As living spaces shrink and cooking habits change, Kenwood Limited took the bold step of creating a new product range to meet modern needs. Stephen Holmes steps into the kitchen with the Go Collection to hear how its designers achieved the right blend of ingredients

Kenwood Limited’s newest range of small kitchen appliances evolved from an updated understanding of how many of us choose to live now, according to the brand’s design director, Samuele Meda. In particular, we’re opting for more compact living spaces and moving home more often. “Like me – I’ve moved nine times, and every time, the kitchen is smaller,” Meda laughs.

He’s speaking to DEVELOP3D from Kenwood’s design offices in Havant, Hampshire. Meda is a design veteran, having worked for brands including Electrolux, AEG and Dometic in Sweden, before spending almost five years at Kenwood in the UK. More recently, he moved back to Italy, where he now oversees the design process from De’Longhi’s HQ, the Italian kitchen appliance company that acquired Kenwood back in 2001.

Given the deep roots of Kenwood’s stand mixers in traditional British kitchens, it is unusual for a brand like this to undertake a pure, ‘clean sheet’ design exercise. The Go Collection was born to answer an unmet need, rather than update current models or compete with rivals. And the devices in this range demonstrate a distinct shift away from the classic Kenwood appliances of old.

Kenwood’s award-winning stand mixers, food processors and blenders remain much-coveted worktop kitchen appliances among those serious about cooking – but observations about how Gen Z approaches food prep indicated a clear need for simpler, more convenient tools.

After all, feature-laden machines with attachments to tackle almost every conceivable task can be daunting for some users. The idea of having to unpack and plug in another device and identify the right attachments is off-putting, let alone having to clean and repack everything once the work is done. Faced with a task like chopping an onion, many home cooks will opt instead for a knife and chopping board.

“So your competitor is not actually another food processor,” says Meda. “It’s something that the user at home finds much more convenient and easier.”

Smaller kitchens, often in apartments, also mean smaller work surfaces and storage spaces. With that in mind, the overriding goal for the Go Collection was compact products, ready to work and so intuitive that users don’t need to read an instruction manual.

The impact that Dyson’s hair care range has made on the beauty appliances market also influenced Meda’s thinking. “When I gave my wife a Dyson hair dryer as a present, she loved it, right? But years before that desirable hair dryer, I would never have given one to my wife as a Christmas present,” he observes.

That was the challenge he issued his team, he continues. “Would you ever give your partner a food processor as a present? We have to create a product that is desirable – and I believe that we can make a blender or a hand mixer or a food processor that is desirable.”

The result is minimalist products wrapped in matte, mellow tones of grey blues and clay reds. They represent a stark contrast from the chrome, stainless steel and black shiny plastic that we’re all more used to seeing. The stand mixer, hand mixer and food processor work straight out of the drawer or off the shelf. The few removable attachments stow away neatly in clever covers or nooks in the design, in order to save customers the chore of having to search through drawers.

Customers clearly approve of this approach, because the Go Collection has been a resounding hit both with users and reviewers.

Kenwood // The best ingredients

The starting point for the Go Collection was uncertainty, at least internally at Kenwood. Many on the team were not convinced that a move into a younger, more compact and more affordable range would suit the company’s market positioning. But when the green light was finally given, a team of six designers headed by Meda got to work.

The first week involved a classic design sprint – purely pen and paper sketching, idea generation and concepting.

“You’re in the phase where everything’s acceptable, right? We don’t need to restrict ourselves from giving crazy opinions and we work collaboratively. So the entire team is working together, not one designer,” says Meda.

At the end of the first week, three concept ideas were chosen. “There is no personal judgment. It’s not about ‘because we didn’t pick your concept, you’re not a good designer’. It is simply that we picked the best ideas and we really wanted to arrive at a maximum of three ideas.”

Week Two focused on identifying the best designs, involving two or three days of building out concepts in 3D CAD using Siemens NX. Other digital tools came into play for adding core technologies such as motors and switches to the designs, using Siemens’ PLM software Teamcenter and STEP files from supplier libraries.

The use of Siemens NX comes in part from Meda’s experience working as a designer for Electrolux in Sweden and the need to communicate closely with engineering teams, especially when it comes to electronics.

