With advancements in materials science constantly changing what it’s possible to achieve in product design, we spoke to advanced materials experts at Goodfellow about the emergence of new alloys, compounds and isotopes

Many of today’s most important materials didn’t even exist a decade ago. With designers and product developers increasingly looking to push back boundaries in pursuit of innovation, it’s at the materials level that some of their biggest gains might be made.

Goodfellow is a global supplier of advanced metals and materials, with an inside track on the innovation and insights shaping the future. The company is working closer than ever before with client companies – and specifically their R&D departments, life sciences specialists and engineers – to create solutions that are lighter, kinder on the environment and yet still capable of delivering high performance.

“Many of the technologies that will define the next 20 years, like quantum computing, hypersonic travel and clean energy breakthroughs, will depend on materials that didn’t even exist a decade ago,” says Goodfellow CEO Simon Kenney.

“What was once science fiction – materials that self-heal, adapt to environmental conditions or conduct electricity better than copper – are now entering real-world applications. And these materials are no longer hidden enablers. They are strategic assets shaping global competitiveness.”

In short, Goodfellow is a company that believes that materials are at the start of every good idea, at the base of every good product and are often the catalyst for fostering new technologies. With that in mind, DEVELOP3D sat down with Adam Sells, one of Goodfellow’s technical experts, to discuss six materials that could prove to be product design game changers.

Ytterbium-176

(Metals)

Over the past decade, advancements in isotope enrichment have enabled the high-purity production of Ytterbium-176, a stable isotope with applications in quantum technologies, precision timing and advanced materials research.

Using novel laser-based ‘quantum enrichment’ techniques, enrichment levels approaching 99.75% have been achieved, significantly surpassing traditional methods.

This breakthrough enhances the isotope’s performance in optical lattice clocks, fundamental physics experiments and next-generation sensing systems, marking a major milestone in the commercial availability of specialised isotopes for cutting-edge scientific and technological applications.

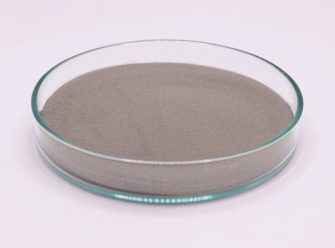

High Entropy Alloys

(Alloys)

High Entropy Alloys, or HEAs, are a new class of metallic materials engineered from multiple principal elements and offering exceptional strength, wear resistance and thermal stability.

HEA powders enable tailored performance for advanced applications, in areas such as aerospace, additive manufacturing, energy and healthcare.

Their unique microstructures provide superior fatigue and corrosion resistance compared to conventional alloys, opening new possibilities in extreme environments. Custom formulations and particle sizes are available to suit specialist research and production requirements.

Graphene-enhanced PLA

(Polymers)

Graphene-enhanced PLA combines the processability and environmental benefits of polylactic acid with the exceptional mechanical, thermal and electrical properties of graphene.

This advanced polymer blend delivers increased strength, improved conductivity and enhanced wear resistance compared to standard PLA, while remaining lightweight and easy to process.

Suitable for 3D printing, prototyping and functional parts, it enables researchers and manufacturers to explore innovative designs and applications. Goodfellow supplies this material in a range of forms to support both experimental work and small-scale production.

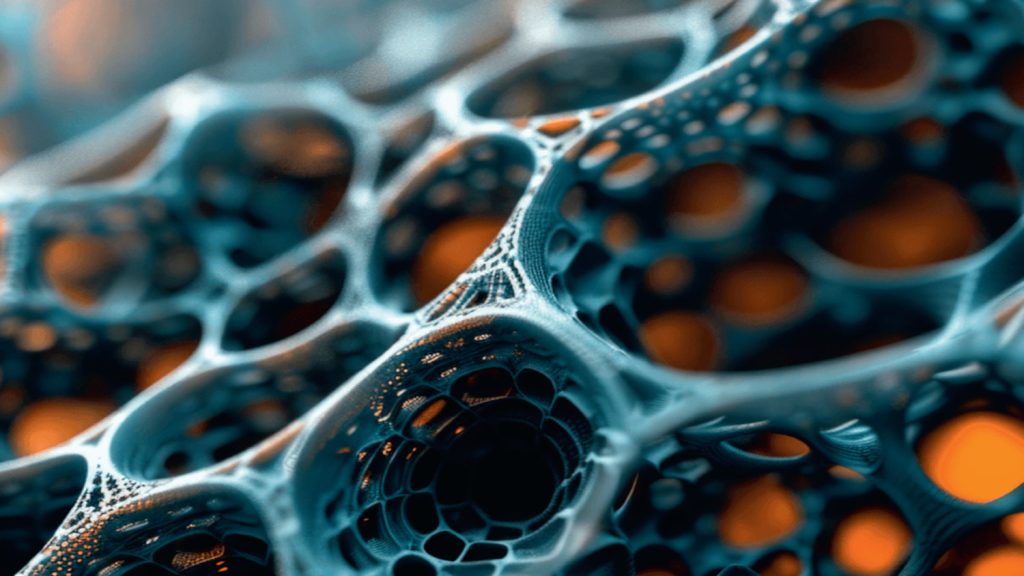

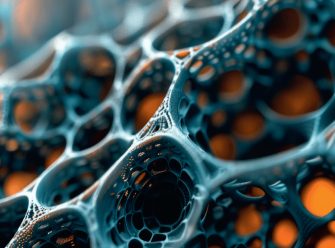

Metal-organic frameworks

(Compounds)

What was once science fiction – materials that self-heal, adapt to environmental conditions or conduct electricity better than copper – are now entering real-world applications Goodfellow CEO Simon Kenney

Metal-organic frameworks, or MOFs, are crystalline compounds composed of metal ions coordinated to organic ligands, forming highly porous structures with enormous internal surface areas.

Tenable pore sizes and surface chemistries make MOFs exceptionally versatile for gas storage, separation, catalysis, drug delivery and sensing applications. In the past decade, they’ve moved from laboratory curiosity to industrial target, because of their unique performance advantages in the energy, environmental and chemical sectors.

Continued research is unlocking new MOF structures with targeted properties for specialised high-tech applications.

5N Purity alumina powder (SupALOX)

(Ceramics)

SupALOX is a premium high-purity alumina powder, available in alpha and gamma forms, with purity up to 99.999%.

Manufactured using a sustainable, proprietary process, it offers uniform particle sizes, exceptional chemical resistance and outstanding thermal stability. High dielectric strength and optical clarity make it ideal for electronics, optics, advanced ceramics and catalytic applications.

SupALOX delivers consistent performance for demanding research and industrial environments, with options tailored to specific project needs. This material represents a cutting-edge solution for high-technology manufacturing.

Hastalex

(Composites)

Hastalex is an advanced graphene-reinforced composite material offering outstanding mechanical performance, durability and environmental resistance.

Developed for demanding engineering applications, it delivers high-tensile strength, excellent impact resistance and superior chemical stability while remaining lightweight.

Graphene reinforcement enhances electrical and thermal conductivity, opening up opportunities in aerospace, automotive, medical and sporting goods.

Various forms of Hastalex are available to support both R&D and production needs, enabling users to explore its potential for high-performance, next-gen product design.

This article first appeared in DEVELOP3D Magazine

DEVELOP3D is a publication dedicated to product design + development, from concept to manufacture and the technologies behind it all.

To receive the physical publication or digital issue free, as well as exclusive news and offers, subscribe to DEVELOP3D Magazine here