Despite what you might read in the mainstream press, 3D printing anything is far from a one-click process.

When it comes to printing with metals, then this is especially true. Whether you’re looking at the adaptation of existing data for building in a sintering machine or looking to generate innovative forms that can

be manufactured no other way, then preparation is everything.

The good news is that, as you might imagine, there’s an interesting market growing up around the whole process, where the aim is to develop software tools to help.

Products in this category can be typically split into two camps.

The first focuses on the generation of geometry. While you can take your 3D CAD file and manufacture it using traditional STL-based methods, more recent years have seen the emergence of tools that focus more on free rules when it comes to geometry creation.

Whether you’re dealing with complex structures that solve mechanical or thermal issues in your products, lattice forms ideal for implants or you’re using computation to find new forms using topology optimisation, there’s something here for everyone.

Second, you have pre-processing software. This gives you a toolset to take your geometry and prepare it for production.

The goal here is to add in the supports needed, gather materials information and get your job running in as short a time as possible.

Both types of software products are key if you’re to reap the true benefits of this new means of production and get your job done.

Materials management tools for additive manufacturing

With the ramping of up additive manufacturing in some of the most heavily regulated industries such as aerospace and defence, it’s become increasingly clear that there’s going to be a need for more materials information management.

One of the leaders in materials management, Granta Design, has recently announced a variant of its Granta Materials Intelligence (MI) product for this exact purpose.

MI:Additive Manufacturing incorporates industry best practices in managing vital material and process information.

It helps engineering companies to protect their investment and intellectual property in additive manufacturing research; build the in-depth knowledge-base that is a prerequisite for better understanding of additive manufacturing processes; reduce time to market by avoiding wasted effort; and manage the qualification and certification of additively manufactured parts for compliance purposes.

The ultimate goal here is to ensure that data about the structure, properties and processing of all materials involved is captured and then used effectively across the many disciplines involved in the creation of a new product: materials supply, R&D, part design, simulation and production.

Generative design: a brief introduction

The term ‘generative design’ is one that’s bandied around with increasing regularity – but unless you’ve really dug into the details, its true meaning probably remains a little fuzzy.

The idea is that, rather than diving in and working up a potential new design, designers instead rely on the computational power of modern computing. A set of parameters, fed into software, is all they need to let the system take the strain and start to experiment with potential solutions to a specific design challenge.

There are a couple of ways that this idea has manifested itself in recent years. The first and perhaps most widely seen is the generative design of geometry.

Whether it’s a piece of 3D-printed jewellery or a high-fashion garment destined for the catwalk or even a dataset downloaded over the web, the process is roughly the same: define the parameters for your required form (the space envelope, for example) and have the system generate something interesting using its design algorithms.

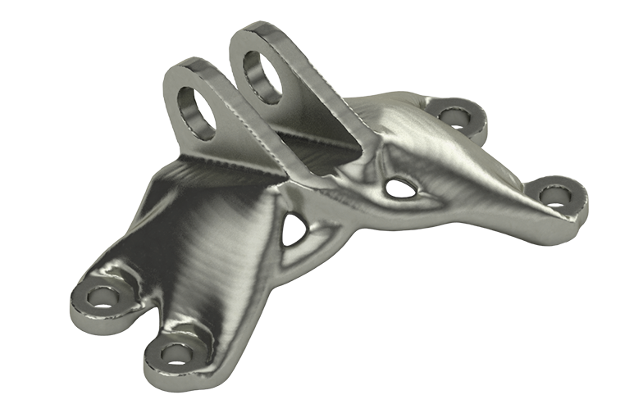

At the other end of the spectrum, the same principles are being applied to more engineering-type forms. The combination of generative geometry creation with finite element analysis, in particular, is proving to be a very interesting field.

While many of us might be aware of topology optimisation to reduce weight or mass in an pre- existing part or to explore new ideas, future tools will push this concept further.

