Generating power from flowing water is nothing new, but Energyminer is looking to do it without dams or weirs that interfere with nature. Stephen Holmes learns how simulation technology is enabling it to test its Energyfish power plant across multiple rivers in a fraction of the time than would otherwise be required

Hydropower is one of the primary sources of renewable energy at work today, producing over 60% of all sustainable energy, but its deployment comes with some limitations. Building weirs and dams is expensive, resource-intensive and can have negative environmental consequences.

But many of us live and work close to moving bodies of water, be they rivers or man-made canal networks – so what if removable and replaceable energy generators could be deployed in such locations, acting as convenient sources of electricity?

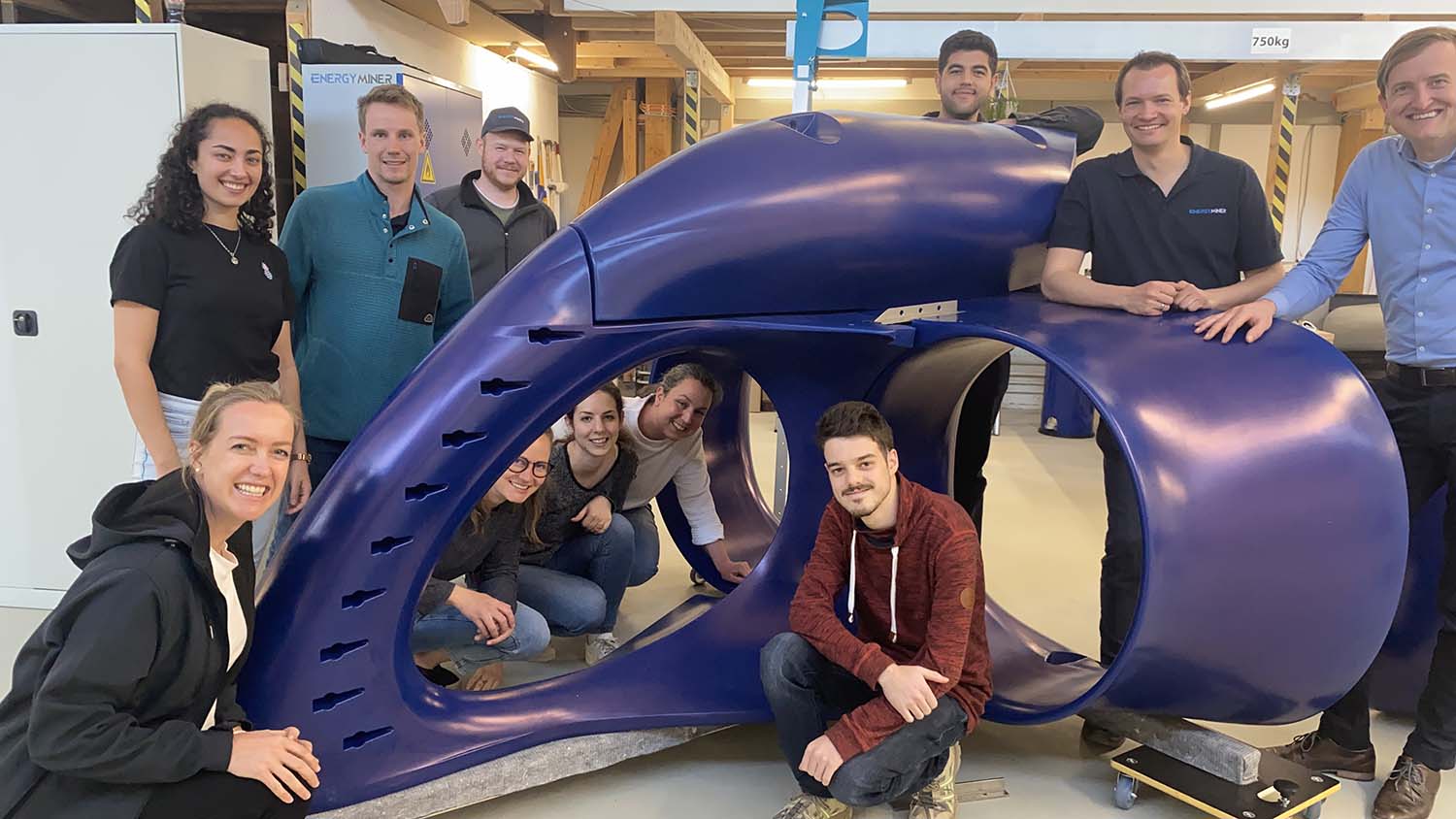

That’s the thinking behind clean energy start-up Energyminer, where founders had the goal of creating a hydrogenerator far more versatile in terms of placement than more traditional approaches. The idea was to instead build energy ‘fish’ – small generators, to be anchored in a stretch of waterway, with ‘schools’ of up to 100 fish deployed. Each Energyfish is small enough that it doesn’t take up much space in the river, keeping the environmental impact low.

