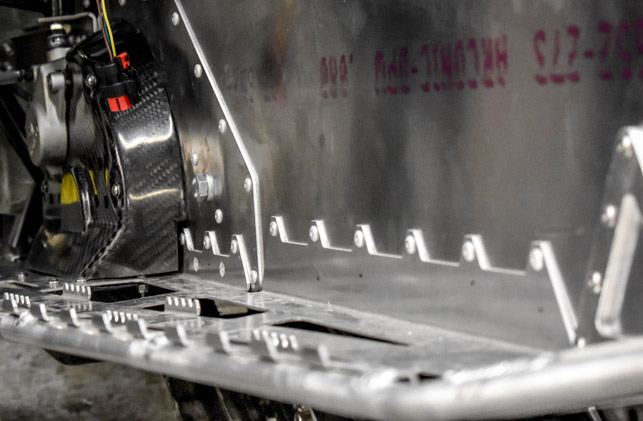

A sneak peek at the production model, due for launch later this year

A weldment part that was created in Altair using topology optimisation

Also, Onshape seemed a good fit not least of all because it allows the team to operate in a way that they think fitting to how a tech start-up should be operating today. “Like us, Onshape’s vision of what they’re offering has been developed from the ground up and we liked the idea of working with a company that’s really trying to do CAD the way it should be done in the year 2020, as opposed to how it was imagined in 1991 when I was born,” says Achard.

But, more than merely aligning to their own company ethos, when carrying out an inventory of what was needed from a CAD system Taiga Motors discovered that Onshape could fulfil 98 per cent of its needs. It also eliminated the requirement for a dedicated PDM solution or data vault.

“The way it manages your data is one of the best aspects.

It’s really like you don’t need to think at all about data management, which for us is great. Our IT needs are pretty much non existent,” claims Achard.

Another advantage of Onshape being cloud-based and running on multiple redundant servers, is that users never experience CAD crashes. And if a computer does happen to crash, the user can merely move to another, find what they were working on in the cloud workspace and pick up exactly where they left off.

“It was a bit of a leap of faith to switch to Onshape but one thing it has resulted in is a net decrease in screen punching incidents,” laughs Achard.

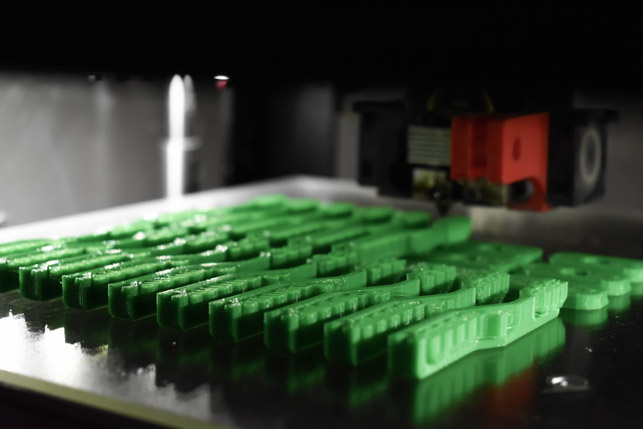

During the development process of its prototypes, Taiga has used 3D printing a great deal

Putting the alpha prototype through its paces

Put to the test

With its new CAD system in place, the team was hard at work creating the alpha prototype, which it completed totally in-house in time for testing by winter 2016. When asked what were the key challenges during the design process, Achard retorts, “A better question might be, which part of our design process has NOT been challenging!

“Jokes aside, I think we’re really proud of the packaging we’ve been able to achieve in our vehicle, which required months of collaboration within our team.”

The prototype was tested with professional riders, specifically those at Canadian Wilderness Adventures and Whistler Blackcomb, one of the largest ski resorts in North America. Ultimately, the testers were very impressed with one even commenting that it was so silent they couldn’t even believe it was turned on.

The feedback gained from testing was fed into the beta version, which the team has been working on over the past year. This prototype also incorporates a second generation powertrain and features Taiga’s own chassis system.

Following successful testing this past winter, Taiga Motors is due to unveil the production model of its first electric snowmobile in the next couple of months and plans to begin delivery to customers in 2019.

Featuring 120-horsepower, 100km range, 0-100km/h in under three seconds and weighing less than 500lbs, it will enable those who want to travel in and explore the great outdoors on a snowmobile to do so, for the first time, with a clear conscience.