The design of gas burners for cooktops is challenging because of the many design parameters involved.

How well a burner will perform depends on the geometry of the port where the flame is produced, the injectors that provide gas and air to the ports and the grates that support the ports, as well as the relationship between the ports and the metal surface of the appliance.

Whirlpool Brazil relies heavily on simulation to design gas burners for freestanding ranges, built-in ovens and cooktops. Simulation helps engineers not only to reduce fuel consumption and cooking times, but also their own development times, by predicting the performance of proposed burner designs ahead of the prototype phase.

Whirlpool’s engineers use Ansys computational fluid dynamics (CFD) software to evaluate proposed burner designs for flame stability, energy efficiency, surface temperature and carbon monoxide generation.

However, they also required a tool that would enable them to prepare models for simulation, so that they could quickly explore a range of designs and come up with the best burner to meet all criteria.

Whirlpool overcame this challenge by using Ansys SpaceClaim Direct Modeler, which allows easy geometry clean up and generation of closed volumes required for CFD simulation.

With the SpaceClaim approach, Whirlpool engineers can directly edit any geometry feature without worrying about parametric constraints, reducing the time required to prepare a concept design for analysis by up to 90%.

The ability to much more quickly define and evaluate new design iterations has reduced the overall time required to develop a new cooktop model by 30% to 40%.

Streamlining the design process

Whirlpool engineers had been creating burner designs using a parametric CAD system.

CAD systems generate the highly detailed models that are vital to meeting rigorous manufacturing requirements – one of the final steps in the design cycle.

However, early in the design phase, engineers needed a tool that allowed them to make multiple design interactions easily. They could then virtually test these designs using simulation.

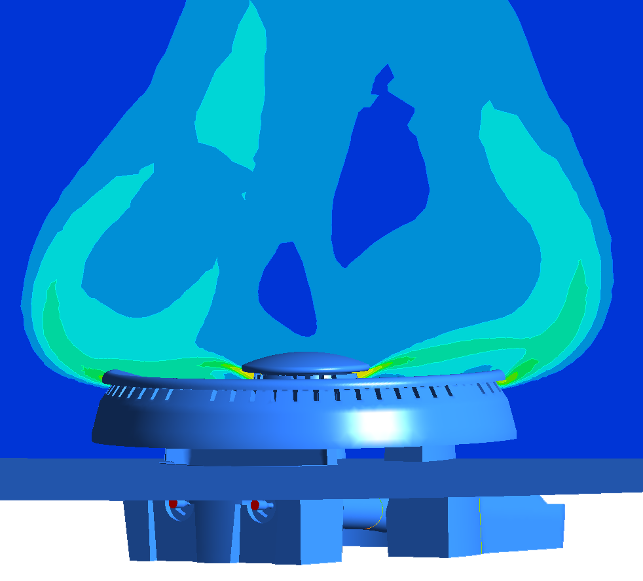

Simulation of new burner design. Simulation was conducted to study air/fuel ratio at different locations inside and outside the gas burner. The image shows natural gas concentration on a cross section of the burner

A single CAD model took a week to prepare, and at least 100 days were required to complete a new burner design.

Integration of Ansys SpaceClaim Direct Modeler within Ansys Workbench enables engineers to make and investigate design modifications in a fraction of the time required in the past.

Whirlpool Brazil engineers used these tools recently to design a new cooktop for the consumer market. Engineers first created a baseline design using the company’s parametric CAD system. Then they stripped out the parametric constraints by exporting a STEP file into the Ansys Workbench design environment.

SpaceClaim Direct Modeler’s advantage is that it uses pattern recognition on an imported model to determine the user’s intention when making an edit, so the model can be manipulated as if it were fully parametric.

For example, even though a pocket has not been defined as a feature, the user can select it and the software will recognise, in real time, that it is a feature and then allow the user to change its size or move it without breaking it down into its individual entities, such as lines and arcs.

Put into practice

In the case of the cooktop burners, Whirlpool Brazil engineers began by using a SpaceClaim tool that automatically finds and fixes gaps and overlaps between the surfaces of the model.

This tool addressed the majority of the problems with the original model. Engineers then corrected additional areas using other SpaceClaim tools, such as one that cleans up small features and fills holes.

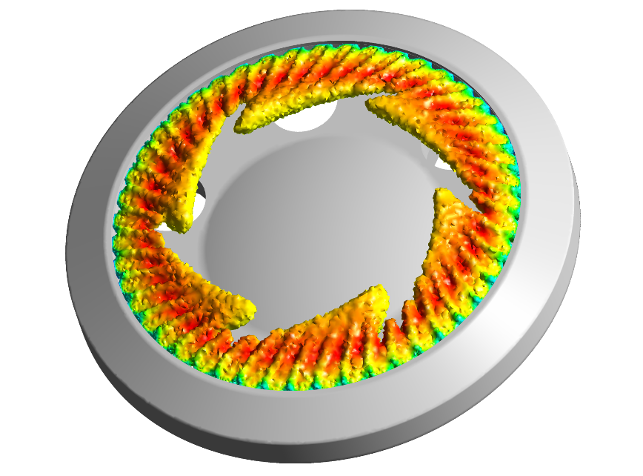

Iso-volume of percentage of fuel with temperature plot

Further edits were made simply by selecting faces and edges and pulling or moving them into the right position.

The model was ready for meshing and simulation in just four hours. The mesh had 2.5 million nodes and 10.2 million tetrahedral, hexahedral, wedge and pyramid elements.

Whirlpool engineers ran an Ansys Fluent CFD combustion simulation using the EDC combustion model and SST turbulence model. The simulation took 36 hours to run on a high performance computing (HPC) platform with 20 cores.

Results showed the mass flow of fuel and primary air, carbon monoxide concentration and surface temperatures on the cooktop.

Whirlpool Brazil engineers also wrote a script to calculate burner efficiency. The simulation revealed significant areas for improvement in the initial design.

In total, Whirlpool’s engineers generated a total of 16 iterations with SpaceClaim to investigate changes in port and injector geometry. They focused on increasing the primary air entrainment, a measure of how effectively air is taken up by the burner during operation, expressed as a percentage of stoichiometric supply.

Over the course of these design iterations, engineers increased primary air entrainment from 36% to 52%. This delivers a stable flame with nearly complete combustion, high levels of efficiency and low levels of carbon monoxide.

The complete design process took about 65 days, 35% less time than would have been required using previous methods.

This application demonstrates the time- and cost-savings that can be achieved by enabling simulation engineers to quickly and easily prepare design geometry for simulation, as well as how an efficient design can be determined using simulation.

Ansys’ simulation tools help Whirlpool build a better burner

Default