As we get older, we inevitably start to lose our heroes.

It could be the death of a star like David Bowie or Lemmy from Motorhead, or your fondly remembered Design and Technology teacher at secondary school.

For me, the most recent example was the sad passing of Jens Nygaard Knudsen.

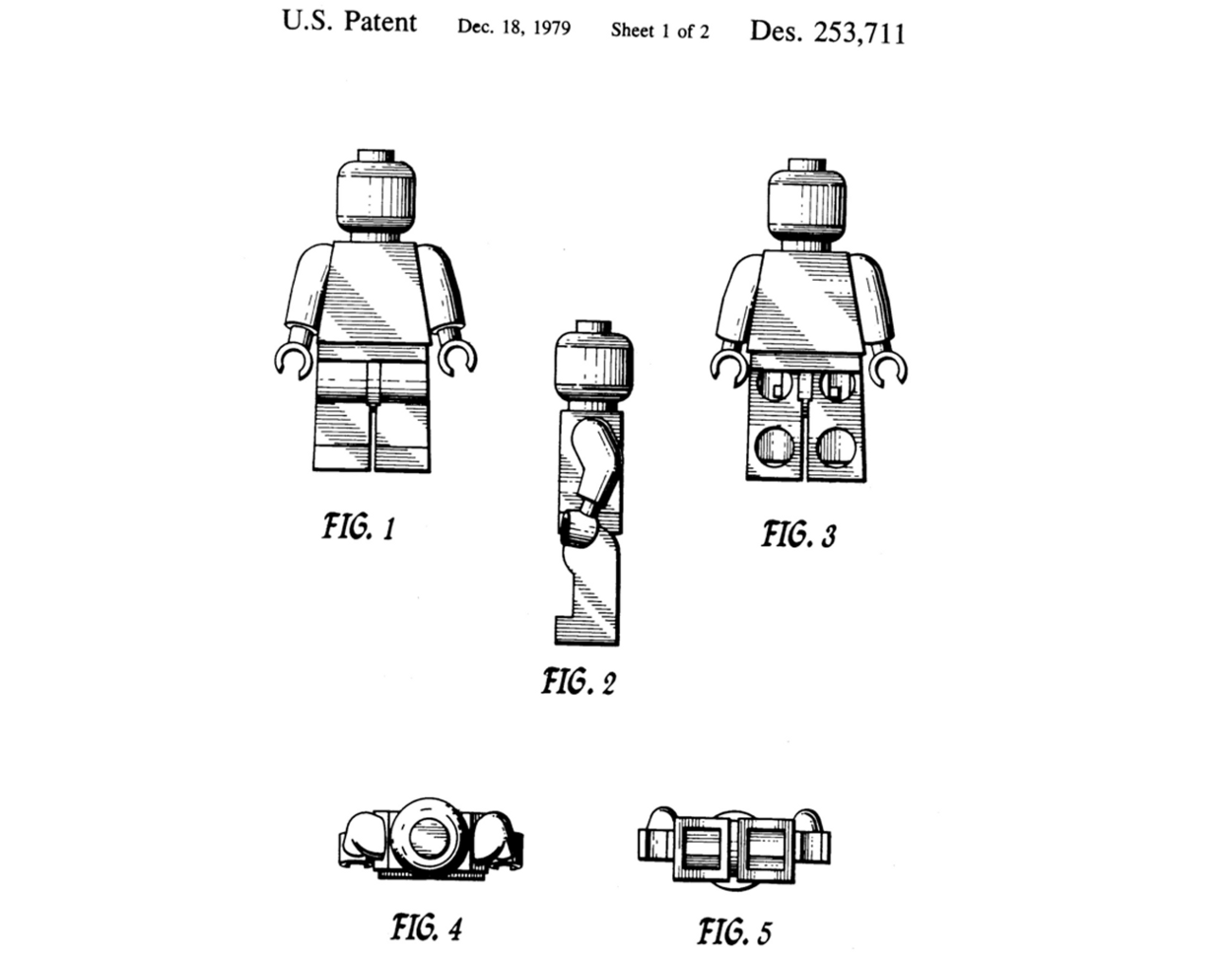

You might not be familiar with the name, but I bet you’re familiar with his most famous creation – the Lego Minifigure, or ‘Minifig’ for short.

I know that it was these little assemblies of 10 or so ABS parts (depending on their hair situation) that first kindled the fire of my interest in design, in engineering and in creating in general.

According to the official history of these wee people, it took more than 50 iterations to get the Lego Minifig right, prior to its 1978 launch.

If you want some more stats, just consider that, based on currently available parts, the Minifig comes in 864,993,504,100 combinations. That fillet around the head? It’s 2mm.

Reading the news of Knudsen’s death made me consider the impact that every product has, both on a personal level, in that connection between the user and the physical object, but also on the planet itself.

Years ago, I wrote about how I’d found a small box of Lego Technic discarded at the local recycling centre.

It struck me then, as it does now, that there is a lot of talk right now regarding the environmental problems associated with plastic.

Lego is proof that it’s not the material itself that is inherently evil. It’s how we treat it, how we misuse it, and perhaps most importantly, how we dispose of it.

Lego has been made from ABS for almost all of its life. Yes, the company has been exploring the use of a more environmentally friendly plastics, such as resins derived from sugar cane-based polyethylene.

There has also been talk of using a hemp-derived substitute. It’s all part of a corporate move away from the devil’s own material.

But surely once we start to consider the lifecycle of these products, there’s less need to reengineer decades of optimised production processes.

Lego is one of the most environmentally aware organisations around.

Its material experimentations are working towards a goal of all Lego bricks being made from sustainable materials by 2030.

Even by 2018, it was recycling 93% of the waste from its operations.

More importantly, Lego creates products that last.

If we’re going to use materials that can’t be readily broken down, can we at least ensure that those products have the longest life they can?

If your ABS Lego Minifigs are going to be enjoyed by multiple generations, they need to be made from a robust material.

I know that my kids have buckets full of these things, which still get played with today.

In that bucket are not just their own bricks, but also bricks that I had as a kid, along with bricks that belonged to my brother, 17 years older than me.

I dare say this bucket may get passed on to grandkids some day.

After all, we all know the appeal of getting down on the floor, tipping that bucket out and seeing where our minds and imaginations take us – even if the noise of that bucket emptying is almost as painful to parents as accidentally standing on a Lego brick in the middle of night.

Rest well, Jens. You’ve given generations of us fun, with many more to come.