Pilates is one of the world’s fastest growing workouts, so to support at-home participation, cult brand Fôld partnered with IDC’s design team to create a new reformer bed that can be stored away when not in use, opening the market to more users. Gabrielle Brown learns more

Pilates is one of the fastest growing workouts, according to the Sports and Fitness Industry Association’s (SFIA) most recent report, so don’t be surprised if your local studio is oversubscribed.

With Reformer Pilates, the challenge is multiplied, because of the equipment needed. After all, the reformer bed on which participants practice, with all its straps and springs, is a big piece of equipment that takes up a lot of space.

Undaunted, British home wellness company Fôld is on a mission to change this and the way people approach the activity, with a reformer that can be easily stored away when not in use.

“Fôld has always been about making wellness accessible to everyone, building a brand that breaks down barriers and challenges the ‘never miss a workout’ mindset,” says Fôld co-founder Matt Harras.

Fôld needed to make a studio-quality, 75kg home pilates reformer suitable for users of all strengths. The company partnered with London-based Industrial Design Consultancy (IDC) to create its next-generation reformer bed and develop a new mechanism to help stow it away when not in use.

Fôld // Folding feedback

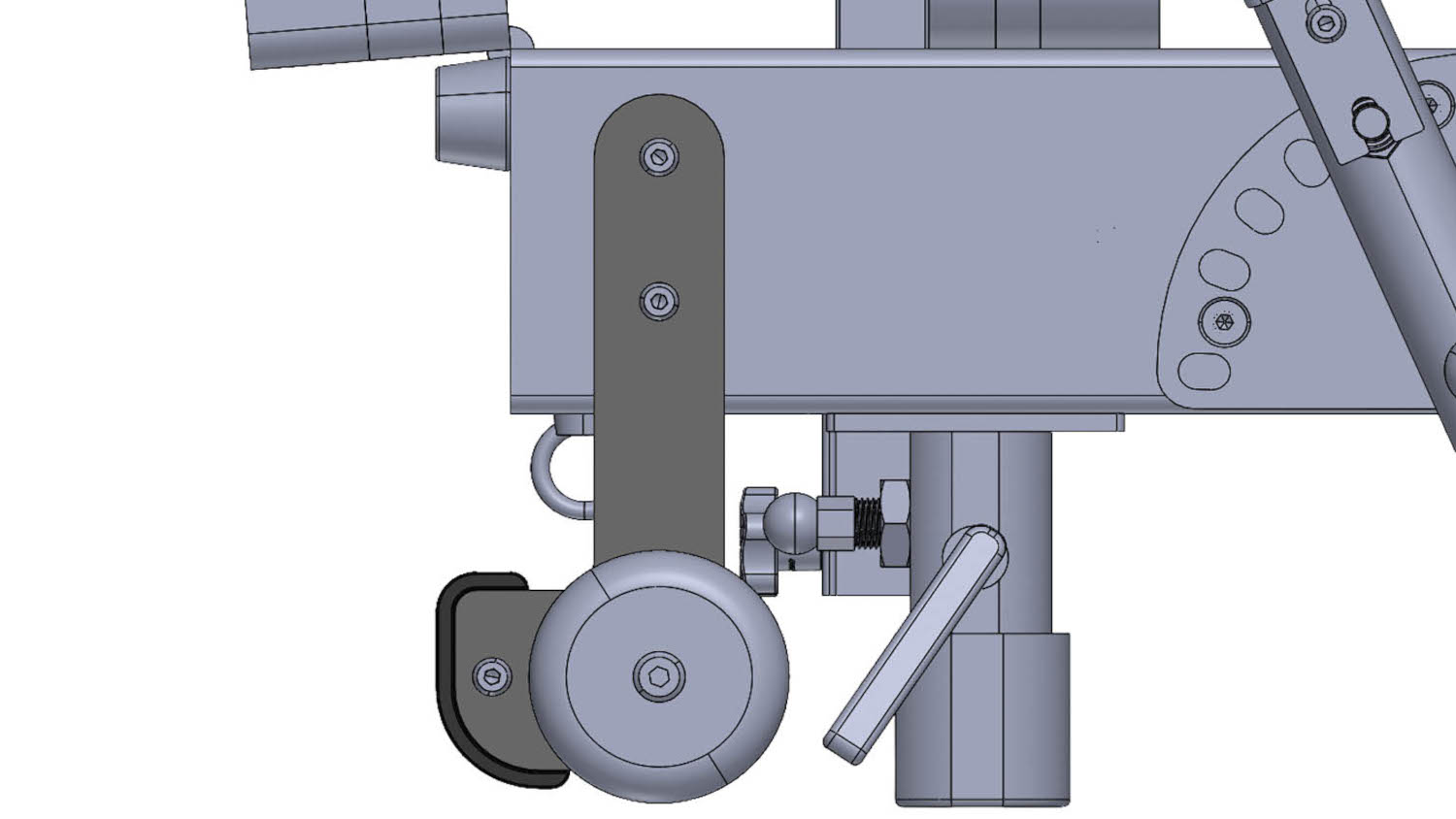

IDC began with surveying users and identifying areas for improvement on its first-generation reformer bed and set about redesigning its folding mechanism in response. Users found that the wheels of the existing design made the bed too mobile when folding and storing. The new spring-assisted mechanism, in combination with a rolling foot, improves usability when setting up the bed and packing away.

The team designed a progressive unfolding system; the heavier side glides open or closed, while the other provides stability with rounded feet that grip the floor and keep the bed stable while upright.

The bed and its mechanism were all developed in Solidworks, enabling the IDC team to quickly develop the joint, connectors and other parts, using its Bambu Labs X1 3D printer to produce parts that could help refine the rolling foot design, along with its onsite workshop.

“This project was about analysing all the strengths of the previous product and identifying all opportunities for improvement to take this next-generation launch to the next level,” explains Nick Chubb of IDC.

“The process of development was less pen-to-paper and more about group discussion around the existing product, followed by physical prototyping and testing right from the beginning.”

Being able to adjust the physical parts in real space helped the designers to better understand the behaviour and feel of the bed when folding and unfolding, something that Chubb says can’t be done in a digital space.

KeyShot was employed to help visualise different finishes and material combinations and to trial different wood finishes prior to physical sampling. When materials were decided upon, IDC’s office in Shanghai, China managed the process with suppliers.

So if your local Pilates studio does start to fill up, there’s still no excuse to miss a session.

This article first appeared in DEVELOP3D Magazine

DEVELOP3D is a publication dedicated to product design + development, from concept to manufacture and the technologies behind it all.

To receive the physical publication or digital issue free, as well as exclusive news and offers, subscribe to DEVELOP3D Magazine here