Lush Cosmetics is taking advantage of the latest tools to bring more fun and relaxation to bathtime, as Al Dean reports

Lush Cosmetics is a company that requires little introduction. If you’ve ever set foot inside one of its 928 retail stores around the world, you’ll know that all five senses are in for a treat.

From massage bars and body butters to its legendary range of bath bombs, Lush’s products are an important part of bathtime in millions of households worldwide – especially at a time when many of us are prioritising self-care and relaxation.

Its championing of vegan ingredients, its ethical sourcing policies and its keen eye on reducing packaging, meanwhile, make for a guilt-free experience for even the most principled shopper.

For many years, Lush crafted the master moulds for its products by hand, using a mixture of clay modelling and stone-cast carving. This was often laborious and time consuming for the development team. Product iterations were less flexible, too, as each mould could take several days to create. What was needed was a heady infusion of digital and additive manufacturing technologies.

In 2018, Lush decided to enhance its product design capabilities and opened a state-of-the-art research and development facility at its headquarters. This is equipped with a range of design and additive manufacturing technologies and heading it up is innovation lab manager Damien Carter.

Carter’s route to managing Lush’s innovation lab is not the traditional pathway you might expect. Prior to joining Lush, he was making furniture in his native Poole, before joining Lush as a technician in the moulding department in 2014.

As he explains: “I didn’t have any experience in what I do now. I joined Lush in the bubble department, working on various machines, pressing the products. I then went into work in the mould-making department, making all clay models and moulds by hand. We were pouring things in epoxy resin and then using a Dremel to carve out the detail. I did that for about a year.”

