For over 50 years, Austrian motorcycle manufacturer KTM has held a reputation for producing motorcycles that embody the company philosophy of ‘Ready to Race’.

Recently, it has dipped a toe into the automotive market with the launch of the KTM X-Bow (pronounced ‘cross bow’), a high-performance racing car that recreates the exhilaration of riding a motorcycle on four wheels. With its aggressive styling, this two-seater sports car boasts a 177kW Audi TFSI turbo-charged engine that powers the 790kg lightweight to 100km/h in just 3.9 seconds.

The KTM X-Bow boasts a 177kW Audi TFSI turbo charged engine in a vehicle weighing just 790kg

Stefan Pierer, KTM’s CEO, believes in the benefits design can bring to the brand and has worked closely with Kiska, Austria’s largest design company with over 100 employees, for the past 15 years on the design of all its motorcycles as well as the company’s overall identity.

“Stefan Pierer and I were sat having a beer back in summer 2005 and put one and one together,” remembers founder and MD Gerald Kiska. “Fewer and fewer young people were applying for a motorcycle licence, so it was a foregone conclusion that our customer base was shrinking. We thought about quad bikes, for which you don’t need a motorcycle licence, but the vehicle concept transpired to be unsuitable – not safe enough on asphalt. The next logical thought was what would work on the road and attract the attention of people with a driving licence for cars? A car, a racing car.”

Risk and reward

Kiska’s transportation designers were called upon to help KTM make this potentially risky transition, bringing its core values of performance, purity and adventure to a new market. But before pen was put to paper, Kiska carried out extensive research and analysis, dictated by its Integrated Design Development (IDD) process.

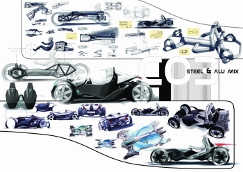

Photoshop and Wacom CIntiq tablets were used produce concepts and design themes

During IDD all relevant aspects of the brand are taken into account: from analysis of the market and strategy development through to conceptual and product design. This is followed by marketing and communication strategies together with the design of the product environment (such as POS, shop and exhibition design). Kiska’s strategy, transportation design, product design, communication design and environmental design departments complete the process under one roof. In the case of the X-Bow project, a thorough target group analysis was initially carried out to ensure that they were creating the best possible output for the target groups.

From here, Sebastien Stassin, Kiska’s head of transportation design, and his team kicked off the design development process by sketching a few rough ideas on paper. Apart from specified legal mechanical and aerodynamic guidelines, the designers were given carte blanche. The intention was to create a street-homologated car with ‘transparent’ technology, in which every part fulfils a specific function, packaged in a simple, minimal design.

“The aim was the simplicity and performance of a motorcycle, with exposed mechanics and no filter between occupants and experience,” says Stassin. “The car has no roof, no windshield and no heater. It has the acceleration of a motorcycle with the road holding of a race car.”

Substance before style

But this was not merely an exercise in styling. To turn the X-Bow into a racing would require some advanced technologies. “This was and continues to be a dream project. The purity of the direction and the requirement for race car performance tests us to truly design the vehicle, not simply style it,” confirms Stassin.

In order to do this, Kiska and KTM discussed various materials and construction methods before deciding on the best partners to assist in the design process. As they ambitiously wanted the X-Bow to feature a carbon fibre monocoque (reserved for Formula 1 cars) they called upon Italian racing and sports car expert Dallara. “Carbon fibre is extremely lightweight for its strength and does not fatigue over time,” says Stassin. “Dallara has over 20 years of experience in the field and has developed many proprietary finite element analysis tools for carbon structures.” As well as developing the monocoque, Dallara provided chassis, aerodynamics and suspension development.

Traditional sketching skills were used alongside digital media for concepts

In May 2006, having secured an Audi engine and Dallara’s support, the designers sketched the chosen design direction into their Wacom tablets – a tool that allows them to immediately visualise their thoughts with a patented pen technology on a high-resolution LCD monitor. To achieve the unique overall shape, the design team then moved into Alias for advanced surface modelling, with further CAD work carried out in Pro/Engineer.

The X-Bow design is a construct of various technical components – a direct influence from KTM motorcycles – chosen for their functionality and performance. “We interlinked the technical components with ‘floating panels’. These ensure perfect aerodynamics and road holding, and can be further developed individually,” explains Stassin. These four simple body panels, in KTM’s corporate orange, also serve an aesthetic purpose, complementing the simple headlamps, embedded indicators, which are flush with the car’s contours, and round lights at the rear.

