3D printing again. Yes, I know. But this is an important one as it may change how we interact with these 3D printing systems especially as we are using them to print ever more complex forms.

Science crosses over into art

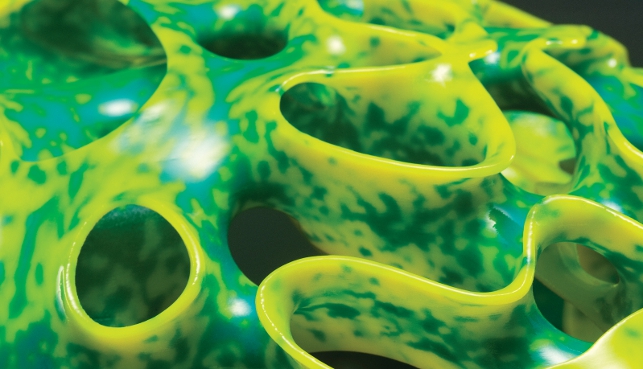

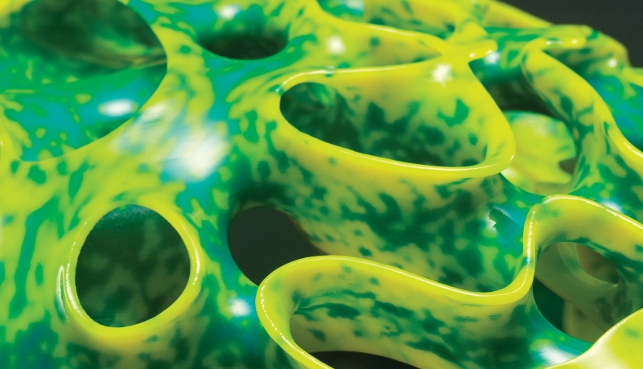

Take medical implants with their lattice structures that interface with living bone or artistic sculptures with their intricate, multi-material forms.

The 3D printers on which these objects are built are highly advanced and as such need a more advanced file format than what the traditional Stereolithography (STL) format can offer. Enter the Additive Manufacturing File (AMF) format. Like STL, AMF is used to describe the shape and composition of a 3D object for fabrication on any 3D printer.

The big difference, however, is in the level of detail built into the format. If STL is an approximation of CAD geometry, think of AMF of a more accurate real world representation of a 3D print ready model, with colour, materials and complex geometry built in.

But before we get into why AMF is better, let’s first look at what we currently have with STL.

The limitations of STL

Developed by 3D Systems in 1987 and opened up in an uncharacteristic show of charity, the STL format takes your nice, clean CAD geometry and tessellates it into a triangularbased polygon mesh.

That mesh is then taken by the host software and sliced at increments that match the build process. Each slice is then sent to the 3D printing machine and built, one on top of each other.

This much we all know but the problem is that the mesh is a complex thing – not in terms of the geometry it holds, but the way in which it’s generated. The essential task that the STL performs is to break down the form of the part into a lowest common denominator so that it can be communicated to the build software.

Each CAD system controls how this is done in different ways, but usually the user has control over how the mesh deconstructs curved forms.

As it’s essentially an approximation of the CAD geometry, it’s not an ideal situation. This may have been fine when the STL format was born 25 years ago, when there was a need to lower the resolution of files so that the computers of the time could cope, but in today’s environment this seems arcane and ridiculous.

That said, the STL has stuck around and it’s been the de facto standard for two decades.

Additive manufacturing format-STL 2.0

Although the STL is old, creaky and basic, with the right settings it can work. Is it ideal?

No, not on yours or anyone else’s nelly and although we won’t get into the nitty gritty of how AMF works, here are the basics as to why it’s better:

Curved surfaces: This is a big one. Rather than rely on planar triangular facts, the AMF format gives a method to create ‘curved triangles’. While the mathematics is beyond my meagre understanding, the AMF format holds curvature values for each edge of a facet.

When it comes to processing for manufacture, those values are then used to further decimate the facet and create a much closer representation of the form, certainly when dealing with layer-based processes it’ll be unnoticeable.

Units: STLs are unit agnostic. To ensure that you’re building a component to the correct scale, you need to know what units the system has output the file in.

While the difference between millimetres and inches is pretty obvious when you read in the part (it’ll either be tiny or massive if you get it wrong), there can be issues with less standard units. For instance, I personally had an issue with Inventor as it defaulted to outputting parts in centimetres.

