If there’s a single question I’ve been asked most often in the last year, it’s ‘Can you explain Dassault Systèmes’ 3DExperience?’

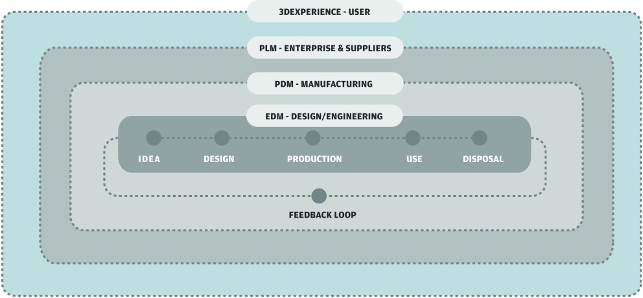

An interesting way to think about a product’s lifecycle

With Dassault Systèmes’ (DS) long-standing customers – the Boeings, the Fords, the BMWs of the world – who have evolved with the company over a number of years, the concept of 3DExperience is easier to grasp. But for DS SolidWorks customers, who are being presented with the vision at corporate events like SolidWorks World, it has caused a lot of confusion and, in some cases, concern.

In short, 3DExperience is the next big goal in the DS roadmap and represents the next step on from product lifecycle management (PLM).But what exactly is it?

A 3D what?

DS launched its 3DExperience concept in 2012.

To take the corporate line, it “transforms the way innovators will innovate with consumers by connecting designers, engineers, marketing managers and even consumers, in a new ‘social enterprise’.”

From this one sentence it’s possible to extrapolate what DS is talking about. But when I hear the expanded version, there’s all manner of things that simply don’t make sense. Or at least, make me feel rather stupid for not understanding them.

Here’s a perfect example, taken from CEO Bernard Charles’ keynote at the Korean 3DExperience conference in May 2012: “The virtual world extends and improves the real world. We have formulated a dream. I think it’s also very important in every company to have a dream. It gives some freedom.

It removes the limits of the daily constraints. And when you are lost, in any companies, you come back to what is your dream.

“You need a dream in your life, you need a dream in your family, you need a dream for any companies on any social structure. And our dream when it comes to Dassault Systèmes is to help through the usage of universe, 3DExperience universe to harmonise product, nature, and life. It’s a very ambitious dream.”

To be frank, it’s all a bit too abstract for me. But luckily I got some time with Pascal Daloz, DS’ executive vice president of strategy and marketing.

I began by asking him to define the difference between the company’s V5 and V6.

According to him, “V5 is a technology. It’s not a value proposal. What’s the purpose of this technology? It’s a client/server technology with Windows as the client. V6 is still a web-based technology with Java as the client. This is the difference.” So far so good, but things started to get interesting when Daloz explained the difference between PLM and 3DExperience.

“PLM is basically nothing more than a Digital Mock Up (DMU), but from ideas to the products to the operations. The people you are connecting with this DMU are only the professional ones. The people being part of the development cycle. The extended enterprise and professionals,” he explains.

“With 3DExperience, what we want is to connect the consumer into the cycle. Not only at the beginning of the process, focus groups, and at the end of the process to do the testing of the product, but at each major step.”

Now this is an interesting idea. Over the last few years, there have been huge changes in how those outside of the design department are involved in the design process – it is not done alone anymore. But how does DS define ‘consumer’ when most of the work its customers do is outside of the traditional consumer goods market?

DS perceives a ‘consumer’ as the ‘person that uses the end product’ which isn’t necessarily the same person that buys the product. If the product is a pair of spectacles, it’s the person wearing them not the optician. If it’s a forklift truck, it’s the operator, not the purchasing manager at the warehousing company. If it’s a BMW car, it’s the driver, not the dealer or fleet manager.

A case in point

In a meeting with Proctor and Gamble (P&G), Daloz discovered there is a huge delay in the product development process because of consumer testing and the need to feed the findings back to the design department.

