Industrial metrology can involve measuring pretty mundane objects. However, a recent project involved using a handheld laser to digitise an entire jet fighter

The first prototype of the Swiss fighter bomber jet, the P-16, had its maiden flight in 1955.

PolyWorks editing tools were used to optimise the model

It was celebrated for its revolutionary wing design that allowed it to take off on runways that were less than 500 metres in length and only required a landing area of 300 metres. Although the Swiss Air Force ordered 100 P-16s, following two catastrophic accidents relating to minor mechanical problems, the entire project was halted. Today, only one actual P-16 plane remains, exhibited at the Dubendorf Aviation Museum near Zurich.

Marc Immer, a mechanical engineering student at ETH Zurich University, wanted to digitise this historic bomber and analyse its aerodynamic properties by testing its scaled model in a wind tunnel.

“My intention is to recalculate the performance data of the aircraft. That way, calculations of flight performance – characteristics such as ascent and descent rates, stall speeds as well as the plane’s aerodynamic behaviour with the lowered and retracted flaps – will deliver the kind of information that has never existed for this aircraft due to the sudden termination of the project and the near complete absence of documentation relating to the development and the consequent flight tests,” explains Immer.

At more than 14 metres long, 11 metres wingspan and 4 metres high, the plane has a large surface area, with the wings alone covering nearly 30 square metres. This meant that the scanning equipment used had to be able to effectively cope with such vast surfaces yet deliver the desired accuracies.

On track

Having evaluated a number of systems, Immer opted for a Leica Absolute Tracker AT901-LR mated to a Leica T-Scan handheld laser scanner from Leica Geosystems Metrology.

A laser tracker is a portable coordinate measurement machine that relies on a laser beam to accurately measure and inspect in a large spherical volume. It can gather information in three different ways: by following a small mirrored sphere, by tracking a wireless, armless contact probe or by tracking a hand-held scanner, as was the case with the P-16 project.

The Leica T-Scan is coupled to the Absolute Laser Tracker by means of a digital camera system (Leica T-Cam) that operates with visible light and infrared (IR) radiation, with an optical vario zoom and a motor for vertical, angular movement. Mounted on top of the laser tracker, the camera system continuously follows the Leica T-Scan and captures the images of the IR LEDs located on it.

The camera’s incremental angle encoder is used to provide the vertical angular movement of the camera itself based on tracker guidance angles. The Digital Signal Processor (DSP), located within the Leica T-Cam, makes all the calculations and carries out all the image processing tasks, while the zoom lens group is completely sealed in the body of the Leica T-Cam. This design allows stable and repeatable measurements.

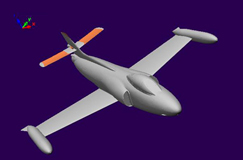

Completed CAD model

Over the course of two working days, a total of 40 million data points were collected during the P-16 scan. To create a 3D model suitable for CAD applications, the data obtained with the Leica T-Scan was imported into PolyWorks, the standard software suite for point-cloud processing used with the Leica T-Scan. That way, a polygonal model of the P-16 aircraft was created.

With advanced algorithms, PolyWorks averaged all data points and merged them together to create an accurate meshed model. The model was then cleaned and edited using PolyWorks editing tools to produce a usable and accurate digital representation of the historic aircraft.

“Getting involved in the P-16 project has made this research project extremely worthwhile, giving me valuable real-world experience with using the most advanced industrial metrology equipment available on the market,” concludes Immer.

www.leica-geosystems.com/metrology

www.innovmetric.com

A vintage bomber is modelled with a handheld laser scanner

No