Some of the mainstream vendors have started to integrate Life Cycle Assessment tools (LCA) into their toolkits. This enables the user to evaluate the environmental impact of a design during the development process.

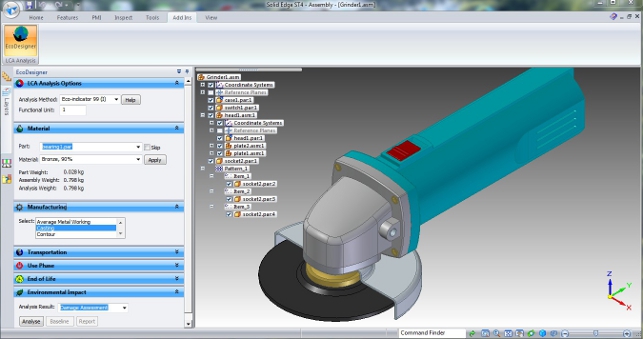

A LCA analysis being carried out on a grinder assembly in Solid Edge ST4

Autodesk is perhaps the leading example, with its Eco Materials Adviser introduced into Inventor 2012. But there are now a number of third party developers working to build similarly CAD-integrated capabilities for other tools.

One such developer is US-based Trayak, who has introduced its EcoDesigner system for Solid Edge, first in ST3 and now in ST4.

EcoDesigner is found in the navigation bar under add-ins. On install, it supplements the existing Solid Edge materials library with the LCA data required for each entry.

The system automatically picks up the assigned material, weight and volume of all the parts in the assembly. The user can then experiment with different materials by reassigning material from within EcoDesigner.

The process used to manufacture each part is selected from a list such as cast, machined, injection moulded, sheet rolled and so on.

At this point, it’s possible to conduct a first pass analysis. But, if the additional information is available to hand, it can be added in. For instance, transportation methods (including plane, boat, truck and rail) can be mixed with approximate distances so a realistic value can be achieved.

Use phase allows input of both useful life (in terms of years) and annual energy consumption. The final is end of life treatment.

Unlike other LCA systems, EcoDesigner allows for the specification of percentage recycled content by assembly weight.

This enables the user to understand the beneficial impact of designing for recycling because credits can be gained for reducing the use of virgin material.

Data sources & Assessment methods

The world of LCA differs from the world of mechanical properties and simulation.

This can be confusing for a designer or engineer who is used to working with explicit and well defined data for materials properties.

In the LCA process there are two key components to be aware of. They are:

Database sources: This gives the values for environmental impact for each material, associated manufacturing processes, energy, transportation and such.

The range of databases is differentiated by various collection methods with different focuses. It is important to use peer reviewed databases (like EcoInvent) that provide transparent documentation regarding their collection methods.

Assessment methods: Alongside the database source, there are a number of different methods of taking that source data and calculating the environmental impact of a product.

Again, these vary geographically and in their focus. Now, here’s where it gets interesting.

While high-end and standalone LCA tools will allow an organisation to select the database and method used for each analysis, designer- or engineer-focussed tools typically do not.

To make the use model more simple, this class of tool tends to rely on a single database and method for impact assessment. This is where EcoDesigner differs.

EcoDesigner allows the user to select the most appropriate method and data.

For users working on a first life cycle assessment, or those conducting screening level assessments, this may not be a huge

issue.

But for those with more experience or perhaps with specialists within their organisation conducting full LCAs, this initial data can be used for further work downstream or indeed, concurrently between designer and LCA expert.

EcoDesigner also allows the user to extend the material and process data allowing them to use any environmental data that may have been collected for proprietary materials or manufacturing processes.

Results & Interpretation

With the results presentation method, an assembly can be viewed as a whole in terms of its environmental impact.

This can then be broken down and inspected in a couple of different ways.

EcoDesigner allows the user to perform quick analyses on either an existing product or a new project and establish that data from the word go — whether it be a clean sheet project, an iteration or redesign of an existing product

If the user is focussing on specific impacts as defined at a corporate level, carbon footprint or water use would be of most interest to them.

Each can be broken out, obviously depending on the method and data used.

The user can then split these out per part, making it clear where the heavy impacts are coming from.

There are also base lining tools which allow a starting design or legacy product to be used as the basis for comparison during a redesign process.

In terms of formalised reporting tools, EcoDesigner outputs HTMLbased formats and these can be repurposed into Word docs or PDFs.

Conclusion

We’re all aware of the drive to reduce the environmental impact of the products we develop but it’s often the case that the efforts are confused by complexity factors and commercial pressures.

What’s required at the very start is the ability to establish the impacts of the products we have and those we are developing for the future.

The integration of LCA into the design process can greatly assist with bringing this previously nebulous data to hand and allow the team to make judgement calls on where effort should be placed.

A system such as EcoDesigner allows the user to perform quick analyses on either an existing product or a new project and establish that data from the word go — whether it be a clean sheet project, an iteration or redesign of an existing product.

This means that design decisions can then be evaluated, not only in terms of function and performance using traditional simulation tools, but data can be collected about material choices and other factors that influence environmental impact.

Trayak has done an excellent job with EcoDesigner for a fi rst release. The fact that it’s all tightly integrated into Solid Edge’s interface and pulls data from the host system is good solid stuff. I can’t wait to see what the company comes up with next.

| Product | EcoDesigner |

|---|---|

| Company name | Trayak |

| Price | Both license and subscription model available |