Since the first lightweight, collapsible wheelchair was invented in 1933 by the American mechanical engineer, Harry Jennings, its basic form has remained pretty much unchanged, until now.

With the use of new production tools, materials and manufacturing methods, British engineer Mike Spindle, has gone about quashing our perception of conventional manual wheelchair design with the Trekinetic K2 All Terrain.

No ordinary wheelchair: The Trekinetic K2 All Terrain combines good looks with excellent handling

This stylish front wheel drive wheelchair sports two chunky wheels at the front and a smaller single wheel at the back, a carbon fibre monocoque seat, a dynamic braking system, ‘varicam’ quick camber change, a telescopic footrest, a quick-fold rear assembly, a nitrogen shock absorber and onboard wet weather protection in the form of an automatic umbrella. It is no ordinary wheelchair.

Back in 2000 Spindle realised that his Hertfordshire-based engineering company – DT-Clayton Toolmakers – that had been making components for the F1 industry and previously tooling for the motor industry, needed to diversify into new areas in order to survive. Being quite a cash rich company and having invested quite heavily in new technology over the years, including a large 3-axis Haas CNC machine, Spindle was looking to design his own, relatively high value product. He stumbled upon just the thing whilst waiting in Luton airport’s departure lounge.

Having noticed a “cool lad” in a wheelchair he was struck at how out of place he looked in his traditionally designed, purple wheelchair. “I had no emotional involvement with anyone in a wheelchair and seeing this kid I honestly thought, is that really the best that wheelchair manufacturers can do?” says Spindle. Feeling inspired that he could create something better, he started sketching out his ideas on the back of his boarding pass during the flight.

A new beginning

With a ‘clean sheet’ approach, Spindle’s mission was to build a new wheelchair from the ground up. “I deliberately didn’t look at any wheelchair designs because I thought that I may be influenced. I was going to try and come up with something as if a wheelchair hadn’t existed,” he explains.

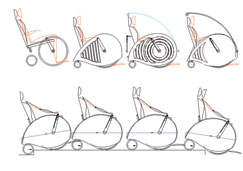

Study of wheelchair operator position in relation to front drive wheels

His initial concept and break from traditional wheelchair design was to move the smaller wheels, or castors, from the front to the back. He felt that, perhaps naively, with the castors at the front the wheelchair is more susceptible to tip backwards. He also thought that it would feel more natural for the user to have their hands next to their knees and not behind their hips. The original concept also included ratchet type levers attached to the wheels. “Instead of pushing the wheels I thought that the levers would be more efficient but, as it transpired, I was completely wrong about that,” admits Spindle.

From this kernel of an idea it took another six years and 14 separate prototypes before the K2 was ready for market. “The first prototype was made cheaply and simply out of plywood and didn’t look anything like what we have now,” says Spindle. “It was a front wheel drive wheelchair with two levers and two castors at the back.”

With that prototype he realised that the lever propulsion system was not the best solution. “When we developed it we found out that it simply wasn’t a practical method as it’s much quicker to move the wheels with your hands. A lever is too cumbersome, too expensive and it’s also difficult to put into reverse,” he explains. With subsequent prototypes Spindle discovered that a three-wheel design would offer a better solution as it meant that all the wheels would remain in contact with the ground, even on an uneven surface.

Sitting pretty

With a ‘clean sheet’ approach, Trekinetic’s mission was to build a new wheelchair from the ground up.

The real breakthrough came with the fourth or fifth prototype when Spindle decided to build the wheelchair around a moulded seat to which all the components would be attached.

“One of the remarkable things that I thought about when I saw the wheelchair at the airport was that it was still on a metal frame chassis with a seat plonked on top,” he says. He sourced an aluminium racing-car seat and weeks of painstaking measuring later, he had the CAD data that could become the basis for a comfortable and mouldable monocoque wheelchair seat.

He used AutoCAD combined with NC Graphics Toolmaker to produce the first on-screen prototype. This was then machined, full size from a huge block of solid reinforced resin. The machining took three weeks and needed great care, as many sections were a fragile 4mm thick. Once this was successfully trial assembled, manufacture of the production moulds could begin. However, although he had originally envisaged the seat being made out of aluminium, this material proved to be very costly and as a result, he chose another very strong and more lightweight material – carbon fibre.

Down to the nuts and bolts

Using AutoCAD in conjunction with NC Graphics’ Machining Strategist, Spindle created a variety of tool paths for the more complex geometries of the wheelchair design. However, another rather unconventional ‘design tool’ he made use of during the process was his son’s Meccano set. Meccano is a model construction kit comprising re-usable metal strips, plates, angle girders, wheels, axles and gears, with nuts and bolts to connect the pieces enabling the user to build working models of, for instance, planes and trains.

“Some of the linkages on the wheelchair were quite complex and even with a pen and paper or CAD I wasn’t actually sure whether they would work the way that I thought they would. So, I used the Meccano set to prove that they would,” reveals Spindle. “Sometimes you stumble upon what would appear to be a truly new solution. An example would be the self-locking trapezium that forms the basis for our ‘varicam’ mechanism. I was almost sure it would work and the theory looked flawless however, there was no prior art and I just couldn’t believe the solution was so simple and so elegant. The Meccano model proved what is now the subject of a worldwide patent.”

Although the development proved to be a long and difficult road for Spindle it was one he was determined to stay on despite having to keep creating new prototypes and then going back to the drawing board again when they weren’t quite right.

