The Primus ladies running shoe features a super-thin sole to let feet feel the road

The human foot is a masterpiece of engineering and a work of art,” said Leonardo da Vinci in the 15th century.

With its 200,000 nerve endings, 26 bones, 33 joints and more than a hundred muscles, tendons and ligaments, it is indeed a complex mechanical structure. But, unlike da Vinci, most of us are too busy covering our feet to be marvelling at them.

With its ‘live barefoot’ mantra, shoe manufacturer Vivobarefoot is on a mission to inspire healthy natural movement and argues that we should be paying much more attention to our feet and what we put them in.

In contrast to many traditional shoes with their inflexible soles, padded heels and arch supports, the ultra-thin sole and wide toe box of a Vivobarefoot shoe allows your feet and the muscles in your ankles and legs to function naturally as though you weren’t wearing shoes at all.

“A foot that has lived in a normal shoe for a long time is usually quite a lot thinner. If you’ve ever been to the Far East and hung out with people that don’t wear shoes, you’ll notice that there is a lot of air between each toe.

The less shoe you wear the more natural your foot becomes. So, essentially we’re designing a product to let something natural occur,” comments Asher Clark, head designer at Vivobarefoot.

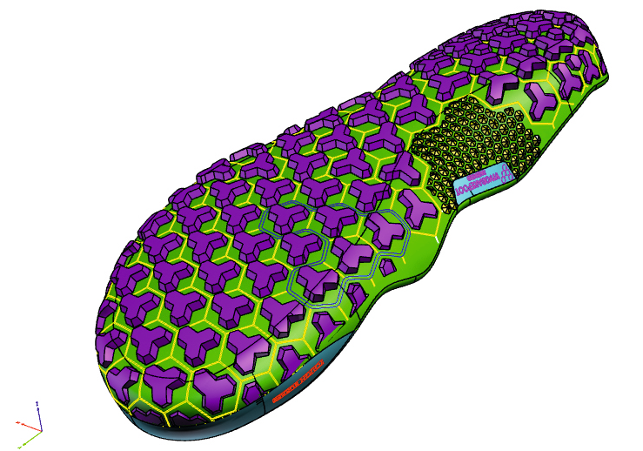

The Primus trail running version also features a thin sole but with the addition of rubber lugs

Foot shaped shoes

An accomplished footwear designer, Clark joined Vivobarefoot in 2009, which had been founded as part of a bigger shoe brand in 2004 by his cousin Galahad Clark, both of whom come from a long line of shoemakers.

Asher Clark’s initial focus was on running shoes and so immersed himself in the biomechanics of feet working closely with Lee Saxby, a London-based running coach and expert in barefoot running.

“We were really learning and understanding what the foot needs and how we can build a shoe to deliver free foot function, which is an easy idea but to execute it technically took us two or three years of trial and error,” explains Clark.

Following the successful release of its running shoes, in 2012 Vivobarefoot launched autonomously with a complete collection from exercise shoes to everyday lifestyle shoes and even a kids range.

However, Clark admits that it has been a challenge designing foot-shaped shoes rather than shoe-shaped ones especially as most of the fashion industry deems the natural shape of the foot as undesirable. “We call it the unfashionable foot,” he says.

“Shoes are usually symmetrical with big soles or heels so the challenge with our wide, flat, thin-soled shoes is to let the foot do its natural thing but to look really good while doing it because, in the end, aesthetics is the first and final key factor to pulling a shoe off the shelf and then walking out of the shop in it. The fact that it’s good for you just has to be a given.”

Asher Clark is the head designer at Vivobarefoot. Both him and his cousin Galahad Clark, who founded the company, come from a long line of shoemakers

User research

When it comes to designing a new shoe, before pen is put to sketchpad Clark first builds up a brief, which involves research with potential users.

In the case of two recent trail running shoes, time was spent with trail runners in both Sweden and South Africa talking to them about what they are looking for in a shoe and then also going out into the mountains with them.

“They can’t come out of that world and design a shoe for you but there is a lot of insight you can gain from listening and observing.

The challenge is to take the ingredients and try cook it into the best trail running shoe in the world,” comments Clark.

One of the key design challenges with this shoe, and its shoes in general, is durability.

“We are making very soft, foot-shaped shoes that move, flex, bend and crease more than shoes with stiff soles so durability is a very primary consideration in the design process and most of our innovation is about trying to reach industry defining standards in this area,” he admits.

