Despite many of us having the need or desire to take on a project, finding space and the right equipment is what is holding the majority of us back.

Professional equipmentis available to members 9am till midnight, 7 days-a-week

In the modern world, traditional options have limitations: classes at schools involve long courses to attain qualifications and you’re limited to when you can use the machinery.

In an increasing culture of health and safety liability, workplaces rarely allow after-work projects.

For Jim Newton this was exactly the problem, so he decided to do something about it. In 2005 he arrived at the idea of a health club-style membership for a tool-equipped work space, where people could join as a member, and instead of working on exercise equipment would have access to all sorts of professional tools to make things.

“I wanted all the cool tools!” exclaims an upbeat Newton. “This was purely selfish – ‘ok, I’m going to let people use the shop so they can pay for it so I can have it for free!’ – that was the concept.”

Playground for creativity

From here on TechShop was founded – America’s finest playground for creativity where you can make virtually anything, using professional, full-scale equipment.

“You take the class, you get checked out, we show you how to use it and be safe, and then you can come in whenever you want and use the stuff,” adds Newton.

The first TechShop opened its doors in 2006 in Menlo Park, California and since then it has expanded to include six further shops across the US, with plans for three others to open soon.

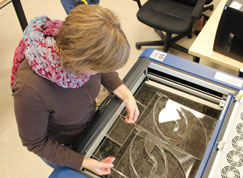

Each of the facilities is open from 9am to midnight, seven days a week, and offers laser cutters, plastics and electronics labs, a machine shop, a wood shop, a metal working shop, a textiles department, welding stations and a waterjet cutter.

Members have open access to design software, featuring the entire Autodesk Design Suite, as well as giant project areas with large worktables.

Helping hand

Autodesk has invested heavily into TechShop, both through funding and via the provision of software for all the labs and individual members, so they can install the software onto their own laptaps and use it there.

It also heavily subsidises the Autodesk Inventor classes for members to take.

“They’ve really gone all-in on support for this,” confirms Newton. “CAD in people’s minds is hard, it’s one of those big barricades that the average person would say there’s no way they could learn CAD to do my project.

“That’s not true; CAD software today is really very easy to use, very powerful, specially something like Inventor. It’s a very empowering tool in TechShop as there’s so many machines here that are CNC-driven, so CAD is really important.”

Set up shop

American automotive giant Ford has also partnered heavily with TechShop. Determined to provide facilities and boost innovation amongst its employees that form the heart of the community in the city of Detroit, US.

The company pre-purchased a set amount of memberships for their employees, giving Newton and his team the funding to open the latest branch.

Ford gives the memberships to its employees as part of its patent rewards program. As a result Ford’s submissions of new patents are up 30 per cent since they started the program.

“For Ford to get a 30 per cent boost in patents and maybe a few of those things end up on the line of cars, that’s huge for them – an enormous return on investment,” says Newton.

“The engineers that work at Ford aren’t allowed to come in after work into the workshop and make a go-cart, or a medical device idea that they want to sell. Once the five o’clock whistle goes you send all these super smart people home and their minds are still racing with ideas.

“This gives them an outlet, not only for Ford-based projects, but also for their own personal projects.”

Fittingly for ‘Motown’ the Detroit TechShop is complete with garage turntable and drive-on hydraulic ramps.

It’s also not solely for professionals; it’s a place where all different parts of the community can gain new skills or be inspired to try new things: there’s sewing machines for textiles classes; suites of Autodesk Mudbox for Sub-D modelling, and the staff are frighteningly enthusiastic and knowledgeable.

As a result of its successful partnerships TechShop is on the verge of the next level of expansion, with new partnerships and expansion to Europe all being mooted as possibilities for the future.

techshop.ws

TechShop provides the tools and the space to get the job done

Default