“They were spending more time developing this bottle of shampoo, a simple bottle of shampoo, than BMW to develop an entire car.”

The seemingly simple process of designing a container for shampoo needed consumer testing at almost every stage. Not just in terms of its shape, but labelling, colour and artwork too.

With each decision, P&G conducted consumer focus group testing. This meant either building a custom shop or taking over a shelf in a range of existing outlets. It also meant stocking it with products, both its own and those of its competitors, testing different options and configurations. All of this was being done across the globe in a 48-month cycle. We’re not talking about the chemical formula for shampoo, but the bottle it goes into.

When you consider that P&G has, according to Daloz, 200 manufacturing facilities across the globe, a policy of ‘single product, everywhere’, it’s clear that things need to be right before committing resources to production.

So how did this conversation change DS’ perspective? “This anecdote opened our eyes,” admits Daloz. “We thought maybe there are a lot of industries having this problem. “We thought maybe this is the time for us to investigate if we can connect the consumer at the different stages.

At the same time, we’re going to develop the products and the story related to the marketing message attached to the products. But we’re going to have feedback loops before and it’ll be an iterative system.

“The first time I met the [P&G] CTO he said ‘I want to digitalise from the formula to the shelf’. It was his statement and now I understand why. To come back to your question, this is what 3DExperience is all about. The rest is… marketing.”

What does it actually mean?

Abstract marketing messages and anecdotes about meetings with very large companies are one thing, but what we really need is a clearer picture of what DS is up to, how it will manifest itself in not only the products, but also how they’re pitched and used.

These days, the future of DS’ work not only affects users of Catia, Enovia and Simulia, but also those in the SolidWorks community. With plans already underway to develop SolidWorks on the V6 platform this has never been more relevant .

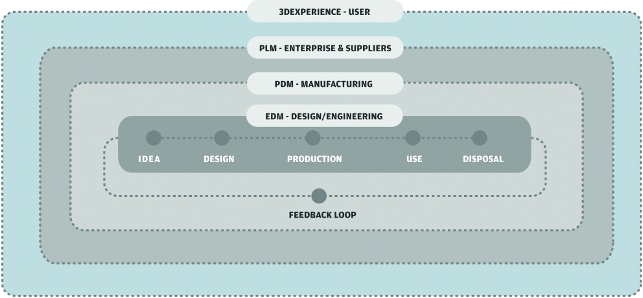

Let’s start with a breakdown of what 3DExperience means in comparison to the world of PLM.

In my opinion, at its very core, PLM means the use of a technology solution that allows those involved in product development to contribute and engage in the process – from conception through to disposal. It allows those in marketing, purchasing, manufacturing, process planning (everyone essentially) to be active and provide their guidance in the process.

PLM is also about feedback loops. If a product’s lifecycle can be captured, from the earliest point of requirements capture, conceptualisation, engineering, production, servicing and finally disposal, then you have a baseline of data on which to iterate the next generation of product, learn from your mistakes and improve the next project.

The important thing to note is that PLM is about those directly involved in the development of the product: the professionals, those within a single organisation or in a supply chain environment.

Where 3DExperience differs is in the idea that there’s huge benefit to be gained in gathering consumer feedback at all stages of the product’s lifecycle. This is something that’s typically not done in industry and certainly not done in the context of any of the business systems used in the design to manufacture process.

While I think we’ve got a good handle of the what and why, now it’s time to look at the how.

There are three key technology parts to this story and they’re all worth exploring in detail as they show how DS is looking to turn 3DExperience from a high-level concept to a deliverable product that can bring the consumer ‘into’ the product lifecycle.

#1 Social analytics and Netvibes

Many have been trying to work out why DS acquired Netvibes a couple of years ago.

If you read the corporate spiel, it’s “an internet platform that delivers a holistic snapshot of any key information related to my company or my personal interest.”

