King among men

After leaving Portsmouth University with a degree in engineering, King of Shaves (KOS) founder Will King found himself designing a new razor back in 2003.

Having had lots of influences – from the flex of a toothbrush head, to a piano tuning fork – he spent hours sketching and constructing prototypes, and seeking out a blade provider. The end product was the Azor launched five years later.

However the story has continued and the design has evolved further with the Azor 5 for sensitive skin.

Featuring an improved soft-flex hinge in its distinctive handle to follow face contours and a larger skin pre-tensioner to stretch skin before the blades pass over it, it aims to reduce cuts and grazes while giving a close shave.

After some initial concept sketching to evolve the original Azor, the in-house design team at KOS moved straight into Siemens NX to work with the 3D CAD model. The way a razor balances and feels in the hand is crucial, so the designs are prototyped from an early stage.

Using print bureau OPS’ Objet Connex 260, the models have tactility, flex in the right places, and show the distinctive twoway materials difference. When designs are finalised, the team use Proto Labs to produce CNC prototypes in the correct materials for testing.

The final product was brought to market much faster than its predecessor, shaving countless days off its development time through use of 3D design tools.

Mother plucker

Combining tools has always been a good way to simplify design and save time. It worked for the Swiss Army Knife, so why not beauty products?

The BeautyBit concept was conceived when its creator Dawn Sole found herself searching around her handbag for three different tools – a nail file, buffer and pair of tweezers – when she imagined they could be combined.

With her business partner she took this idea to Innovate3D, a product design agency based in Detroit and, using conference calls and CAD viewer technology from her home in Miami, helped to develop the final product.

The product was designed in SolidWorks, incorporating slanted tip stainless steel tweezers with a removable (and therefore replaceable) nail file and separate buffer.

“The most difficult elements related to the fact that tweezers are flexible and need to move,” explains Innovate3D invention engineer Kenan Wollborg. “We dealt with this by designing the BeautyBit product in both the closed and opened positions, and then designed the final CAD models using a hybrid of the two different model states.”

The product was 3D printed early in the product development cycle to help the inventor close the loop between CAD images and functional elements.

The idea has already won awards, and is now getting ready for production thanks to being brought to life by Innovate3D.

Smooth operator

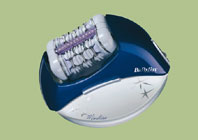

With motorised, multi-headed tweezers, epilators remove hair by mechanically grasping multiple hairs simultaneously and pulling them out.

The design of BaByliss’ range is aesthetically driven and products look to fit in with similar beauty products and the rest of the company’s global product line.

Technical design also plays a major role, including head speeds, noise levels and waterproofing, all for which the engineering capabilities of PTC Creo are utilised.

Two ultra-thin, reverse rotation depilation heads are used to remove the hairs as painlessly as possible, activating 30 sets of tweezers at 2,000RPM.

Its European design team works with PTC Creo to match the rest of its global design teams, allowing for easier collaboration between designers, stylists and engineers from the concept phase through to final design.

Stephen Holmes gets to grip with the latest shaving tools

Default