Giant steel chimneys are often their own worst enemies when it comes to strong crosswinds, making dampers for the lanky industrial towers a must have.

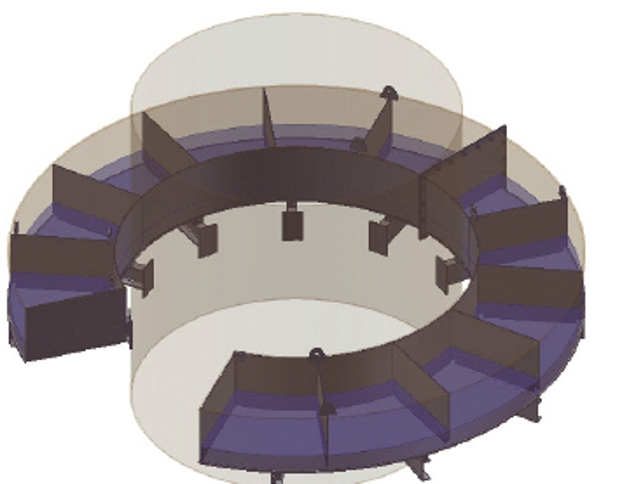

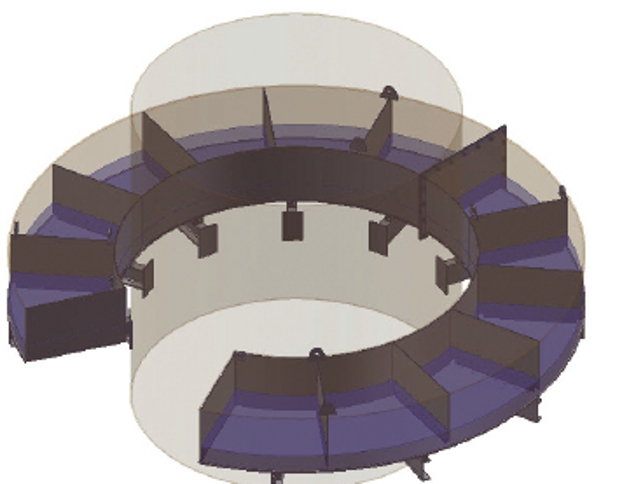

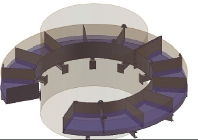

A 3D image of a damper

A cost effective yet highly technical solution for minimising vibration on the chimneys, often found in steel manufacturing plants are dampers. “You can design a chimney and make it very economically viable by fitting a damper from the very outset,” says director of Multitech Vibration Control, Chris Pegg, a vibration damper design specialist company in the UK with its headquarters in France.

Designing, manufacturing and installing damper systems, Multitech fits them to the top of the giant chimneys to stop the various wind forces they face. “Dampers stop the excessive cross wind movements that occur as a result of the response of the chimney to the shedding of Von Karmon Vortices in the chimneys wake,” explains Pegg. “Or as a result of buffeting from upwind structures, and thus control these movements along with resulting stresses and minimise or eradicate fatigue.”

Frustrating work

Multitech traditionally designed the chimneys by hand with the help of spreadsheet software, but taking account of the sometimes 12 or more openings in a chimney shell for inlet apertures; trying to accurately determine the chimneys natural frequencies and mode shapes, it proved a complicated process.

These difficulties led to an attempt with Autodesk Inventor 3D modelling software for the design, incorporating Robobot Structural Analysis: a structural analysis software.

With FEA capability, Robobot is specifically geared for codified steel design, and Pegg gets the most benefit out of the package for this purpose.

“The FEA capabilities are good [in Robobot] just not as well suited to what I was trying to achieve,” he says. “I went down the route of Inventor knowing that it had some FEA capability that I explored, but the idea was that I would send 3D SAT files over to Robobot and I could open them without the timely frustration of getting my model with many apertures and stiffening going.

But it didn’t quite work out how it was supposed to,” states Chris. “Inventor has come along greatly in terms of what it can do with regards to FEA but it just won’t handle the large thin-walled structures that we have to deal with.”