Social internet platform? This doesn’t exactly mesh with DS’ corporate activities does it? But, considered in the context of 3DExperience, think of it like this: today’s consumers increasingly express themselves digitally.

Whether it’s a snarky comment on Facebook shared among friends, a rant on Twitter about bad service or a product review on Amazon. What Netvibes does is aggregate that information into a single dashboard.

For the individual, this might be an interesting diversion – after all, who hasn’t Googled their own name? However, for corporations it’s a whole different kettle of fish: If you have a mechanism to collect all information relating to your brand, your company, your specific products, globally, across the social media spectrum, then you have a huge quantity of data and opinions.

Taken individually, these might not make much sense or give guidance to the product development process, but taken at a higher-level, one can see trends, issues, good and bad views – at a glance.

At the recent Product Innovation Congress in Berlin, I heard at least two companies (Unilever among them, for an idea of scale), talking about the wealth of data available to help with product development decisions. What do people like? What do people hate? Taken with a pinch of salt, and some clever analysis, this can be valuable information for those developing next generation products.

Another example is a discussion with a well-known floor care equipment manufacturer (no, not THAT one). It released a lightweight product onto the market. The reduced mass, in particular, was meant to allow the owner to clean stair carpets easily.

After release, the company saw a string of comments from customers on Amazon saying that both the nozzle hose and the power cable were too short. Obviously this was done to save mass, but for the customer, it was a pain in the backside.

Traditionally, this wouldn’t have been discovered for months, if at all. Customers wouldn’t complain directly.

They might have returned the unit and never bought the brand again. But with this insight, the company in question quickly reiterated the design, factored in a longer hosing and cable and gained sales as a result.

Netvibes’ raison d’être is to bring all of this information into a single dashboard, present it in a meaningful way and allow decisions to be made from it – or at least to discover where issues or benefits lie.

DS is building up a system whereby this information is captured and made available to everyone in the product design and development process. Not in a separate system, but in the same tools that are used to take a product to market and manage its lifecycle.

If you then consider that data can also be captured for competitive products, then you’ve got something really interesting.

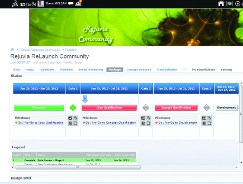

#2 Connecting the wider team & 3DSwYm

If you look at the target market for this type of technology stack, there are a couple of interesting elements in terms of the teams who are not directly involved in product development.

In the large-scale consumer goods manufacturing world, there’s the product fulfilment team and those that are involved in sales and retail. These are the people on the streets selling the product – whatever it might be.

For example, DS has a customer called Mikli. You might have come across its iconic Shutter Shades at some point, even, God forbid, watching a Kanye West video.

This organisation has a couple of business activities. An eyewear design house with its own brands and others.

Mikli Spectacles are a highly personal product and getting it right is a combination of thinking outside the box to generate new concepts and designs, and tailoring those to trends, global or regional. What’s interesting about Mikli is that it is also in the retail business, again, operating globally.

The challenge that the company has is designing products that push the boundaries in a high value, luxury goods market, while also ensuring that there’s commercial success.

To connect the sales and retail team with the design team it needs a centralised system to track stocking levels, popularity as well as providing a mechanism for everyone involved to provide thoughts, commentary and input that the design team can factor into their process.

This isn’t a case of design by committee, but if there’s a product that’s not selling, it’s clear that the design isn’t working and that needs to be taken account of in planning the next range.

Typically this information would be spread across multiple departments and multiple systems.

Connecting this all up makes sense and is what DS’ 3DSwYm, the online service dedicated to the management of online professional communities, is purposed to do.

#3 Consumer testing & the digital shelf

This relates directly back to Daloz’s story about the challenges that P&G face on a global scale to capture consumer feedback more quickly than the traditional process of consumer testing and focus groups.

If the companies involved can use digital processes to connect with consumers, enable them to experience multiple variants of a product’s form, in context and in a familiar surrounding (e.g. a shop shelf), all in a digital environment, this can lead to serious cost savings.