“Because we use the same CAD, we can all work on the same model. They understand you. You understand them. It’s a much more collaborative process,” says Meda. While he accepts that a software like NX can present a steep learning curve for many new designers, it’s justified by the results – closing the gap between designers and engineers, the reduction in waste and the preservation of design intent.

Meda has also adopted Shapr3D as his main, personal CAD tool. This originates from him always travelling and needing to open a 3D CAD file on his iPad and sketch over or annotate a quick screenshot using the Apple Pencil. Over time, the Shapr3D package has taken on even more purpose in Kenwood’s workflow.

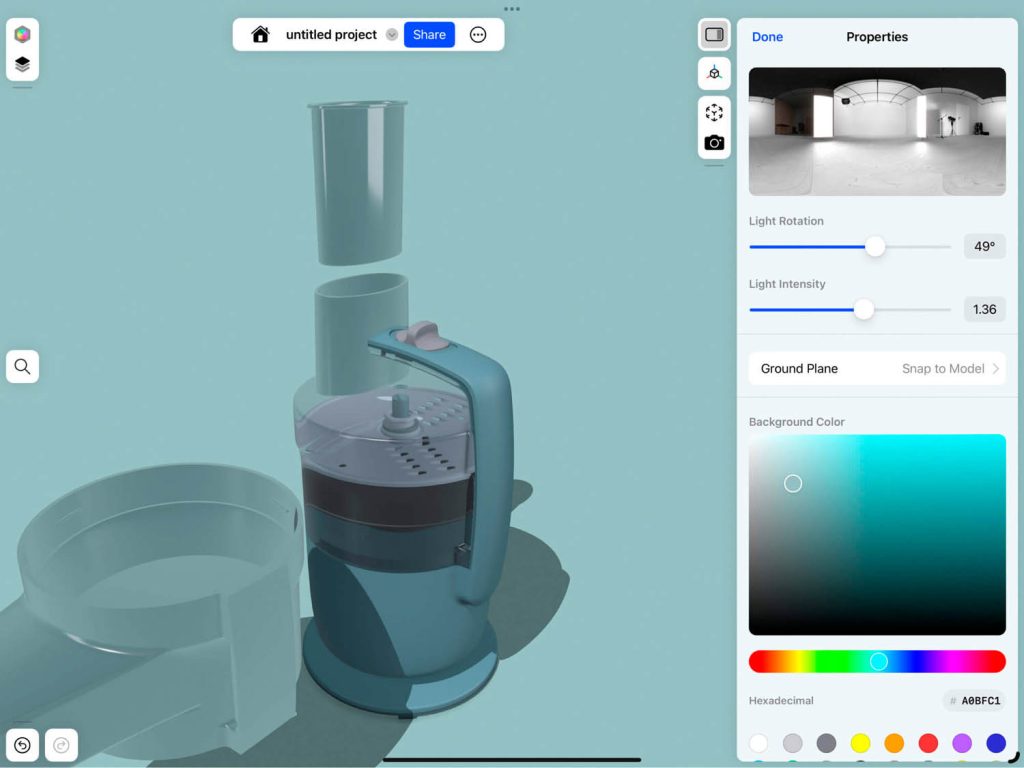

For the MultiPro Go food processor, Meda prototyped various positions of handles and buttons using Shapr3D, creating several concept variations with different styles of buttons for the user interface. Flying through concepts allowed him to test out multiple options and look at prototypes the next day.

The goal was to keep the design under 30cm tall, in order to allow the device to be stored in a deep kitchen drawer. Since the engineering team advised that only 35cm was possible, Meda’s iPad was brought to the meeting table, where he quickly edited the design in front of the team to show how the feed tube could be integrated in the top of the bowl. This gave the engineers the confidence to see that the design was possible and convinced them to try it out.

Whereas modifying a model in another CAD might take 10 minutes or more, and might confine the user to a desktop, this method proved effective in quickly conveying ideas visually, because everyone could get around a screen.

The right tools

Meda’s role is predominantly to give design direction to the team, and Shapr3D allows him to do this not only through sketches, but also by going into CAD models and being able to understand the limitations of dimensions or maybe even an undercut, he says.

“But it’s also fun, because I can open the file, I can visualise [the product], I can play with colour, material and finish. I can now use it with Apple Vision Pro. So, it’s this prototyping and collaboration dialogue between myself and my team.”