Unless you’re aware of that, it can cause some serious problems downstream. But AMF could safeguard against it if implemented correctly.

Colour & Texture maps: STLs don’t represent colour. There have been a few initiatives to add colour specifications into the STL format, but perhaps the most widely used colourcapable format is Z Corporation’s ZGL format, which is supported in quite a few systems.

With AMF, colour values (RGB + transparency) can be applied to material, object, volume, vertex or triangles. There’s also some support for texture mapping at a low level.

Material specification: This is a big one considering that multi-material 3D printers, such as Objet’s Connex machines, are coming on stream. Being able to define the material characteristics will be key.

Lattices, matrices & constellations: This is where the AMF might score big in specific markets, such as medical, where some forms are simply impractical to represent with old-school STL.

The AMF format includes the ability to both arrange multiple instances of an object or an assortment simply and easily. For those working with lattice, matrix driven geometries, this is going to be a massive benefit.

Catch 22: Demand vs supply

So, we’ve established that STL isn’t ideal, but works.

We’ve also established that the nascent AMF format could provide better support for today’s 3D printing processes and advanced users’ requirements. But will anyone actually support it?

Software vendors

From my discussions, some vendors are aware of the format but are reluctant to commit their support.

A good example is PTC, whose vice president of Creo product management, Brian Thompson, states, “We can see how the additive manufacturing market would want this format– it seems to be a useful replacement of a pretty old STL standard.

We don’t have any official plans to support it in the coming release of Creo [Creo 3.0] as there hasn’t been any demand.

We will continue to work with our customers and partners to determine how much of a priority support of this format is, so we can factor that into future product plans.”

SolidWorks was similarly reluctant to commit. “We aren’t getting customer requests for this as it’s being driven by the printing industry. We have not had any vendors come to us about supporting this. When it’s well defined and there are machines that support it we will determine a timeline to support it.”

It seems that many of the other CAD software vendors are taking a similar ‘wait and see’ approach. The only one with any enthusiasm about its potential is Autodesk, which is a pretty obvious candidate considering it’s already established links with the 3D printing and maker market.

Autodesk’s director of consumer products, Thomas Heermann, says “Autodesk believes AMF provides a richer data pathway between design and 3D printing, and we intend to support the standard moving forward.

We are also actively collaborating with several 3D printing manufacturers with the goal of continuing to improve the 3D printing experience from within our software. In addition to STL, OBJ is a current industry standard that also works for fabrication/3D printing.

It is a mesh type as well but can also have associated colour information.”

Machine vendors

Of course, CAD is just one element of the equation.

The machine vendors also need to be onboard as they have to add support into their pre-processing software. So, I asked a few of them to get their perspective.

Stratasys’s vice president of engineering, Dick Anderson was verbose on the subject, again raising the spectre of the need for all parties involved in the process to add support.

“The new AMF format offers significant customer benefits that will be realised after implementation in both CAD and additive manufacturing software, and Stratasys will start AMF support in 2013.

The benefits in the transition from STL to AMF include more accurate descriptions of 3D geometry and additional process attributes.”

Objet did not have much to say on the subject other than the fact that it’s “committed to support AMF in the future.”

According Dr. Ofer Shochet, executive vice president of products at Objet, the company cannot provide timeline for future releases, though work is under way.

Service providers

I also asked a couple of the online service providers because, after all, the majority of 3D printing is done through outsourced services, so if this format is truly going to take off, service providers need to be onboard.

While for those that run in the traditional business model of taking customer data through email or upload, the inclusion of the format from CAD vendors will suffice, but for the new

breed of vendors, this will no doubt be a requirement.

To get a feel for things I asked two of the current leaders in the field, ShapeWays and Materialise.

ShapeWays can see the potential but has concerns over some of the more intricate details of the format. Alan Hudson, director of 3D tools at ShapeWays, explains “Following the specification closely we’ll be interested to support this format as more compliant technologies emerge on the market.

In terms of detractors, the addition of a conformance suite would help adoption as some of the features are not widely supported.

For example, there is a concern that some of AMF’s features such as curved triangles and material formulas may not map well to existing technologies.”

Meanwhile, Materialise has even more to gain from adoption.

In fact, it has had AMF support in its Magics software for a little while and actually two of its technical staff, Kurt Renap (principal software architect) and Karel Brans (research project manager) have been heavily involved in AMF’s development, as a Materialise spokesperson explains, “The AMF format was developed by the Design Subcommittee of the ASTM F42 group for AM standards.

