Automotive design is notoriously secretive. Locked away in their studios, designers and engineers shroud themselves in secrecy whilst developing the cars of the future.

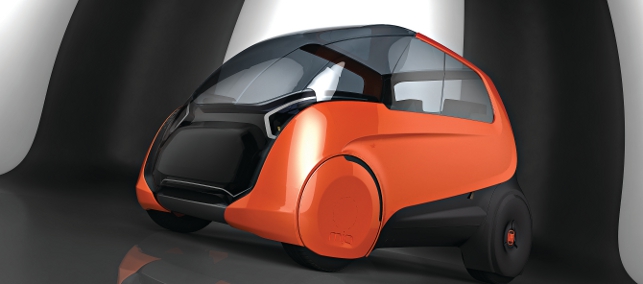

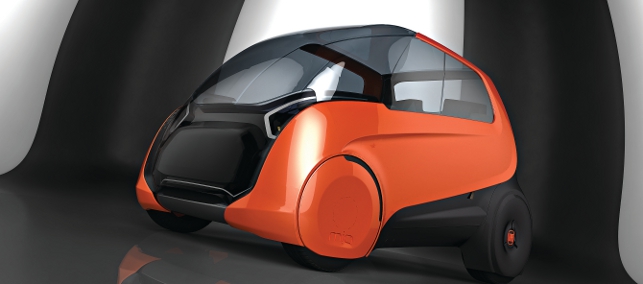

Developed in Fiat’s Latin America Style Centre, the car of the future is compact and economical

But the Fiat Mio concept, which was launched during the Sao Paulo International Auto Show in October 2010, represented a major step change.

Fiat’s Latin America Style Centre, based at the Fiat plant in Betim, Brazil, swung its doors open and not only let the public view the design process but actually invited them in to collaborate. According to Fiat, this made the Fiat Mio (Italian for ‘My Fiat’) the world’s first truly crowdsourced car.

“A good designer tries to realise the wishes of everyone and with this concept car we were truly working on everybody’s behalf,” says Peter Fassbender, head of the Fiat Latin America Style Centre. “The group of designers working on the Fiat Mio were totally open.

There was transparency about every decision, which were all communicated online and commented on. This is completely different to the usual design process, which is entirely hidden and secretive.”

In August 2009 Fiat launched the Fiat Mio project and invited people to submit ideas through the website www.fiatmio.cc.

During the actual design and development process, which took place from April to October 2010, Fiat regularly updated the website’s blog and also posted a series of short videos, called the ‘Making of Fiat Mio’, which documented each stage in its development.

More than two million people from 160 countries visited this collaborative platform where 17,000 were registered and more than 10,000 ideas were posted. “We’re the internet user’s hand. When he/she tells us ‘look you have to design a car in this direction’, we implement it,” describes Fassbender.

Against the grain

Fiat Latin America presented its first Fiat concept car (FCC I) in 2005 and in 2007 the FCC II followed.

In 2009 it embarked on the FCC III (otherwise known as Fiat Mio) but instead of designing it purely themselves the designers had the idea of tapping into inspirational ideas the public may have.

So, in a pioneering move they decided to make the design process both transparent and collaborative.

“The idea for the FCC III was to go further and to open our Latin American Style Centre to everyone so that they could assist us in building the model,” says Fassbender. “The idea was born with the design team and we got a lot of help from all areas of the company to make it work properly.”

With the website launched, ideas for the Fiat Mio started flooding in. These were then synthesised by Fiat staff and discussed by the design team who began to build a broad brief for the project.

Surprisingly, the overall theme was for a comfortable two-seater urban car that was compact, sustainable and economical.

“It was a surprise for us that the majority requested a small city car, which is unusual for Brazil where people seem to want lots of interior space in their cars,” comments Fassbender.

Some of the specific ideas submitted by the public included onboard biometrics, advanced touch-screen controls, mobile phone integration, cameras instead of rear-view mirrors, inter-vehicle communication to avoid collision and wheels that rotate to 90 degrees making it easier to parallel park.

The great challenge for the designers was to interpret these needs in a coherent manner. “Sometimes when people ask for a car that parks itself, they can be looking for more electronic assistance and not expecting the car to park itself as well as a human could,” says Fassbender.

Open for business

All of the ideas were submitted under the Creative Commons license, which means that participants can own their own contributions but they are free for the community to modify and distribute as it wishes.

So, although the notion of an open source car is that people will design their own car, it was for the Fiat designers to decide which ideas could be implemented. As Fassbender is careful to point out, the Fiat designers were more guardians of the car than creators.

“The requests changed from country to country and everything we did was a complication of all these different needs,” he says.

“We had very interesting ideas and some others that are impossible to manufacture even for a concept car. It was very important to have our designated design team working 24/7 on it, with direct and real time inputs from users worldwide.”

In April 2010 the sketching phase commenced, however with the diversity of ideas and suggestions the designers chose to develop two different directions for the Fiat Mio – Precision and Sense.

The former was characterised by its simple and minimalist form with well-defi ned lines and a focus on modularity whilst the latter had an organic shape with fluid and flowing lines.

These two different guidelines with their corresponding sketches were posted on the website for the public to scrutinise. From the comments received it was clear that Precision was the popular choice, but not by much.

“The final choice was 60/40 to Precision,” says Fassbender. “Even if there were greater numbers for the Precision line there was a lot of acceptance for the Sense line so, we agreed to also integrate some material from Sense into the Precision line.”

Role play

The designers then concentrated on honing and developing the Precision concept. Having created the exterior and interior style in Alias they handed their design to the engineers, who produced a 3D digital model of the entire concept.