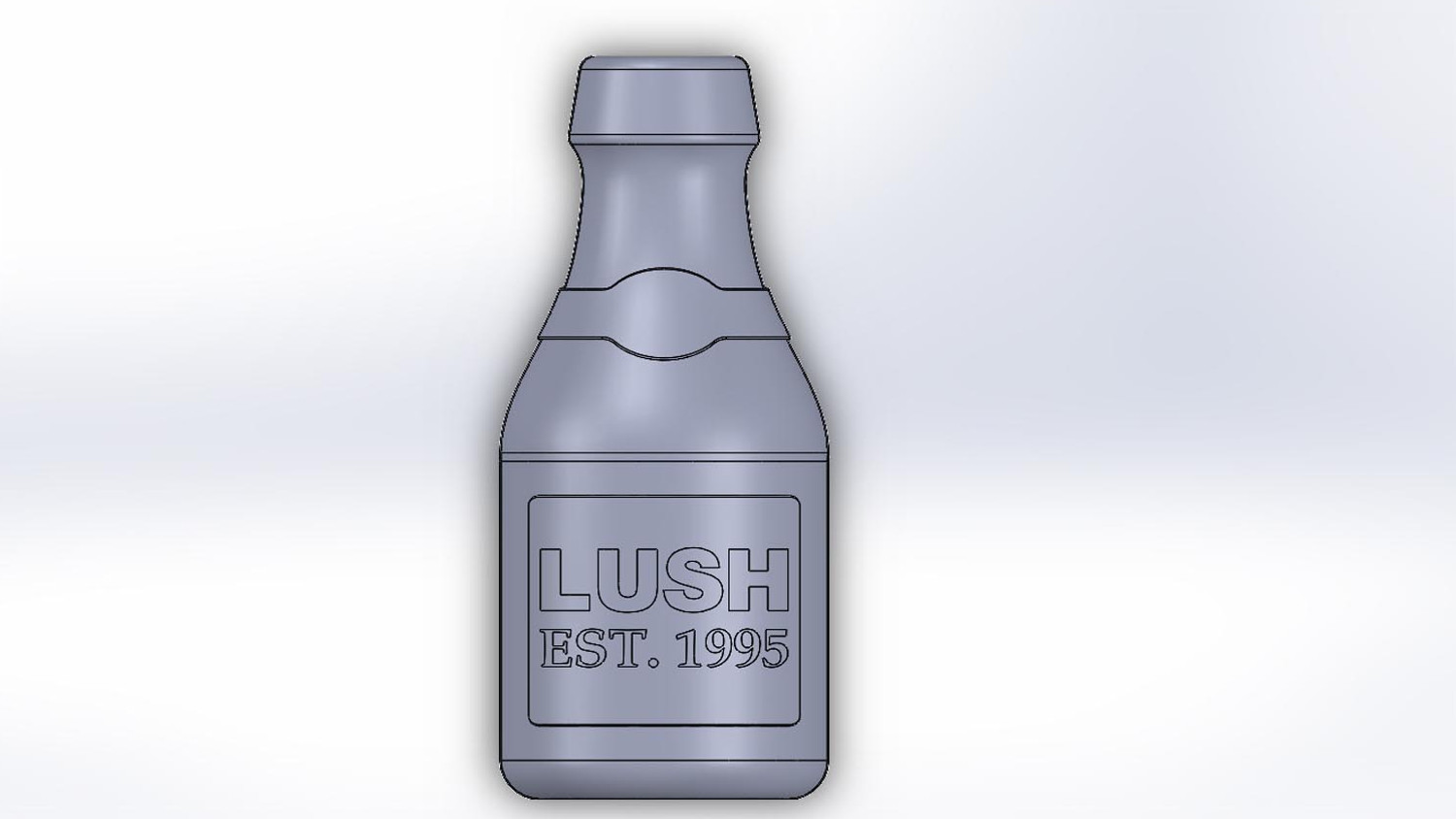

Lush then started to look into 3D printers, he says, “because we always struggled with complex designs, particularly with lettering. We were cutting letters out of cardboard and then putting them on a block of wood then making a mould of that, pouring it and then having to Dremel and drill it. It was quite a long process.”

Lush first investigated 3D printing seriously in 2016, creating a couple of samples. It went really well, according to Carter. Today, the innovation lab has six Formlabs Form 2 printers, three Form 3s and a largeformat FDM printer. That’s on top of its own laser engraver and a brand-new CNC mill.

“The reason we’ve stuck with Formlabs printers is usability and reliability. We just plug them in and can expect to get great results every time. The 3D renders also help our colleagues visualise the intricate details of the product before sending the designs to production. There’s all sorts of stuff going on now,” he says.