Materialise is vice chair of this subcommittee and we have provided our vision of such a file format to Prof. Hod Lipson of Cornell University who is leading the task group on AMF within this subcommittee.

“Our most important proposal was to keep a triangulated file, similar to STL, but to extend it so that it can contain much more information than just the triangles. We proposed to work with XML files, which are very flexible because any type of additional information could be added to the geometrical information. We also proposed more intelligent ways of describing the triangles so that the files would become smaller. Hod Lipson had some similar ideas and the XML format was accepted for AMF.

“Hopefully we can work on revisions of AMF in the future. It will also be necessary that not only Materialise, but other CAD vendors adopt it too. I think this will be more realistic if we start with something that is maybe not too far away from STL and not too complex.

“It is also important to note that, beyond STL and AMF, we still have our own proprietary file formats and methods to deal with file size and representing meta data in a very efficient way at Materialise, much more efficient than AMF. This is our core competence and therefore, something that we do not share openly, but ideally, AMF will become an intermediate standard format between our files and files of other parties, like CAD vendors or OEMs.”

Analysts

Dr Phil Reeves, managing director at UK-based consultancy Econolyst says,

“In terms of AMF, the concept is a real step forward over STL as it allows us to embed some intelligence into a part file, which will help in terms of data transfer and part validation. The real winner in the short term will probably be Objet as its Connex technology is the only one that will benefit from the multi material definitions, but anyone in production additive manufacturing will benefit from the improved data context. The mail limitation is the size of the uncompressed files and the time the curved facet definitions will take to slice. Of course it is also a bit of a chicken and egg, as it is not supported by either hardware or software vendors, but I am sure this will change.”

Users

There’s little awareness of the AMF format so far amongst users, but it’s clear that many are hesitant to commit to something at such an early stage.

For some time, sculptor Bathsheba Grossman has been working with 3D printing to enable the manufacture of her quite incredible works of geometric art.

Her comments are telling. “STL certainly is due for an update, and only an open standard will do. It’s nice that someone is thinking about it. Shooting from the hip after a glance at the Wikipedia page, this looks pretty bloaty too. It’s basically OK: the features are what you’d expect in an XML-based format and most of them seem up to par. Space savings are unimpressive compared to the mgx or OpenRP formats. The rounded triangles bother me: that’s an inelegant and unnecessary feature.”

To sum up she says, “Overall my reaction is guarded. But I’m never an early adopter of software that doesn’t come with new design capability, and this is that, so whether or not I like the format personally, my move is to wait and see whether there’s a bandwagon to jump on.”

London design consultancy, Within Lab, is a clear target user for the AMF format, developing highly complex structures that define what most consider ‘computer generated models’, particularly in the design and engineering space.

Dr. Siavash H Mahdavi at Within Lab says “At Within we have kept an eye on the AMF format for a while now. Its development has come from an interesting angle and can definitely aid in resolving some of today’s 3D printing problems. These problems, however, have been solved in many ways already through computer brute force.

“At Within, we design complex lattice structures on a daily basis and though file size can be a little annoying with file transfer, we use formats such as Materialise’s MGX format to compress the file. However, our lattice structures tend to be more complex than what AMF’s lattice definitions can handle requiring us to use the format in an inefficient way.

Many additive manufacturing machines deposit or fuse material in straight lines, such as the laser based systems. Curved triangles, though aesthetically pleasing and light in memory usage, move the responsibility of the retriangulation to the machine vendors. By maintaining a simple triangulated representation of your model, you maintain a better control over the final outcome.”

Conclusion

Looking at the responses across a broad spectrum of the industry involved with 3D printing, it’s clear that everyone is waiting for something to happen.

So we have a stalemate. CAD vendors won’t develop on AMF because its users aren’t asking for it. Machine vendors seem reluctant to adopt it any time soon. But the real challenge is for users, who might benefit from it and can’t do anything with it until there’s a) a way to output in that format and b) something to build it with.

In fact, I’ve only come across two instances where the AMF format is currently supported, one being the Materialise AMF support in its Magics software and the other Econolyst’s release of a webGL-based viewer to view STL and AMF files.

Other than these two instances, that’s it, folks. STL is a kludge – this we all know but at the moment and, for the vast majority, it works. It’ll probably continue to do so for the foreseeable future until a few parties on each side do something about it and build what has the potential to be a much more usable format.

Additive Manufacturing Format – a step forward in 3D printing

Default