To start, prototype production costs are significantly reduced as no one has to make and ship prototype units.

Costs are also saved in management of the testing as it can be done from home or at least a kiosk. Yet, perhaps as importantly, the data (such as what works, what doesn’t work and the context) is available immediately and can be factored into the design process in a much more efficient manner.

DS is building out exactly this capability with its Perfect Shelf initiative. Companies can build immersive point of sale environments, which allow the consumer interaction as normal, but also enable metrics to be grabbed out of the process in an instant.

Consider the multiple variants at play here. Not only are there variables pertaining to the product in question, but also regional differences in shopping experiences, varied shelving and display strategies and different arrangements of competitor products.

Disruption through confusion?

Personally speaking, I find all of the above intriguing. Yes, the tools aren’t for everyone and it would take a much larger company than most to not only adopt them, but also afford them.

That said, there are elements that could be adopted by a much wider audience as and when appropriate.

The point is that 3DExperience, when considered like this, is an entirely valid approach. What I don’t understand is why DS seems unable to communicate this clearly.

When challenged about this, Daloz was open and frank, “You know Bernard, the way he behaves. He’s pushing ideas and then he lets the market adopt the ideas and define the limit of those ideas.

This is the reason why he doesn’t want us too limit it in the way we define it. “We want this to be open and let the market define what 3DExperience is about. But from a pure technology standpoint, this is what it’s all about.”

At the heart of this is how DS wants to be perceived as a company and its position in the market, as Daloz explains, “If you want to change the market boundaries, confusion sometimes helps, because the worst that can happen is that you get put in a box: You are CAD tools, you are PLM.

“For example, all the customer relationship management stuff goes into the Salesforce box. But why can’t we have some customer inputs in our systems, why does it have to be in Salesforce?

“The answer is because Salesforce created a customer relationship box and everything goes into that. I don’t care, let’s call it ‘Experience’ and it’s everything.”

When challenged, that perhaps DS simply doesn’t want people to know what it does, the response was the infamous Gallic shrug which, while never entirely clear in its intent, I took to be a confirmation.

When asked if DS is one of those big companies that does everything, the waters started to clear somewhat, “When you want to create disruption in the market, you should allow the market to define it,” said Daloz. “The real proof will come from the customer who will have this technology running, with results. They will tell us what they can do and what they can’t do.”

Conclusion

So, to conclude – it would appear that 3DExperience is a perfectly valid idea and solution set, particularly for larger firms. But it appears that DS is purposefully obscuring exactly what it does so that it doesn’t become pigeon-holed as a provider of a specific set of tools.

I can understand the logic behind it, but the problem is that the company is in danger of alienating its more traditional customers.

DS SolidWorks users seem particularly, and rightly, confused, at a critical point in time when the product that they’ve used for many years is starting to make the transition to the DS V6 platform.

The thing is, I’m not entirely sure that, even if explained more clearly, the concept of 3DExperience would interest most of the SolidWorks community.

Yes, there are some huge multinationals that use SolidWorks as their main design system and these might be the perfect target for some of these types of technologies and product sets. And they might be able to afford them.

However, for the rest of the design and engineering firms that are used to hearing about SolidWorks in terms of its new modelling features, the ‘big vision’ messaging that is being used to explain 3DExperience may be a step too far.

3DExperience is a huge investment, both financially and in terms of training staff, working with suppliers and clients and a back catalogue of work and data: If companies can’t easily learn about the future of those tools, then they start to wonder what to do next.

I’m used to DS’ marketing being more than a little bit removed from reality, but I personally think that it needs to start explaining more clearly what it’s planning and where its roadmap is heading.

This can only happen concurrently with its plans for the future of its core product, in terms of profitability, SolidWorks. Without those two things happening at the same time, then all the roadmap PowerPoints presentations we see at DS events and conferences won’t help.

What does Dassault Systèmes mean by ‘3DExperience’?

Default