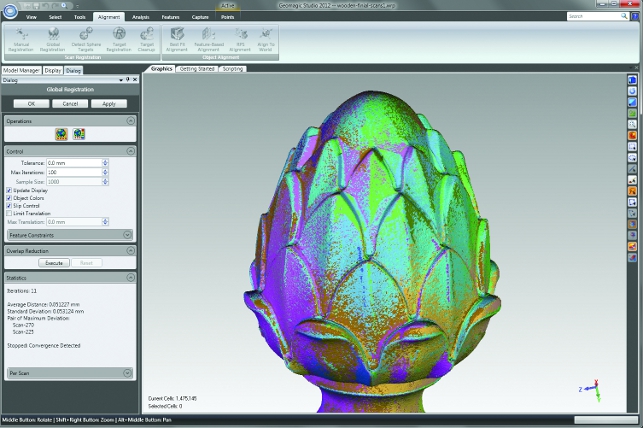

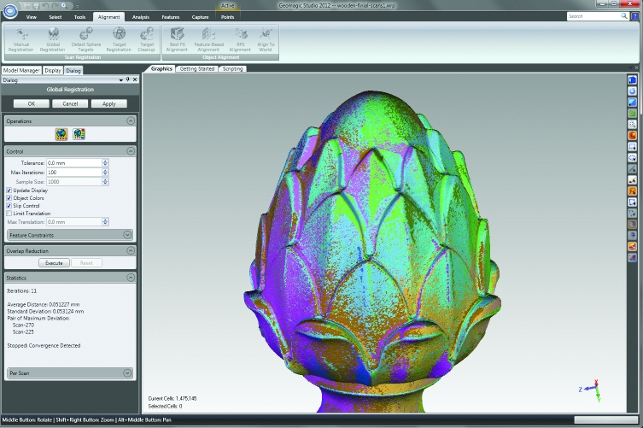

For those unfamiliar with the name, Geomagic specialises in the software that sits between a 3D scanning device and the user.

Geomagic Studio and Wrap give all the reverse engineering tools a design might need. Points, to Polys to Surfaces. It’s all there

Its Studio and Wrap products are aimed at those using scanning devices at the front end of the design process to capture forms, whether that’s from a clay model, a turbine blade or mould tools and dies.

The captured data is then outputted as either a polygon mesh, a set of freeform surfaces or a native CAD file. The last few release cycles have seen a great deal of work done on Geomagic’s product line-up.

The 2012 release sees this continue with work having been carried out on refreshing the graphics display across all the products, better support for multithreading and the introduction of a new scripting engine that, while formative in this release, will eventually lead to greater potential for customised applications.

The big update for those looking to reconstruct scan data are improvements to the sketching tools. For those users looking at creating 3D sketches, these now snap to the underlying point cloud geometry. Whilst for those working with more planar sketches, it’s possible to create a section and have the system match a sketch directly to the point cloud.

Remeshing tools

This is an interesting one. The polygon mesh, by which geometry is approximated by a series of interconnected triangular facets, is something that’s becoming a more widespread method of interchanging data, particularly if working with either reverse engineering tools and/or simulation technologies.

The problem is that the default mesh output by many reverse engineering tools is inappropriate for use in simulation. These typically have no concern with poor aspect ratio triangles, which can wreak havoc with simulation systems that prefer an ordered set of near equilaterals.

Geomagic Studio 2012 provides tools to very quickly take an unstructured and inappropriate mesh and remesh it to a type more suited for downstream work. There are controls over the size of the triangle faces used and the system can place extra concentration on the edge areas to ensure feature definition is maintained.

Reconstructing missing data

Working with scan data always involves an element of reconstruction. Either the hardware misses an area, details are missing or it simply can’t be reached.

In the 2012 release the new mirror geometry tool allows the user to select geometry that is flipped across the object, something that is fairly common.

Essentially, the user selects the opposite geometry, copies and pastes it into position and then uses the existing Patch command to merge it with the surround geometry, using deformation controls if needed.

Long range scanning

There have also been updates to how the system handles long range data.

While most of us will be familiar with scanning smaller objects, there’s a breed of capture devices and associated use models for scanning much larger objects in the aerospace, factory design or civil engineering.

Previously such a large amount of data could be unusable in any meaningful way, either due to pure density of data or due to the processing hardware. It is not unheard of for users to filter down a scan of the insides of a factory by a factor of 10 to make it usable.

However, Geomagic now has tools to deal with this quickly and efficiently. It also now has the ability to get ‘inside’ a dataset, which was problematic before. The user is able to set a camera view inside a scan set which is useful for walkthroughs.

SpaceClaim & CAD integration

The final update I wanted to cover was the CAD integration aspects.

For some time, Geomagic has worked to build relationships and interoperability tools that allow scanner users to transfer data between Geomagic Studio and the host CAD application.

They allow the user to transfer accurate, parametric surfaces, reconstruct feature trees or just send across a surface quilt for further reuse. At present this works with SolidWorks, Inventor, Creo Pro/Engineer) and Catia.

This release sees a different approach taken to SpaceClaim integration. There’s now a button to send the currently selected geometry to SpaceClaim automatically. This assumes that the two systems are on the same machine – if not, then you’re back to a normal STEP file.

Conclusion

Geomagic has been one of the quieter companies in the engineering space, perhaps due to the perceived specialism of the scanning process and the fact that it’s often outsourced.

This is due to change as we move into a world where the ability to reuse scanned data becomes more commonplace, especially with the rise of 3D printers. Geomagic itself has a rudimentary scanning system built with a Microsoft Kinect (yes, that was first integrated into the xBox of all things).

Also, within the inspection space, non-contact methods are gaining ground. So, the advances made with this release of Qualify and the introduction of Qualify Probe should see it gain greater exposure and adoption.

All in all, it’s a good solid release from a company that’s doing exciting things to bring functional and usable tools that not only solve their own issues in terms of capturing, cleaning and repairing data, but

also enabling users to do something useful with it once done.

Geomagic Qualify & Quality Probe 2012

Data translation has often been an issue particularly within the context of inspection and metrology.

The problems particularly arise within a subcontract or supply chain environment when inspection needs to be undertaken against native CAD data.

Geomagic has licensed the HOOPS libraries from Techsoft. This means that they can be distributed to all users at no charge.

In an inspection context,this allows 3D PMI to be read for use within inspection routines and also opens up the system to working with much more data from Catia, NX, SolidWorks and Creo Parametric (Pro/Engineer).

Another good update, which may seem a little left field, is the ability to invoke Geomagic Qualify commands using your voice.

Many might scoff at the idea of talking to their software, but in an inspection environment, it makes sense. Try using a measurement arm and operating a laptop at the same time.

The other big news is that Geomagic has introduced Geomagic Qualify Probe, a new variant of the inspection system.

It builds on new hard probing technology, but only works with those hard probe processes, whether that’s an articulated measuring arm, CMM or otherwise.

It allows the importing on the CAD geometry,full analysis and reporting capabilities but won’t work with scan data.

What it does mean is that those with mix inspection processes using both traditional tools and non-contact methods can standardise on a single platform.

| Product | Studio 2012 |

|---|---|

| Company name | Geomagic |

| Price | on application |