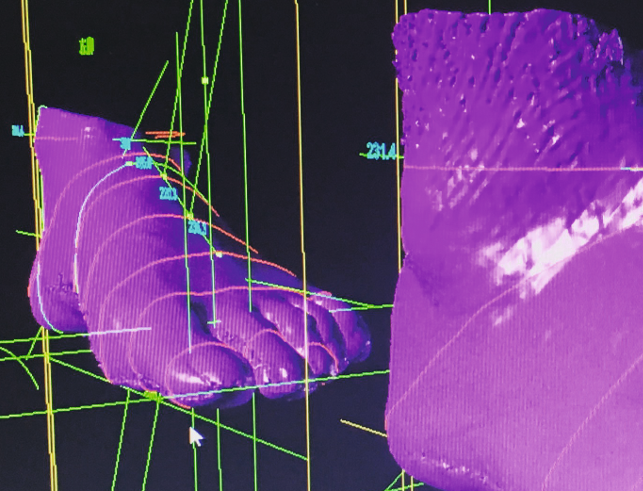

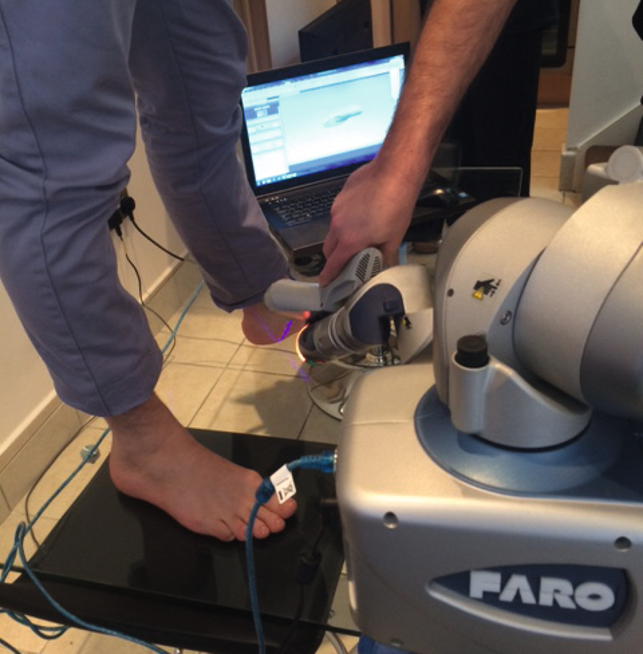

Foot scan where measurements are being taken for last development

Development process

The design process takes place between Vivobarefoot’s design office in London and its mouldshop in southern China, where most of the core development is done.

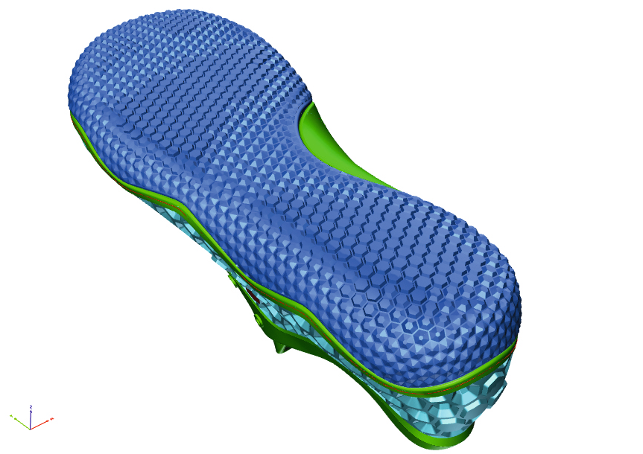

The process involves a number of rounds of CAD modelling using either SolidWorks or Rhino depending on the project, and physical prototyping and testing before the final design is reached.

“Typically shoes are in development for a long time but all the work we do is about designing efficiencies into the products so they are easier to make and have less parts and processes, which in the end makes a better product.

Like Albert Einstein once said, ‘make everything as simple as possible but not simpler’,” says Clark.

This long development cycle for shoes, as with a lot of other products, means working on the design of forthcoming ranges far in advance.

For instance, Clark is currently working on the Autumn/Winter 2017 range. One way he sees of combating this is through 3D printing — not the use of 3D printers as part of the product development process, but rather for printing the final product.

“3D printing will always be a growing part of what we do but the future of 3D printing in shoes will completely be around local manufacture. Buy the shoe online and print it at a depo or even at home,” he explains.

Firm ground outsole for trail running, available September 2016

Invest in feet

This is still a way off and although various shoe manufacturers are showing that they are innovating in this area, Clark argues that having worked with a number of 3D printer manufacturers over the past five or so years, although the technology is really interesting, the materials are just not up to speed.

“There will be incremental steps towards it and it’s all a question of how fast the polymers and materials evolve and how cheap the technology becomes,” he comments.

However, when the Clark cousins decided to launch a recent crowdfunding campaign on Crowdcube, they wanted 3D printing to play a big part of the marketing effort for it.

Called ‘Invest in Feet’, the aim of the campaign was to not only raise funds to help them grow the business but to also use it as a platform to show the world what Vivobarefoot is all about.

