The man credited with drastically lowering coal miner fatalities was British chemist Humphry Davy (1778 – 1829). In the early 1800s explosions in coal mines, particularly in North East England, were rife due to the open flame from the miner’s lamp coming into contact with pockets of methane gas often found as the miners dug deeper.

In 1815 Davy invented what became known as the Davy Safety Lamp in the basement laboratory of the Royal Institution (Ri) in London. This simple lamp design featured a wire gauze chimney enclosing the flame. The holes allow light to pass through but the gauze metal absorbs the heat and prevents an explosion as the flame is not sufficient to heat the flammable gas.

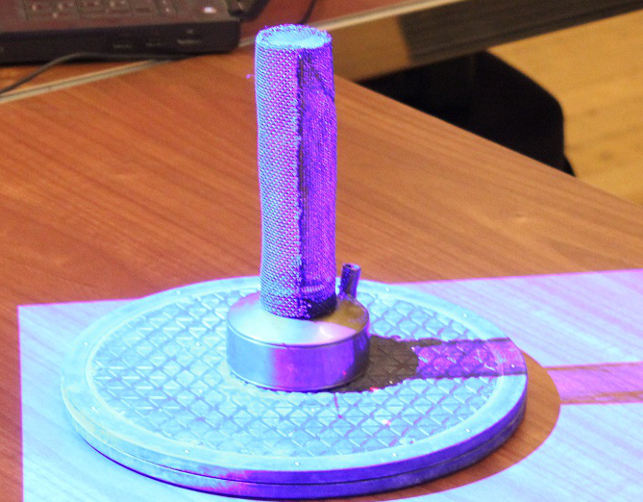

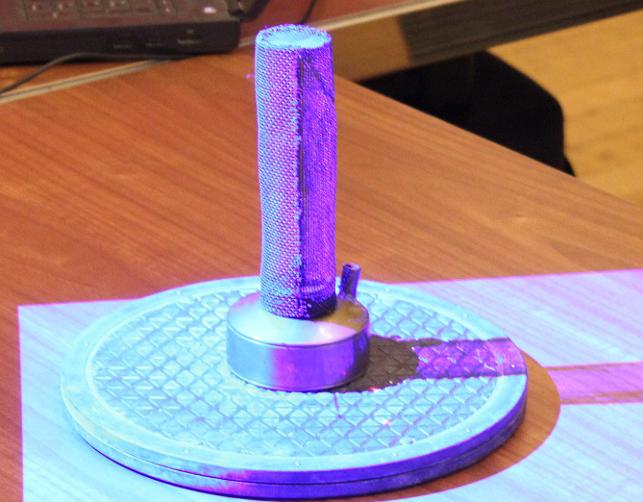

Physical Digital 3D scanning the prototype Davy safety lamp to gain highly accurate measurements in order to produce a 3D model of the lamp through reverse engineering

The Ri (where Davy was actually a Professor of Chemistry) has a prototype of the Davy safety lamp on display within the Faraday Museum in London. In a bid to extend the accessibility of museum exhibits to a larger audience Ri worked on creating a Magic Box exhibition facility.

At first sight this appears to be a traditional display cabinet but has a touch screen that enables visitors to view a 3D model of each historical artefact together with its supporting material such as drawings, reference books, diaries or research papers.

3D scanning the lamp

Physical Digital was called upon to create the 3D models of some of these historical artefacts such as the Davy safety lamp.

In strictly-controlled conditions at the Ri, the lamp was placed on a measuring table on which had been placed a number of markers.

Images were captured using Physical Digital’s GOM Triple Scan system of the markers and lamp, within a cuboid sized 320mm x 240mm x 200 mm. The resolution of the 3D scanning was 64 microns, which means that the minimum distance between any captured points was 0.064mm, resulting in a very high resolution image.

Once the data was captured within the GOM scanning systems, it was processed by Physical Digital’s design engineers and through the technique of reverse engineering a CAD model was gradually and carefully built up to replicate the historic artefact.

Surfaces were created using vertical and horizontal cross-sections through the scan data. The 3D curves were then created through intersections at equal intervals after measuring the mesh structure from the scan data, then weaved splines to resemble the original model.

The final CAD model is a combination of free form CAD for the gauze chimney and parametric solids at the base of the lamp.

The Royal Institution has a prototype of the Davy safety lamp on display within the Faraday Museum in London (image courtesy of Paul Wilkinson)

Other items captured

As well as the prototype Davy Lamp, Physical Digital’s 3D scanning engineers also captured the data from the Tsar’s Cup, a silver-gilt cup, which Davy received in 1825 from Tsar Alexander I of Russia in recognition of his invention of the miners’ safety lamp a decade before.

Other items that were captured include Faraday’s Induction Ring and the world’s first electric generator, which were both invented by Michael Faraday, a British Scientist and Fullerian Professor of Chemistry at the Ri who was actually taken on by Davy as his assistant whilst touring the continent between 1813 and 1815.

Physical Digital 3D preserves a piece of Industrial Revolution heritage – the Davy Lamp

Default