The challenge was working out how to incorporate as much innovation desired by the thousands of participants involved in the project. “Actually, internet users don’t say much about the engineering solutions; it’s not their role.

The client’s role is not to tell me about solutions, the client has to tell me his requirements. I want a comfortable car, I want a small car, I want a car that is easy to drive in city traffic.

Our role as engineers and as designers, is to put together a solution for them,” explains Paulo Matos, innovation and technology supervisor at the Fiat Latin America Style Centre.

The clay modelling stage

In order to create an accurate 3D digital model, the engineers also carried out a variety of virtual simulation and analysis tests.

“In the virtual world we have countless tools to test the car. So we simulate as much as possible, working out how the solutions will be implemented, even looking at how the car will be built,” says Matos.

Of course, all of this work was being witnessed by thousands of online users who were following the design process very closely through the blog and video footage.

So the challenge was not only conceiving a solution that would work but doing it in full view of a virtual community who were quick to post their comments and views. “The challenge for Mio is doing the opposite of how we regularly do stuff . There were no secrets, everything was shown in real time.

Fiat Latin America Style Centre is one of the most secret areas of the company. The main change on this project was to build cameras and to bring the public inside our staff ,” says Fassbender. As well as the public posting suggestions there were also occasions when the designers asked them outright what their views were regarding a specific aspect of the design.

For example, three options as to how the doors could open were posted on the blog and the public were asked to select one. “Having thousands of people from all over the world giving real time inputs was the biggest challenge.

Since we built the Mio together with the public, we had to change features during the middle of the development phase of the process. It was not a frozen discussion,” stresses Fassbender.

“It was a very complex exercise to understand and create everything desired by the Mio community. We had to be quick and to work very hard. However, the direct contact with participants of the project was really challenging and stimulating for the design team,” he adds.

Brought to life

With the 3D digital model complete it was time to turn to clay modelling.

This is a lengthy process but having a full size 3D model is vital as it allows the designers and engineers to analyse the form, volume and lines of the car. A five-axis robot mills a huge slab of clay based on the 3D CAD data supplied by the engineers. If any changes or modifications need to be done these will be carried out by hand by the clay modellers.

Once everyone is happy, the clay model is then digitally scanned using CogniTens, a 3D white light measurement system, with the data sent back to the engineers for rework and refinement.

Clay modelling is one means of viewing a full size car in 3D but there is also another – virtual reality. In Fiat’s in-house virtual reality room the car in its entirety or individual parts are projected in 3D for the designers to scrutinise.

The 5.1 x 2.7m screen shows full scale objects but when wearing the 3D glasses the users can fully immerse themselves in the design and have a true sense of the car’s volumes, planes and depths.

Using virtual reality tools the 3D modellers can also place the design into various environments and scenarios providing a life like visualisation of the car. These tools can also be used to change the colour and texture providing a range of options to choose from.

“The virtual work saves us time in the prototype’s development. Our designers have much more agility in giving life to the ideas of internet users with this technology,” says Fassbender.

Although all these tools have obvious advantages in the development process, Fassbender claims that the success of the project is really down to the dynamic, young design team who were able to pull this project off in such a short time scale considering the circumstances.

“The most important tool in this project was the creativity of our designers and the courage they had to think differently, all the others are just technical tools,” he says.

Against the clock

With the Sao Paulo Auto Show looming, it was time to prototype and assemble the concept.

The final design measured 2.5 metres in length and featured a sleek appearance with camouflaged headlights, large glass roof and covered wheels that incorporates electric motors.

Inside it contains a floating dashboard with touchscreen display, a steering wheel which acts more as a central command centre as the car can be driven autonomously, and a two-seater sofa.

“The result was a direct response to the desires of our customers,” comments Fassbender. “Its shape and configuration was a mirror for the Mio community’s requests.”

At the launch of the Fiat Mio the designers involved in its development were at the Sao Paulo Auto Show to meet members of the public who had contributed to bringing it to life.

“I felt very happy to meet a lot of people from the Mio community at the Auto Show that approved the real model based on the sketches presented virtually on the Mio website,” comments Fassbender.

Although, the launch of the Fiat Mio was over a year ago it is still having an impact. Not only did it receive a number of prestigious design awards throughout 2011, but being such a pioneering project, Fiat Latin America continually receive requests to present, exhibit and talk about it.

For instance, Fassbender will be at the PLM Innovation Congress 2012 in February (see box piece) presenting a talk entitled ‘Crowdsourcing, Communities and Co-Creation’.

For Fassbender, the open source project has been an extraordinary experience that has led to new design thinking. “Mio is more than a car, it is an open space to discuss the automotive industry and the future of mobility,” he concludes.

Date for the diary

The PLM Innovation Congress 2012 will bring together over 500 senior representatives of the international product lifecycle management (PLM) community from across industry to network, benchmark and hear the latest developments in PLM.

Taking place in Munich on the 22 and 23 February 2012, the conference aims to leverage the collective wealth of knowledge and experience to identify and encourage best practice.

Uniquely, the format is technology agnostic providing an opportunity for organisations to understand new PLM processes and critically assess their own processes with organisations facing similar challenges while operating different platforms.

Alongside Peter Fassbender’s presentation on the Fiat Mio project, highlights of the agenda include: Thomas W. Schmidt, group vice president of ABB’s Power Products Division, who will be discussing why PLM is necessary but not sufficient; David Sherburne, the director of global R&D Effectiveness at Carestream Health Inc’s, will give his insight into the pros and cons of open source PLM; and Marc Halpern, the vice president of research at Gartner’s, will talk of his vision for Manufacturing 2.0.

Motoring by the masses: the crowd sourced Fiat concept car

Default