Ever since Dassault Systèmes, the developer of Catia, acquired SolidWorks in 1997, there has been constant speculation about the future of SolidWorks. Many predicted that it would be replaced with a ‘mini Catia’ and this certainly made sense as it meant that Dassault would be able to effectively service different levels of the supply chain.

However, when you have a product as successful as SolidWorks, the old adage of ‘if it ain’t broke don’t fix it’ is always there. And this argument must have held much weight in any Dassault/SolidWorks boardroom discussions over the years, as there have never been any clear signs that the two products would follow similar development paths. Until now, that is.

There’s a dump-truck load of technology coming your way. Brace yourselves for the mother lode

At the recent SolidWorks World Event, held in California last month, SolidWorks CEO Jeff Ray was joined on stage by Dassault Systèmes CEO, Bernard Charlès. This was the first time this had happened and it soon became clear why. Charlès and Ray were about to present a future vision of SolidWorks based on technology from Dassault’s V6 platform, which includes Catia V6 for design and Enovia V6 for data management.

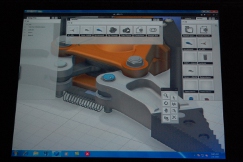

While neither Dassault Systèmes nor SolidWorks confirmed that this ‘new generation’ SolidWorks was based on V6 technology there were more than a few clues. The demonstration was live, using a hosted version of the technology accessed over the web. It showed a platform independent technology with talk of Mac, Windows, and Linux to name but a few. It demonstrated live access to data, hosted “in the cloud”, providing quick response search tools to enable data reuse. It featured direct manipulation of geometry, combined with more traditional modelling tools. Oh, and in addition to that, at the top of the modern, clean looking user interface it said SolidWorks V6.

Modelling with “SolidWorks V6”

From the brief on stage demonstration of the core modelling tools, it was clear that the SolidWorks R & D team is using the geometry-modelling kernel from Catia V6. The tools for geometry creation and modification, for data search and reuse, match the same shown in V6 demonstrations, both in terms of capability and focus. What differentiates the two appeared to be down to one thing: user experience.

The user interface and user experience surrounding those interactions was dramatically different to Catia V6, and this is very important. Many predicted that Catia (or a cut down version of it) would eventually be sold into the SolidWorks user base. But from what was shown on stage at SolidWorks World it would appear that this is not the case.

The demo was of a platform independent technology and Mac, Windows, and Linux to name but a few, were all mentioned

While typical Catia and SolidWorks users have similar requirements, they are fundamentally different in many regards. And if the V6 technologies become a common platform, one would assume that the two products will remain separate, with each having its own user interface, own methodologies and own target markets.

It is fair to assume that Catia will continue to focus on the strategic user where business process goes hand in hand with complexity (relating to product, of teams, of supply chain, etc), while SolidWorks will continue to focus on the mainstream community, where cost versus functionality continues to reign supreme.

The unity of V6

Dassault Systèmes’ V6 platform is arguably the first product development system to have its data management backbone so tightly integrated with the authoring tools. Not just 3D and 2D design tools, but everything – mechatronics, digital factory, simulation etc.

In most product development systems there is a disconnect between the two disciplines. This includes SolidWorks and EPDM, Siemens NX and Teamcenter, Pro/E Wildfire and Windchill. The 3D tool creates the data and the data system manages it. It’s a tightly linked system, but one that is built up of separate entities.

It featured a hosted version of the technology accessed over the web

Dassault’s Enovia V6 is starting to remove that distinction and within V6 everything is managed to a highly granular level. We’re not talking about revisions of parts and assemblies, it’s the live tracking of data to feature and sub-feature level on a massive scale – not only in terms of its ability to handle huge datasets (which are inherent in the granularity), but also in terms of the people who create, edit and access that data. Implementing this level of data management directly into SolidWorks would be an extremely interesting proposition.

The Cloud

One term that was everywhere at the event was “The Cloud”. This is possibly one of the most hideously over used phrases since “Innovation” became popular and lost its meaning entirely. I’ll not dwell on the subject because in this space “The Cloud” refers to a software product running on a web-server. That’s all.

The V6 platform is a server-based architecture. Data is stored and served from that server and is managed centrally. Users can interact with and access this data using a browser-based tool, a mobile device, or via a thicker client installed on a local workstation, it doesn’t really matter.

Following the SolidWorks demo it was clear that many seemed uncomfortable with the idea of a Cloud-based application and asked, “Does that mean I don’t own my own data?” Let’s be clear. No. It doesn’t.

With V6 whether you opt for the hosted service, one that’s installed in a privately maintained server from the vendor (Dassault is gearing up for this) or you have everything behind your firewall – it doesn’t really matter. There are many options. Think of it more as “A Cloud”, rather than “The Cloud.” When you do, it becomes far less intimidating.

Alongside the pure management of data, there’s also huge potential for compute intensive tasks such as simulation and rendering. For those working on a server-farm with 100s of available cores, assets can be generated immediately, as soon as they are required, on demand if you will.

It showed direct manipulation of geometry, combined with more traditional modelling tools

Rendering was demonstrated with Luxology’s Nexus engine (the same one powering PhotoView 360) and this was used to create photo real images in real time. The potential for design exploration in this type of environment, with massive compute capabilities available, is phenomenal.

Change and fear

For the ardent SolidWorks community that has been using its 3D product of choice for many years, the suggestion that SolidWorks could be set to undergo a major change is likely to come as something of a shock. And this is probably why SolidWorks decided to present its future vision now, to let its users get used to the idea, rather than spring it on them with a close to shipping product. But before panic ensues, let’s take a closer look at things.

SolidWorks is fifteen years old and we’ve all seen what happens once software reaches a certain age – it starts to clunk, look clunky and perform in a clunky manner. Fixing and more importantly advancing that code becomes a herculean task, and it becomes harder to stay competitive with newer, more agile systems. In saying that, deciding to build something new, with new technologies, is a brave decision to make.

That’s what Dassault did with V5, and now with V6, and while the transition continues to cause problems for some of its customers for others the results have been very rewarding.

To my mind the fact that SolidWorks is working with Dassault on a future incarnation of SolidWorks is good news. I’ve been covering Dassault and Catia for long enough to know that while the French company doesn’t like to talk about ‘product’, the things Catia can achieve are quite simply breathtaking. It can capture a product, in a digital form, in the most holistic manner. And coupled with Enovia manage the information very efficiently.

The coming years are likely to ones of transition for SolidWorks and its users (as it will for the IT world in general) and I don’t predict for a minute that it will be a smooth ride. But if you’re a SolidWorks user, don’t be afraid. Be excited. Because if this stuff comes to market, I am sure it will be incredible.

www.solidworks.com / www.3ds.com

There’s a dump-truck load of technology coming your way