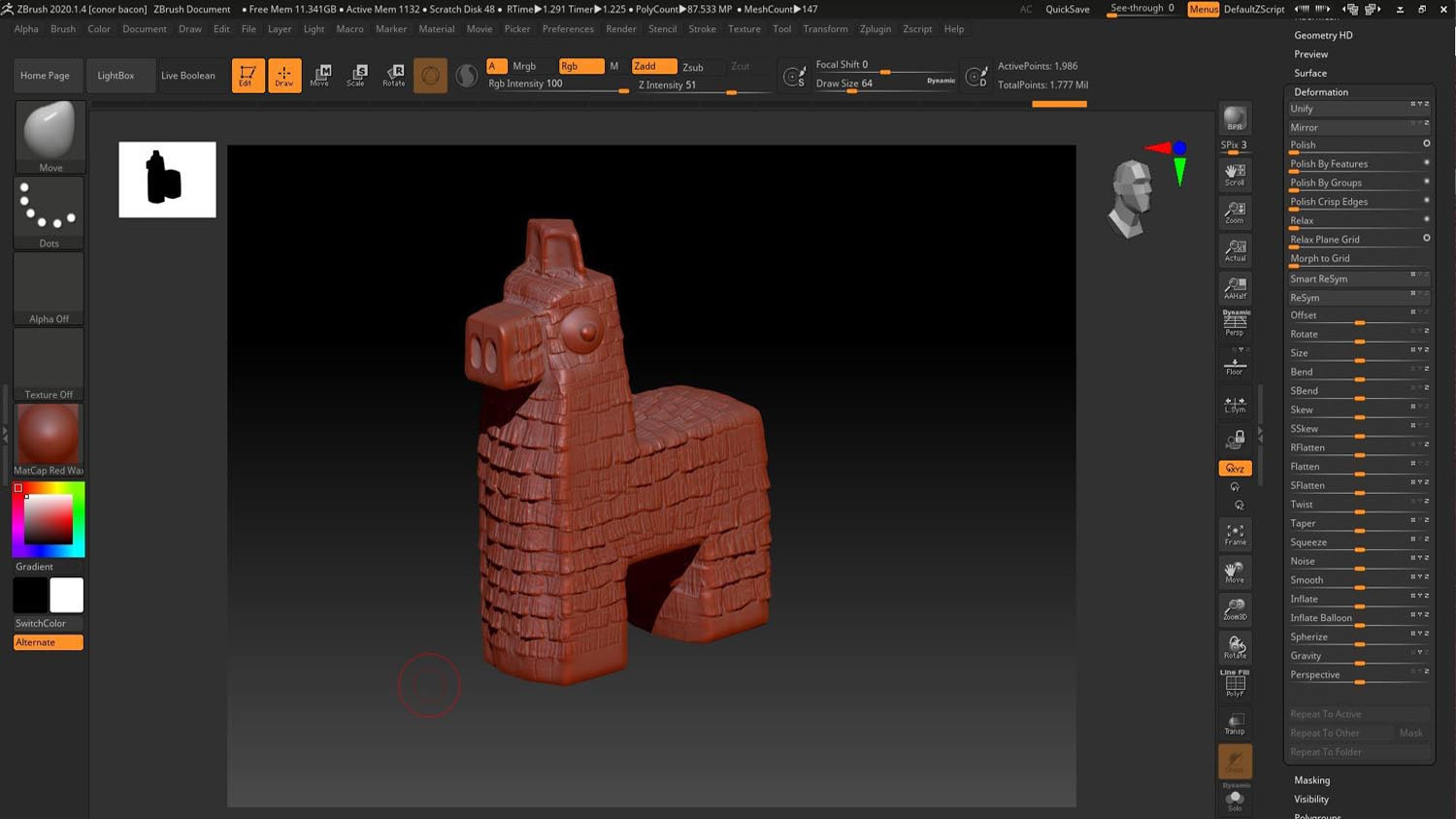

Alongside the adoption of additive manufacturing technologies, this period also saw the innovation lab build up its workflow to drive those machines and select its digital design tools, eventually settling on a combination of Solidworks and ZBrush.

As Carter explains, a former colleague from France was already experienced in Solidworks, having been taught it at school, and showed him the ropes. Along with a natural affinity for more complex software (his passions outside of work include music production), Carter found Solidworks to be a good fit for the type of work Lush needed to do.

While 80% to 90% of Lush’s design work is now completed using Solidworks, Carter’s team also uses ZBrush for more organic modelling. Often, a combination of the two is used to achieve the final forms. “Sometimes, I model something in Solidworks and then put it into ZBrush, just to sort of smooth it off or change it more organically,” Carter says. “ZBrush is much better for that organic shape.”

Lush – Progress to production

Once digital designs are ready, Carter and his team will prepare prototype moulds and carry out small-scale batch tests to ensure that a design is manufacturable using Lush’s processes. A new set of masters is then provided to the in-house moulding department, which will use its own vacuum formers to test the designs in a large batch.

When production readiness is achieved, tooling is built for production, via either a combination of vacuum forming and epoxy resin or, more recently, aluminium tooling, also in-house.

Once tooling is ready, it’s sent out to each of the departments and manufacturing sites, depending on the product: Ballistics for bath bombs; Bubbles for bubble bars (crumbled to create a bubble bath); and Massage for massage bars. Carter’s team also makes interesting use of laser scanning technology, primarily for scanning existing casts, which can then be reproduced or edited for size and reused. Here, it relies on a Creaform Go!Scan 3D.

“Sometimes we get asked to scale up existing products, so this is ideal,” says Carter. “We also use it to scan in objects and manipulate the data to make the said object mouldable. We were asked to make a local artist’s wood resin sculpture into a bath bomb mould. To do this, we scanned the sculpture, manipulated the data – that is, we removed any undercuts so the product would release from the mould – resized it, then printed it.”

Australian bushfire relief project

Another example of how 3D printing has enabled Lush to stay reactive was its ‘All The Wild Things’ relief project in 2020. In January of that year, the company began selling koala-shaped soaps to raise money for the Bush Animal Fund, a charity helping wildlife in the wake of the Australian bushfires. The soaps were limited-edition: 50,000 were available worldwide, to represent the number of koalas in Australia. They quickly sold out and fans begged the company to make more.