The use of Shapr3D is growing among the wider Kenwood design team, especially in the concepting stages to get into 3D modelling much faster. The knock-on effect of being able to 3D print prototypes and assess renders in XR for CMF is also welcome.

Kenwood’s design base in Havant offers a full workshop for prototyping, with all the 3D printers, CNC milling machine and spray booths needed to build rapid prototypes in-house. Yet it’s the use of the Apple headsets linked to Shapr3D that is having perhaps the biggest impact on how Kenwood’s team designs products.

“The CMF is something that [historically] we didn’t consider at the beginning. It was mainly shape, because we were used to having a 3D print or milled-out block of foam. And when you get that, of course, the CMF is not there, just a grey blob,” he explains.

“With the Vision Pro and Shapr3D, you can also simulate colours, material and finish – much better than just a form. We’ve learnt to design from the beginning with CMF in mind, and not just, ‘Oh, beautiful shape. Now, which colour do we pick?’”

This process has not diluted the team’s use of Siemens NX, he stresses. Instead, it has enhanced it, such is the speed with which a model can be exported as a STEP file, and then quickly pushed through Shapr3D into the Vision Pro headsets to quickly render and add colours, textures and materials.

With four Apple Vision Pro headsets in the UK office, team members can all get around a product virtually, testing out multiple models with colours, or even different features like dials or buttons. Now that he’s based in Italy, Meda can join in reviews securely from De’Longhi’s offices or even while on the move, with the session driven by a team member in the UK.

“Of course, it will never look [precisely] like the real one,” he admits, “but you’re making decisions and choices based on something that you can actually see now!”

Comprehensive CMF

For the Go collection, some colour, materials and finish (CMF) inspiration came from the likes of modern audio equipment, explains Meda. In that sector, the huge visual presence of old hi-fi set-ups has been replaced by WiFi-enabled smart speakers that blend into their surroundings more seamlessly.

“We wanted to apply a similar approach to our appliances, so you can have a nice piece of decoration in your kitchen and it doesn’t look like an appliance, both from a styling point of view, but also to make it more desirable and more an object that you want, not necessarily because you need that object.”

Because of this, the CMF was tailored to fit into modern kitchen environments with muted colours and matte finishes. To develop these, final CAD models were taken into Luxion KeyShot, allowing the team to create still and animated renders and drop them into different pre-built kitchen models, complete with colours, textures and lighting – allowing the team to quickly place the appliance in a variety of homes reflecting different styles and tastes.

Kenwood UK also invested in a powerful workstation for the studio, enabling the team to run KeyShot renders, “very, very fast, especially for videos”, says Meda. “You can imagine – there are lots of frames to be rendered.”

While final decisions are always made using what Meda calls a ‘hi-res’ physical model, built by hand for each colourway in De’Longhi’s main model shop in Italy, before being shipped to the UK, getting to this final decision is accelerated not only by renders, but by testing colours physically at an earlier stage.

Using the Swedish NCS system for standardised colours based on human vision (an approach Meda brought with him from his time at Electrolux), three shades of each colour were picked before a local supplier matched the NCS colour and provided it as a paint in a spray can. This proved to be a straightforward, cheap and pretty accurate means of testing colours on 3D models, as opposed to taking bets on a paper swatch or calibrated monitor.

“The swatch is nice, but when you maybe apply the colour to a kettle, maybe it doesn’t work, maybe it’s too much, it’s too dark, it’s too light, because it’s how it reflects the light.”

The final hi-res models are beautifully realistic and accurate in every facet, but given the time it takes to achieve this effect and then ship them across Europe, a 3D-printed prototype sprayed quickly with a rattle can in the workshop can help avoid lengthy errors.

Kenwood uses an external visualisation specialist for its final marketing materials, meaning that the requests and edits from its marketing team don’t eat into valuable design time. The agency in question also uses KeyShot, helping to maintain the link between teams by standardising on software choices.

Keeping the blend of software tight knit has proven effective for Kenwood’s design team, helping it react quickly to a new market opportunity and reinforcing its identity as an innovative kitchen brand for modern living.

This article first appeared in DEVELOP3D Magazine

DEVELOP3D is a publication dedicated to product design + development, from concept to manufacture and the technologies behind it all.

To receive the physical publication or digital issue free, as well as exclusive news and offers, subscribe to DEVELOP3D Magazine here