Based in Munich, Energyminer’s two founders Dr Richard Eckl and Dr Georg Walder began discussing the concept back in 2020. In 2023, Chantel Niebuhr, a specialist in hydraulics and fluid mechanics for civil engineering, joined the team as CTO.

One of Energyminer’s first tasks was to assess where its fish should swim, prompting an analysis of German rivers. As Niebuhr explains: “You need to choose the size of your power plant according to what you have available, because you want to be able to utilise as many resources as possible. So that set out the design parameters.”

Questions asked included: How deep are most of the rivers in Germany? How deep is a typical river section? Where might Energyfish be most effective in size, so that a deployment could be scaled laterally in terms of arrays, but not require a massive turbine that only fits some 5% of river sections?

Key to this initial research was an academic study that looked at how best to fully utilise hydrokinetic energy in river sections. Niebuhr suggests that much of the time, links between academia and industry aren’t used to good effect, but Energyminer sourced the latest knowledge available, bringing new findings into its concept design process to create the most efficient design.

As a result, the design package for the Energyfish was limited to the size of a small car, allowing it to be transported on a normal truck, reducing installation demands and limiting environmental impact. “You never want to use up a lot of the cross-section of the river, so we always want to use only the first metre depth. And that’s why the Energyfish is shaped and built the way it is,” says Niebuhr.