“I never quite wished that we hadn’t started but it was very difficult because when you are breaking new ground there is nobody to ask how it should be done – you have to come up with the solutions yourself. We spent £1,000s making a particular device that didn’t work and that happened many, many times,” says Spindle. But having committed the company’s resources to the project he wanted to at least get to a point where he could prove that either it could or couldn’t work.

“What I didn’t want to do is spend all this time, money and many years of my life to prove that this thing was viable and then just give up. I wasn’t prepared to give up before somebody proved that it was useless. So, I felt compelled to find a solution to the problem,” he reveals. “Also, throughout the whole journey I always believed the solutions were already there, I just had to uncover them.”

Off the beaten track

In 2003, having overcome many complex engineering challenges, he had created a solution, in fact prototype number nine, that he was happy with. He took it to Aspire Leisure Services in Stanmore, Middlesex, a fully integrated training centre for disabled and non-disabled people, where he informally showed it to a focus group of doctors, nurses and wheelchair users. This exercise showed up one of the great strengths of the design – its off-road ability.

“We didn’t know at the time but because we had put the wheels at the front, the chair was quite good on gravel, snow and uneven surfaces. We had no idea that the average wheelchair was completely hopeless off-road as the little front castors get jammed,” says Spindle. “So, we realised that we had really hit on something here.”

Trekinetic has its own large 3-axis Haas CNC machine in-house

One wheelchair user in particular, Robin Gibbons, a former Royal Navy diver and ex-pilot, really helped in giving a critical assessment of the product and continued to provide valuable feedback over the remaining three years of the chair’s development.

It was Gibbons who pointed out that the three-wheel prototypes had poor directional stability and were unsteady at speed. As a result, Spindle developed a mechanism that automatically locks the rear castor into the straight-ahead position when travelling in a straight line and releases it when the wheelchair is turned. He also realised that in order to make the chair more stable the wheels would need to be tilted inwards because the wider they are at the point where they contact the ground the more stable the chair would be. But having the chair permanently wide would then mean that it wouldn’t be able to get through doorways.

The solution was an innovative ‘varicam’ system – by simply turning a rotating cross-shaft under the seat the user could easily change the angles of the wheels. So, at zero camber the chair is 710mm wide and then when adjusted to negative camber of 24 degrees it becomes 870mm wide. An adjustable nitrogen gas filled, shock absorber was also integrated into the design allowing the seat angle to be adjusted. In the end, Spindle filed for half a dozen separate international patents.

Nearing the end of the road

After the fourteenth prototype he was finally happy with his creation and had it tested to British and European standards by an independent body, the MHRA. In April 2006, the tooling was ordered, just in time for the Mobility Road show exhibition in June 2006. The response at the show was largely positive and subsequent press from the BBC, CNN and national newspapers including The Independent caused heavy traffic on the website as well as many emails and phone calls to Spindle. However, the interest did not only come from wheelchair users or companies interested in the commercial possibilities – many were from architects, engineers and designers who appreciated the design aesthetic and detailed engineering.

The Trekinetic K2 went on to win the 2007 Frost & Sullivan European Product Innovation award in the field of rehabilitation wheelchairs, an award that recognised Trekinetic’s pioneering work in developing an innovatively stylish and ergonomically designed alternative to present wheelchairs, and was nominated for a series of other awards.

Mass production

The K2 All Terrain wheelchair is now in its third year of production and just in the past few months production has been moved to a bigger, purpose-built facility, which is just over 4,000 square feet.

“It is a brand new unit that we have designed specifically for Trekinetic production,” says Spindle. “We machine about 50 per cent in-house and subcontract the seat moulding and some of the components. In fact, we are probably keeping a lot of small firms going at the moment. For instance, the wheels are specialised and they are made in the UK but we have had to now order 100 at a time to keep it all viable for a small company.” This production set-up can handle 20 chairs a week.

Assembly area for the all terrain wheelchair

The wheelchairs are distributed through a network of carefully selected dealers that currently consists of 11 in the UK, Belgium, Greece, Israel the Netherlands and Australia. “We have a good relationship with our dealers and more and more are opening up as time goes by,” says Spindle. As for marketing the product, Trekinetic relies predominantly on word of mouth with many of the users doing their own ‘advertising’ by using their wheelchairs off-road such as in the country or on the beach, drawing admiring glances from both disabled and able-bodied people.

“Because the chair is so unusual our users get stopped in the street and asked where they bought it from. Only this week I got a call from somebody in Dubai who actually saw someone using the wheelchair in Dubai and wanted to know how they could order one,” says Spindle.

However, not one to rest on his laurels and bask in the current success of the K2, Spindle claims that he has a number of “groundbreaking” ideas up his sleeve that he wants to introduce to the mobility sector in the next three years. One of them he reveals is an electronically powered version of the wheelchair, but the second he guarantees will take everyone by surprise. “It will be based on this chair but I don’t think anybody expects what we are going to do next,” he says. So, without it sounding like too much of a cliché, watch this space!

20 ways F1 racing is changing our world

F1 racing isn’t just about fast cars and tight boiler suits. The Trekinetic K2 All Terrain is currently featured at an exhibition at London’s Science Museum, which showcases 20 examples of where F1 technology is impacting on our lives. The F1-inspired wheelchair will be showcased alongside examples of new ways to look after patients, design sports equipment, and maintain heating systems in homes.

The exhibition runs until the 5th April 2010 and is FREE. Result!

www.sciencemuseum.org.uk

The Trekinetic K2 All Terrain isn’t your average wheelchair