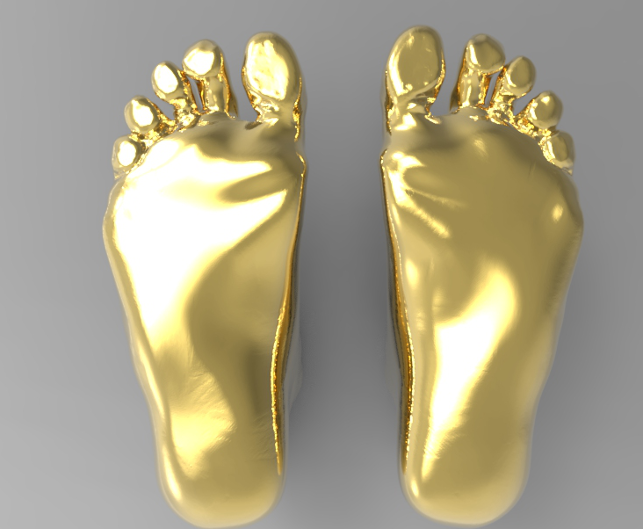

“We chose to call it Invest in Feet because when you choose to wear our shoes, you’re essentially investing in a foot transformation. So, we had this idea where an investor would have their shoe-shaped foot scanned and then handed a scale 3D printed model of it.

“Having worn our shoes for a year or two, they have their foot scanned again and a model produced so they can see the transformation to a foot-shaped foot,” explains Clark.

The plan was that at the campaign’s launch event, which would be held in March 2016 at Vivobarefoot’s London offices, investors would be given the opportunity to have their foot scanned there and then and a scale model printed in either plastic, bronze, silver or gold depending on their level of investment.

An amphibious fully moulded shoe outsole, available May 2017

From scan to 3D print

Vivobarefoot approached 3D printing bureau Printing Portal with this idea. “We could do 90 per cent of what they wanted but we needed help capturing the scan data,” says James Hawkins, director of Printing Portal.

For this he contacted metrology supplier Faro Technologies with the hope that its measurement devices could capture an accurate 3D point cloud file of a foot.

“Faro is known across many technical industry sectors that require high accuracy, repeatable measurements often in challenging conditions and complex setups.

So, this project was very far removed from what we normally do and we didn’t actually know whether it would be possible. However, we’re always willing to explore diff erent areas if we think there is mileage in it,” comments Robert Greenbank, Faro account manager.

Bringing the Faro ScanArm, a contact/non-contact measurement system that comprises the Faro Edge Measuring Arm with a hand held laser scanner, Greenbank went to Printing Portal’s office to work on a solution.

For the launch event, Vivobarefoot wanted the foot measured whilst it was under load as this would give the exact foot profile expected of a person standing upright under their own weight.

However, this presented somewhat of a challenge as laser scanning technology relies on line of sight.

“One limitation to scanning technology is glass; in order for our technology to function correctly it needs to be able to reflect off of the surface, component or object that is being scanned,” explains Greenbank.

“This then gave us the idea of scanning the bottom of the foot whilst positioned on a piece of toughened glass because in theory the laser should pass directly through the glass to pick up the object on the other side. After many tests and trials we found a piece of glass that was suitable.”

The 3D scan data was brought into the computer and software tool Geomagic Wrap used to transform this data into a solid model from which Printing Portal could create the mesh ready for printing on its Form 2 printer.

“We loaded the models to Preform [Formlabs proprietary software] and created copies to fill the bed with six model batches. With the settings customised at 50 microns using clear resin and reduced support material we completed a print in 12 hours,” comments Hawkins.

“We then took the models for post-processing, initially putting them in an IPA bath, then drying them off to use fine sandpaper to remove the support material tack points.

Finally a UV light chamber cures any remaining resin to create a nice smooth finish. Some final model making was done to help reduce the layer lines and various coloured coats sprayed on for display at the Vivobarefoot launch event,” he adds.

Future focus

At the launch event, the Faro system was set up to scan investor’s feet whilst the Form 2 was busy printing models.

“We had plenty of questions, everyone was really interested in what we were doing and how we were doing it. It was a great event that wouldn’t have been possible without the collaboration between a shoemaker, scanning specialist and digital fabrication/3D printing provider,” says Hawkins.

To scan the feet, Printing Portal and Vivobarefoot collaborated with Faro making use of its Faro ScanArm system

However, as Clark explains, this 3D scan data has another purpose other than for the printing of foot models. “We’ll use the data points of an average customer and a fully transformed foot customer to help us understand what the perfect mean shape is of our shoes going forward,” he comments.

With the crowdfunding campaign now ended and £1.4 million raised of a £750,000 target, it’s back to business for Vivobarefoot.

The plan is to deliver a new ecommerce platform, roll out new retail formats across its 20 international stores and grow the kids range. But Clark is also eager to innovate. “If there is anyone doing any next level ideas that they think they can apply to what we do, get in touch,” he says.

“We definitely want to be at the front of the curve and collaboration, as we did for the Crowdcube event, seems to be the way to get there.”

Vivobarefoot’s foot-shaped shoes

Default