Current thinking

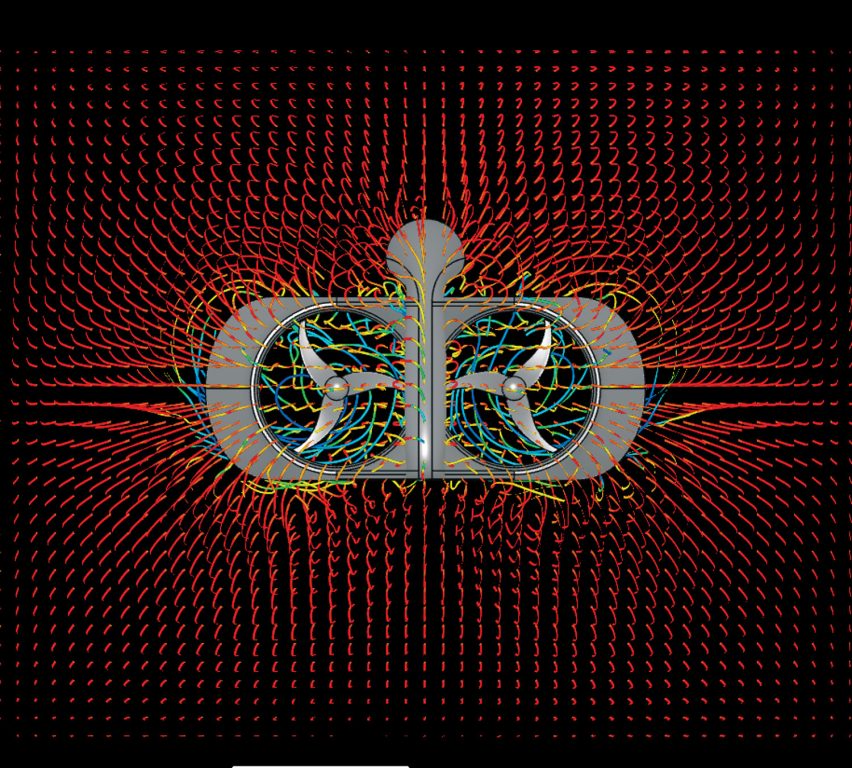

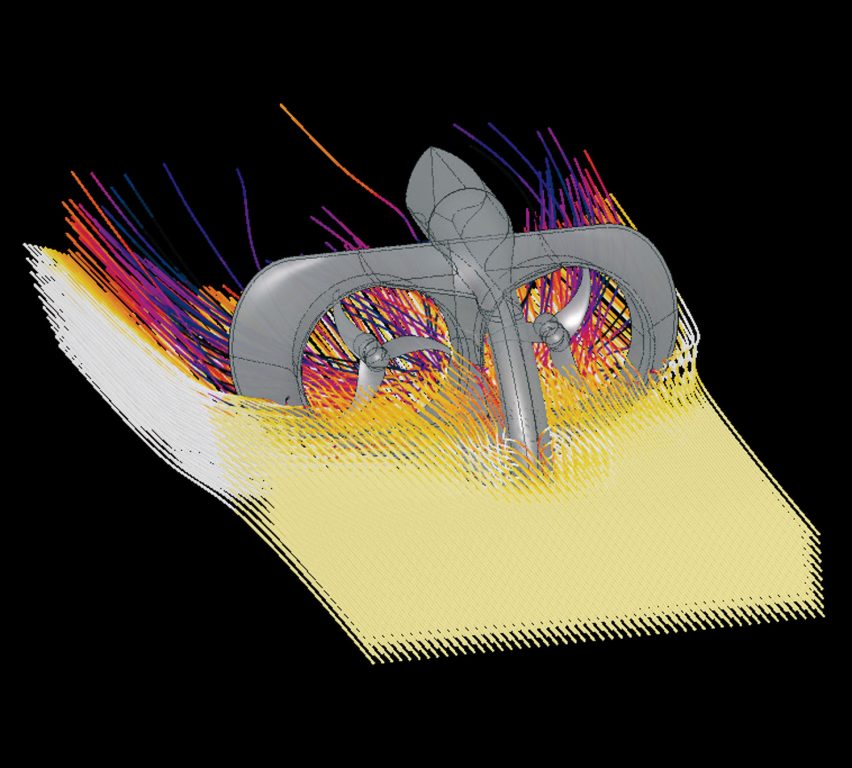

The form of the Energyfish is governed by basic hydrodynamic principles; these include considerations such as increasing the pressure over or around the blades to adjust buoyancy and achieving optimum flow velocity in slower river sections.

“Water flow is not something that’s so simple to analyse,” says Niebuhr, “and it gets very complicated, especially when you have rotating components.”

The first step to optimising the flow was to build an initial prototype, building a 3D model in Onshape, before the team got more hands-on, producing a working proof of concept that shows Energyminer’s hardware components working together with other electromechanical components within the structure.

With that first success under its belt, the process of optimising the design began. For this, Energyminer’s team turned to SimScale’s cloud-based CFD tools.

“Cloud gave us a very big advantage, because CFD is usually very expensive,” says Niebuhr. “A lot of people can’t do simulation themselves or use external consultants to do it. So we had a big advantage where we could do a lot of that in-house and that gave us a lot of information.”

Using a digital twin of the Energyfish, the team greatly reduced the need for live laboratory testing, and could compare a wide range of scenarios from different German rivers and canals, at different times of year. With physical testing, this would have been almost impossible.

“We could take all this complexity and actually analyse it in terms of our hardware,” says Niebuhr, explaining that this process answered many important questions: “How does it affect our housing? Where do we need more strength? Where do we need to maybe look at other materials? We can analyse all of that without even [building] another prototype, which is just extremely expensive.”

No two rivers are the same. Using SimScale allowed Energyminer to test its design in multiple flow conditions, in different river sections and then tweak designs in Onshape to create a product applicable to a wider range of water bodies.

“Working with those two together was just a perfect workflow for us,” says Niebuhr. “You can change something in Onshape, and then it’s imported directly into SimScale, and you can run a simulation again, and then see, ‘Okay, maybe we need to vary this a little bit’.”

Life on the water

The team’s latest prototype has been operating for over a year in a river flowing through central Munich, sending power to the grid via its low-voltage connection to a land box and validating much of the company’s simulation data at the same time.

When 1,000 kg per metre cube of water comes down a river section, even at 1 metre per second, that’s a lot of force to contend with – so it’s here that the team learnt what to expect from fluid structure interaction simulations. Rivers and canals, after all, are rarely free of debris such as tree branches, other vegetation, rubbish, even quite large objects.

In fact, the pilot project in Munich proved prone to unusual debris. “Everything gets thrown into this canal,” says Niebuhr. “There’s also a zoo upstream, so we have some wonderful biofilm growth, snails and interesting plants! It was a really good test for us and a big thing that we had to address.”

As a result, the Energyfish has been designed to be as debris-deflecting and self-cleaning as possible. It can also dive down out of harm’s way during floods or periods of faster flow.

“That’s just a question of buoyancy. When you have a certain pressure change or force on the structure, then it dives down, so it’s not sitting in this upper region, where all the branches and debris are floating in a flood event.”

Production is already underway and next steps involve installing a school of Energyfish in Germany, allowing Energyminer to test how a group works together in a typical river.

With over 4,000 rivers in Germany alone, it is hoped that these swimming generators of clean energy will soon produce greener hydropower while allowing nature to remain unspoilt.

This article first appeared in DEVELOP3D Magazine

DEVELOP3D is a publication dedicated to product design + development, from concept to manufacture and the technologies behind it all.

To receive the physical publication or digital issue free, as well as exclusive news and offers, subscribe to DEVELOP3D Magazine here