Kiska has rapid prototyping machines in-house, and a facility to build models. “We build clay models of all our vehicles and test them extensively. We scan them and create and modify the data as it is shared with our suppliers,” says Stassin. “The best feature of all these tools is the ability to evolve the vehicle using the results of the analysis we received from FEA, CFD and wind tunnel sessions.”

Put to the test

While the KTM development team covered more than 100,000km with the test vehicle and early X-Bow prototypes, Dallara carried out over 200 tests in the wind tunnel – the equivalent of 100 testing hours and 29 complete car CFD runs. Tests on bodywork in the wind tunnel were conducted at speeds of around 130km/h, to ensure efficient aerodynamic performance.

Clay prototypes were used to refine the forms

According to Gerald Kiska, a high point of the project was the success experienced in the aerodynamic development of the car. “Generally aerodynamic specialists are not prepared to make any compromises; usually the design of the car is inferior to aerodynamics. As a certain level of performance is expected from the X-Bow, the aerodynamics were given top priority. We then proceeded to further enhance the aerodynamic specification with our ideas and designs in many tests, sometimes to the amazement of aerodynamic experts at Dallara.”

To complement its own in-house design team, which grew from two designers to five during the project, there were over 30 specialists from the fields of model construction, engineering, aerodynamics, mechanics and testing involved in the development of the X-Bow. “KTM did not have an automotive division to collaborate with. All of the expertise was derived from our work group including Kiska, Dallara, Audi and IAV [a provider of engineering services to the automotive industry],” says Stassin. “The project was exhilarating, and a great opportunity for everyone involved.”

Best in show

After an 18-month design and development phase, the prototype was unveiled at the 2007 Geneva Motor Show on a stand created by Kiska’s environmental designers. The aim was to test public opinion to this aggressively designed sports car. “At first, we said that we would present a model of our car at the motor show and see how it went,” says Gerald Kiska. “We had prepared some pro forma sales contracts which only said ‘I undertake to buy a car at a price to be notified at a later stage’. The car stood there and we sold 70 units within the first three or four hours.”

Following this success, they realised that they would have to commit to building more than just the limited edition 100 originally planned. So, after more development and testing, Kiska and KTM were back at the 2008 Geneva Motor Show to present the production-ready X-Bow. “Normally, a show car does not have much in common with the production model, so it was surprising in 2008 to see that our production model was almost identical to the show car,” says Kiska. “In 2007, people thought we would not be mad enough to actually build the car, but that is exactly what we did.”

KTM formed a new company in Graz, Austria, to produce the X-Bow – KTM-Sportcar Productions GmbH. In June 2008, the first X-Bows were produced in this new, purpose-built plant, and delivery to customers started in August. From 2009, the plant will produce from 1,500 to 2,000 X-Bows per year.

As part of its IDD process, Kiska carried out design work relating to the X-Bow’s product environment from the printed promotional materials, trade show presentation and exhibition stand design, through to photo shoots and the making of an action movie. “Everything relating to the X-Bow project was originated from us since the idea first saw the light of day,” says Kiska. “From the market analysis to the strategy. From the product itself to the product environment right up to the communication and presentation of the car. From classic advertising to the branding of the truck on which the X-Bow travels, and the t-shirt worn by the mechanics – Kiska designed it all. The upshot of this is a consistent appearance, a unique identity of which we’re proud.”

The car has received fantastic coverage and sales have exceeded KTM’s expectations, attracting a whole new market to the KTM brand. But the key question is, what is it like to drive? Stassin, a petrol head who regularly rides KTM motorcycles, says: “This is an unfiltered driving experience. Lightweight, rapid acceleration and amazing driving dynamics. The ride is not harsh and can be enjoyed for extended drives. The KTM X-Bow is the only car that motorcyclists wave at with approval.”

www.kiskadesign.com, www.ktm-x-bow.com

Technical Data

Weight 790kg

Length 3738mm

Width 1900mm

Height 1205mm

Acceleration 3.9 seconds to 100km/h, 8.9 seconds to 160km/h

Max lateral acceleration 1.5g

Max speed 220km/h

The new X-Bow has the exhilaration of a motorbike on four wheels