Carter was extremely proud to be part of the team that worked on this project, he says. “We were able to turn around the mould designs within 24 hours with Formlabs printers and the custom Koala soaps went into production in under a week.”

Lush – Plans for the future

Lush likes to think of itself as a business that’s fast to react to changing circumstances and trends.

“Things change daily and I stopped planning my days down, because there are different priorities that come from various places. It’s very much a case of, ‘Come in and see what happens.’ In the future, we’d like to expand the team, but in the current climate, that’s difficult and it all comes down from workload,” says Carter.

One thing he definitely wants to do is to equip other manufacturing sites around the world with their own 3D printers and CNC machines.

“Then I can email them files, and they can print them off there. It’s just a lot quicker when we don’t have to send it in the post. When we release a new product, we have to get the mould master to them. At the minute, they’re getting pulled in epoxy resin and sent.”

Carter’s goal to build better connections between Lush’s manufacturing sites across the UK, Japan, Australia, Croatia and Germany using 3D printers as the conduit is an interesting one.

In fact, it’s how he works already with the Lush team in Japan, the first overseas manufacturing unit to have its own 3D printers. When new designs are created, masters for moulding can be sent out straight away, and Japanese colleagues can print them the next day. It’s faster, more environmentally friendly and easier on the company’s budget and product-release schedules.

Where once mould creation took two to three days, the average design now takes just 4.5 hours to print. As a result, the team can take ideas from design to manufacture in under 24 hours. And that’s all the better for customers desperate for a little self-care and indulgence in these stressful times.

Thinking outside the box

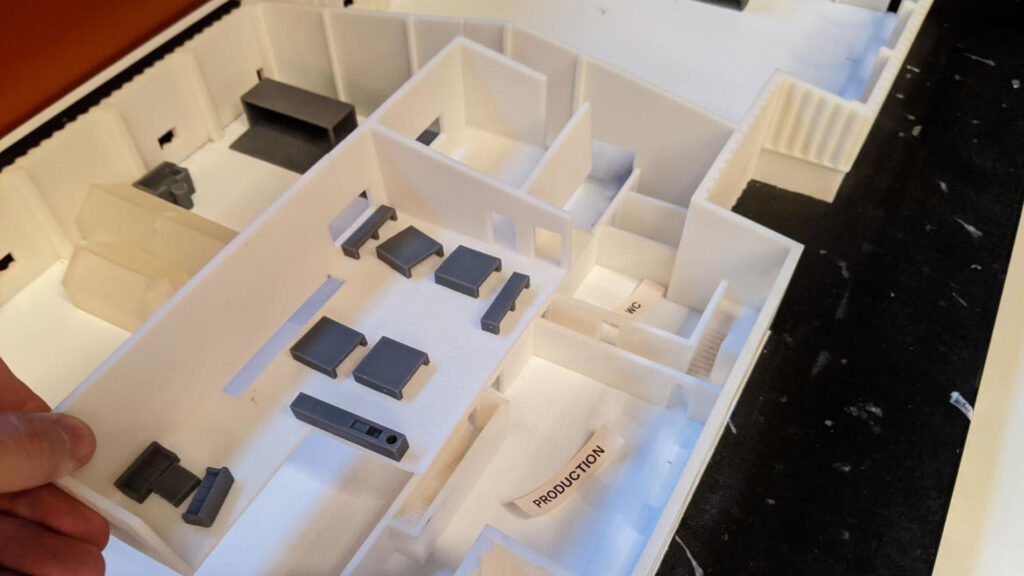

Lush’s new additive manufacturing unit is a tribute to the very technology that it is designed to house.

Engineers wanted to be able to fully visualise the building and create a scaled architectural model, in order to make the best use of the large open space.

For the work involved, the company received a quotation for £15,000, including labour, materials and shipping, from a specialist architectural design bureau.

Instead, Carter took matters into his own hands, building a mock-up of the space in Solidworks and then printing it on a Form 2 3D printer, using a mix of standard engineering materials from Formlabs.

He calculates the costs associated with this in-house approach at around £900. And in addition to savings of over £14,000, the project was delivered faster, too.

“We found this to be a great tool in terms of spatial planning, which means we can 3D print our equipment and then we can tangibly look and feel how something is likely to fit within units,” he says.