Companies like Within Labs (recently acquired by Autodesk) and start-up Frustum are combining these technologies with the greater freedom afforded by additive manufacturing, to allow us to design and perhaps as importantly, manufacture, complex forms that solve design or engineering problems more efficiently in ways that couldn’t have been imagined or realised before.

Four of the most interesting

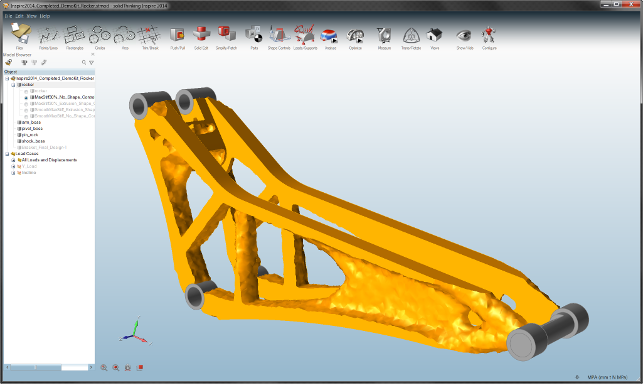

Autodesk Within

If you’ve seen a 3D-printed metal part that features lattice work and incredibly complex structures, the chances are that it was generated using Within Lab’s technology. Autodesk quietly acquired the company last year and has only recently given some hints about where things are heading.

For the last few years, Within Technologies has been developing two sets of software tools. One set is aimed at the medical market (for generating forms that mesh well with surrounding tissue, a process called osseointegration); the second focuses on generating tools for the industrial space.

Applications: Generation of lattice/complex structures in the engineering and biomedical fields.

SolidThinking Inspire

Topology optimisation isn’t a particularly new field – it’s been around for a good few decades. The issue has always been that it was a complex field of study, delivered through some pretty impenetrable tools.

What Altair did with SolidThinking Inspire was to take the same technology underlying its industrial/aerospace focus tool OptoStruct and build it into its industrial design products, while stripping back all of the complexity.

As it stands, SolidThinking Inspire is a fantastic product for taking a design envelope and a given set of loading and boundary conditions and using the system to explore potential new forms.

Applications: General engineering optimisation within specific geometry and performance conditions.

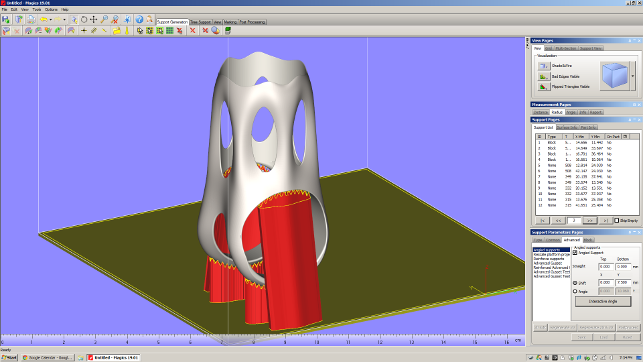

Materialise Magics

If you’re engaged in the business end of 3D printing, then the chances are you’ve come across Materialise’s Magics system. No other vendor is providing the sort of tools that Materialise offers with Magics and the company’s decades as one of Europe’s leading service providers means it has deep knowledge of how these things work in the real world.

From geometry fixing, pre-processing and support generation (per device and per process) to managing the whole process, Magics is the daddy of them all and looks set to stay that way for years to come.

Applications: All the print pre-processing and process management tools you could ever need – and then some.

Frustum, Inc

Details are thin on the ground about what exactly Frustum is planning in the coming months. With a team that includes former Autodesk technologists and ex-aerospace engineers, it certainly looks interesting.

Using the cloud to solve computationally expensive problems is a given these days and it looks like Frustum is building a cloud-based solution (cloudmesh) to solve some pretty meaty problems in the generative design space. It’s current taking details for those interested in beta-testing its system.

Applications: Perhaps the first additive manufacturing-focused topology optimisation tool.

The tools available for those looking to take advantage of the tech

Default