“Every day is a school day” is a common refrain among the DEVELOP3D team. Back in the workshop with some new hardware, Al Dean ponders the joy of learning and how it’s fundamental to engineering and design

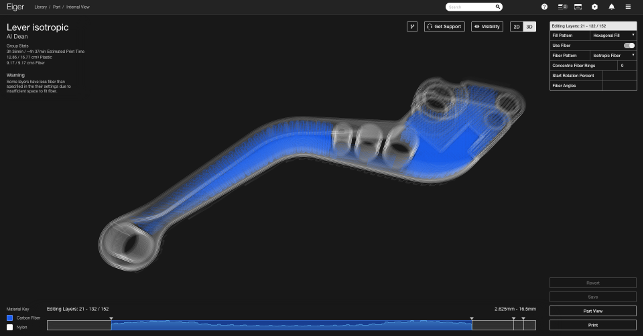

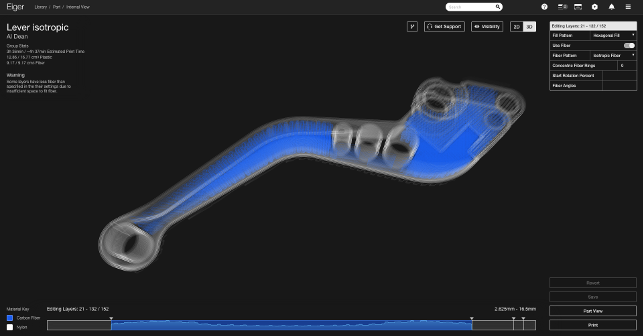

MarkForged’s cloud-based Eiger system gives you full control over how your parts are built

Earlier this month, I took delivery of a rather exciting package, once I’d filled out those painful forms that come with importing machinery from overseas.

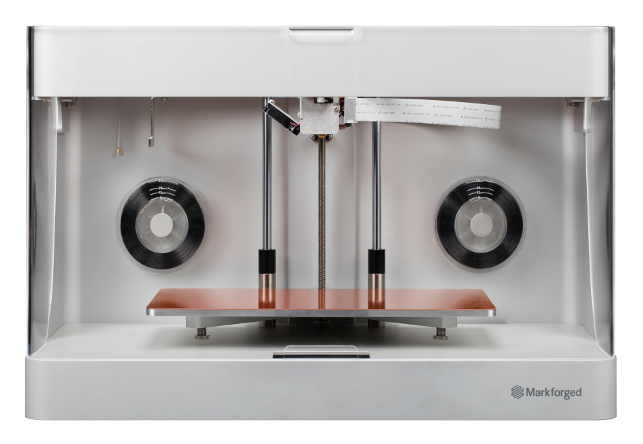

The team at MarkForged has sent us one of its rather miraculous 3D printers. In fact, it’s one of the first production units of MarkForged’s Mark II machine.

If you’ve not come across these 3D printers before, they’re built on the same core principle as many fused deposition machines. A part is built up layer by layer by depositing filament, in this case, nylon.

What makes the MarkForged machine different is that alongside the standard filament, it can also layer down fibre reinforcement, in the form of glass, kevlar or carbon fibre.

What’s interesting is that the Eiger software that goes alongside the machine isn’t the usual pre-baked, wizard-driven software you might have come across with other systems. Instead, it gives you full control over the process, build control, fibre deposition, fill pattern and density, on a layer-by-layer basis.

Of course, as I’m discovering, if you want to use the automatic settings, you can get a reasonable result (it tends towards sandwich panel construction, with a couple of layers of fibre at the top and bottom of the part), but if you want to make the most of the hardware’s capabilities, you need to dig into the settings, learn the ins and outs and get manual on this bad boy.

The Mark Two from MarkForged boasts an aluminium chassis and a level of engineering that’s not only impressive, but also unbelievable, at this price

The thing is that it’s been a long time since I’ve done anything in the composites arena and an even longer time since I took those fundamental classes at university.

So I’ve been hitting the books after finding a bunch of textbooks second hand on the Internet. And it’s been a joy. It’s always good to exercise those parts of your brain that have been dormant for a while.

But why all the research? The answer is pretty simple. There’s no point in working with a bit of hardware that’s been carefully concieved, developed, engineered and refined by the MarkForged team, if I’m building parts purely for the sake of it.

That’s just wasteful and not particularly useful for those who read the eventual review (we’re shooting in May). If you want a rundown of how long it takes to print Yoda’s head, then you’re reading the wrong magazine.

But you know what? It’s been an interesting week so far and I suspect that’s going to continue to be so for a good long while.

There’s so much potential in this machine, for both building prototypes that are more functional as well as for final-use components, that I can’t help but get excited and eat up the information.

After all, that’s what those with an involvement in design and engineering do: find a problem, learn all they can around the subject, combine it with existing knowledge and some smart thinking and solve it.

Design and engineering aren’t jobs that people take lightly and it’s not just training.

It’s more fundamental than that. It’s a passion – and it’s one that needs feeding. And that’s why learning, as they say, is earning.

Al Dean ponders the joy of learning and its role in engineering and design

Default