Jetson One, the single-person electric VTOL which aims to democratise and decarbonise the aircraft industry, is set to be produced by the end of 2023

During the course of the last century, the arrival of flying cars has gone from being strictly part of sci-fi imagination to being perceived as an actual possibility, and has been mistakenly foretold countless times.

For the generation who grew up watching Back to the Future and was expecting the new millennium to come with a new, revolutionary way of commuting and travelling, it can be disappointing that, in 2022, we still have to rely on cars and and traditional means of transport. But this disappointment might not be for much longer.

Jetson is a personal aircraft company that aims to democratise flights, by removing the huge boundary between being able to drive a car and being able to fly an aeroplane.

“Right now you look at the car and you instantly know: oh yes, I can drive that,” says Jetson head of R&D Alec Bialek. “We want people to feel the same when they look at an aeroplane.”

The story of Jetson’s establishment started with Tomasz Patan and Peter Ternström and their shared passions for helicopters, and aeroplanes.

Together they started developing the idea of building a flying vehicle so lightweight that it doesn’t need to pass all of the certification requirements that are normally necessary for full-on aeroplanes and that is accessible and easy to fly.

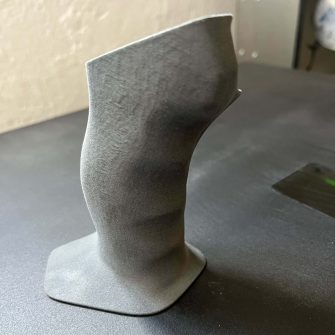

To achieve the first goal, the two co-founders knew that the best manufacturing method for certain parts of the aircraft was 3D printing, as it allows the production of hollow structures and very narrow lattice patterns while having strong and sturdy parts.

Moreover, in the case of unique components, casting or moulding would have been too expensive and, until the demand for Jetson One will be high enough, 3D printing is the most convenient alternative to serial production.

As for most product design workflows, AM is also used for prototyping: “We are using the printers for making prototypes, as we are trying different things. It is also nice to model something in CAD software, print it, and physically hold it in your hand and put it on the vehicle. It is how you can see if you like it as this thing works,” says Bialek.

“When 3d printing is so cheap, so accessible and so quick, it is actually a really great tool to sanity check your own designs,” he adds.

Jetson has selected SLS (selective laser sintering) as its technology of choice, because of the high quality of printed parts, the good accuracy and strength, and because, unlike FDM or SLA, it doesn’t require supporting structures.

“The print quality is much better than with FDM. As Jetson One is a premium vehicle, we do care about the quality of the parts coming out and the quality associated with SLS is unrivalled. The material properties are better when compared with FDM, and there isn’t a need for support material. That is a big advantage when we try to heavily lightweight our structures,” says Bialek.

Being SLS a notoriously expensive technology, the Jetson team was after an affordable option which they found in the polish 3D printers manufacturer Sinterit.

“As John C. Maxwell once said,” quotes Bialek, “fail early, fail often, but always fail forward. You want to try things. You don’t want to have only one shot. You want to see what works, what didn’t work, and the quicker you can do those loops, the faster you can develop.”

The company’s first acquisition was Sinterit Lisa SLS 3D printer. In recent years, the Sinterit line has grown, and now features two more devices: Lisa Pro, and Lisa X.

Bialy, who joined the company around the time Jetson purchased Lisa X, remembers the transition from Lisa Pro to Lisa X as being smooth and easy, with the advantage of a larger print volume and a higher speed, offered by the latter.

“When we look at Lisa’s line of printers, or Sinterit in general compared to other companies, the two major things that we liked were the materials, that are open source, so we are not locked into one brand, the materials that may have supply chain issues or just very high pricing because of some unique material. We are able to look around the market and use a material that works best for the part.”

“Another thing was how good the customer service has been. We were quite happy with all the support we received for Lisa Pro. When we were looking for a bigger printer we had a good experience, with no complaints, so it was a very painless upgrade for us for Lisa X,” adds Bialek.

Jetson engineers use Lisa X to print brackets that hold motor speed controllers and the inverters, the bezel trim for the instrument cluster is 3d printed, and the radar, as well as the GPS antenna, are also made with AM. Assembling Jetson One requires test templates that are also 3D printed.

AM helped the Jetson design and engineering team to speed up times to market, with delivery now planned for the end of 2023, and take the aircraft industry a step closer to the future we’ve been imagining.