With the rise of interest in topology optimisation, Al Dean ponders the current shift from designing explicit shapes to the creation of a design space that allows the power of computation to fill in the rest

Form follows function. This is what we’re taught during any design or engineering education. Define the requirements for the part or collection of parts you’re designing, then the actual shape follows. Whether that’s a simple bracket or connective component or something entirely more complex, such as a cylinder block, a roll cage for a desert racer or a space frame for a satellite, the same holds true.

We start with an idea of the material we want to use, an understanding of the requirements for that material, the performance criteria for the application and the requirements for manufacture or fabrication and work up a shape.

That shape is refined and iterated until is solves those three requirements. Today, we’re more likely to use digital tools to simulate that form against those requirements and probably undertake a good smattering of physical testing.

And all the way along this route, we’re adding in prior knowledge, expertise (both personal and from the team around us or partners/suppliers) and a fair old bit of guesswork.

That prior knowledge will always infl uence the decisions we make, right from the off. If we’re used to developing, say a bracket, we’ll probably guess we’re looking at some machined or water-jetted metal, welded at joins or cast into the near final shape with some post machining to clean things up.

This is how things have always been done and it’s within our genetic coding to use our brain’s power of prediction, based on prior experience, to inform decisions without really thinking about it.

But today we’re being told that the machines will be able to do much of this work for us. The rebirth of topology optimisation, driven by a groundswell of interest in additive manufacturing, is seeing all manner of solutions come to market that promise tools that will allow us to use the compute cycles of today’s hardware to remove much of this thought and planning. Read the marketing literature and you’ll see promise of loading a rough CAD shape, adding your boundary conditions and hitting “go”.

Come back 10 minutes later and you’ve got a solution to your engineering problem. The reality is that while these tools are, as claimed, incredibly powerful, their use isn’t quite so clear cut or straightforward.

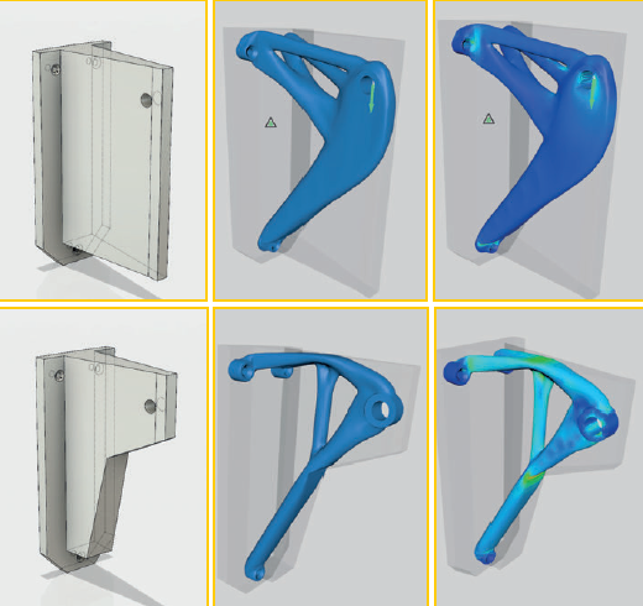

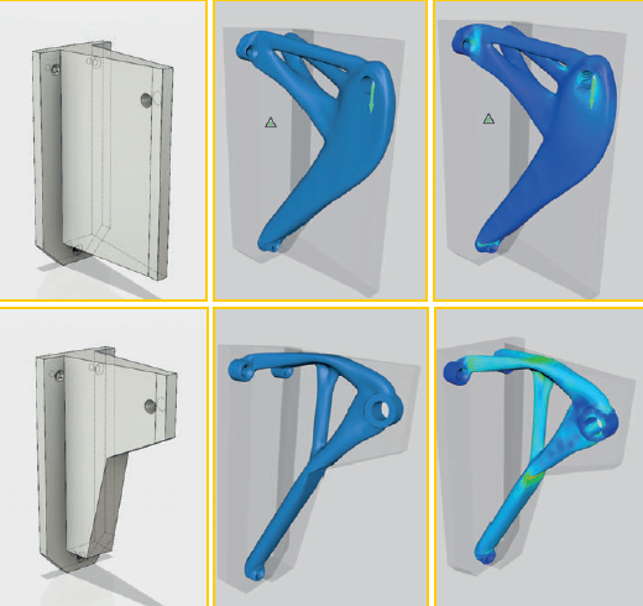

Consider the examples in the boxes above. Very simple brackets for hanging a mass away from a wall. The first row shows the basic shape that these things might occupy. But on running this through a topology optimisation system, you’ll see that the end result is going to interfere with the item it is interacting with.

The second row shows the same basic shape, but with a restriction beneath it to ensure that the item you’re hanging can swing unencumbered. The end result is very different in both form and function.

One is correct, one is not, but both conform to the requirements specified in the system. And this brings to mind my thought for this month’s article: engineering and design education focusses on the end result of the design process, both in terms of meeting performance requirements and, just as importantly, aesthetic quality.

With the rise of these types of tools, we’re going to need to supplement that learning to also include the concepts, theory and requirements of optimisation design space (commonly referred to as the domain) development within which computational algorithms can operate.

In short, we need to consider the space in which a component needs to operate, which might end up being empty, just as importantly as our innate knowledge predicts and informs our decisions of the shape of the fi nal form. If we get that design space wrong, too large or too restrictive, we’ll end up with an inappropriate solution.

Just as the old cliche goes “Crap in gets you Crap out”, what’s key here is that to make the most of these types of systems, we’re going to have to relearn some of our basics, retool in how we think about form and function and consider things from a different perspective to allow us to take advantage of design simulation properly.

Without that, we’re going to end up with poorly performing parts that cost more than the savings the systems promise.

What does this mean for the creation of a ‘design space’?

Default