As a result Multitech started to look around for simulation software and evaluated five simulation packages including Algor, Ansys and Cosmos. “I carried out thorough research because I didn’t want to spend the money and then find out that I wasn’t going to be able to use it or I wasn’t going to be able to do what I wanted to do.”

Under one roof

Autodesk Algor Simulation software, with its finite element modelling tools nosed ahead of the other packages, with the firm purchasing it from Autodesk reseller Envisage.

Having already invested money in Inventor, it seemed a sensible progression to maintain a system that could all work under the same umbrella with the fewest hiccups. “Robot Structural Analysis is now an Autodesk product as well. So I thought that in keeping it all under the same roof the file compatibility was sure to be there for the future regardless of anything that happened,” states Pegg.

Beginning to use Algor from the start of this year Pegg got past the initial quirks in using it, and is now fully taking advantage of all its capabilities.

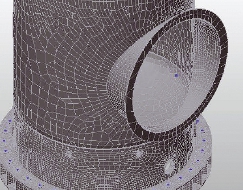

One of the features he gets the most advantage from is its meshing capabilities: “Being able to decide on what type of meshing you actually want to do is a really good thing – you can go from mid plain, surface to solid meshing depending on what is best suited to your model,” he describes. “You can select the solver that you require for the job in hand or you can just let it automatically sort it all out for you.”

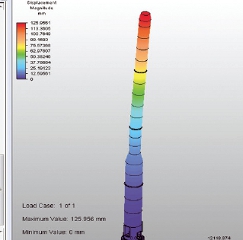

He recently used the software to assess two wildly windswept 70 metre high chimneys at a metals company in Wales. An assessment and design through its new software suite and Pegg and the team had designed the dampers, the frequency determined for apertures, ladders, platforms and everything else needed for the job.

Heat is on

As well as utilising FEA stress and modal/vibration analysis capabilities of the software Pegg also made use of the heat transient flow analysis in order to analyse the impact of temperature profiles on the design.

“The reason we used heat transient flow analysis was because we knew that the wall of the chimney was going to be around 70 degree celsius but as we were fitting a fluid damper to the chimney we didn’t want the temperature in the damper to get too hot otherwise you start to boil the liquid and you just end up creating a small pressure vessel,” he says. “We used Algor to analyse the temperature drop from the chimney wall through the support steel back to the damper system itself, which showed that the temperature was going to be just fine.”

Algor was also used to prove that the strengthening work that Multitech had done to the chimney was going to be suitable.

In fact, Chris had attempted to model these chimneys in Inventor before he had purchased Algor but had been unsuccessful with the thin walled structure being just too big.

Testing a Beta version of Inventor 2011 to try and see whether its FEA capabilities would be any better it still wasn’t sufficient. “Before I got my hands on the Algor software I must have lost well over a week just trying to make Inventor take the mesh and the same with Robobat. Then low and behold a day and a half learning curve with Algor and the following day I had got the model going,” says Pegg.

As a result, one of the major benefits of Algor for Multitech has been the sheer amount of time and frustration saved in being able to generate an FEA mesh and analysing the structure to solve the problem.

Instead of struggling with the models, it’s now a simple case of creating the 3D design in Inventor and then sending the file to Algor for it to mesh and solve. “With some of the other simulation packages I looked at you would basically hit go and have to wait a few hours for it to solve,” exclaims Pegg.

“That may be my own lack of skill with the packages, but with Algor you hit go and you might be able to turn around and do something else for 10 to 20 minutes but that is the maximum you are ever going to be waiting for it. So time-wise it has made a big difference to my life.”

Future focus

Although it’s still early days, having only invested in the software at the beginning of the year, Multitech feel that the investment may have already paid for itself. “It’s a very good piece of software and I have certainly had quite a lot of use out of it, it has certainly not been shelf-ware,” concludes Pegg.

Next up is finding the spare time to play around with all his new ‘toys’ and seeing what they have to offer – CFD calculations such as gas flows, pressure losses going through the ducting and chimneys, and trying to model air going around a structure to see how it responds.

The industrial chimneys of the UK will be a lot safer for Pegg having a few spare minutes with his new bag of tricks.

www.multitech-vibration-control.com

www.envisageuk.com

Algor pays towering dividends for vibration damper design specialists