The means of manufacture has always had bearing on design, writes Matt Batchelor. For all its benefits in prototyping, 3D printing can disconnect designers from the end process and its overall impact

For most of my career, there has been pressure to prototype digitally, driven by desire to cut time to market and R&D expenditure.

When I worked at Fiat, a new virtual reality (VR) cave, bought for a rumoured sixdigits in 2007/8, was still only as expensive as one of tens of prototype tractors built for mechanical testing. But in most cases physical prototypes crept back in, either to test hard-to-model jobs like harness and hose routing, or else to enable us to mock things up in cardboard, full-size, as real ‘rapid prototypes’.

In the broader industry, the twentieth century succession of design-isms gave way to the generic organic-ergonomic-smoothgoodgrips- sex-toy-potato school of styling, made possible by the wide adoption of CAD/CAM and the move towards making everything in lightweight, low-maintenance, no-finishing-ops injection-moulded plastic, typically in low-wage countries.

Somewhere along the way, it seems, many of us forgot the link between material, process and form that made many classic industrial designs elegant, appropriate and, crucially for a mass-produced product, efficient to make.

You couldn’t produce the Blueberry G3 iMac in anything other than injectionmoulded plastics, in the same way as if you started to make a car front wing with a sheet of aluminium and an English roller, it would come out looking like an E-type or Ferrari 250.

A handsome iron casting, drop forging, ceramic insulator or hardwood table leg can only ever look like what it is, by letting it be what the material and process will permit.

A refreshing change

Fast-forward to 2022, and it was refreshing to walk around the New Designers this year, looking at tables full of FDM prototypes.

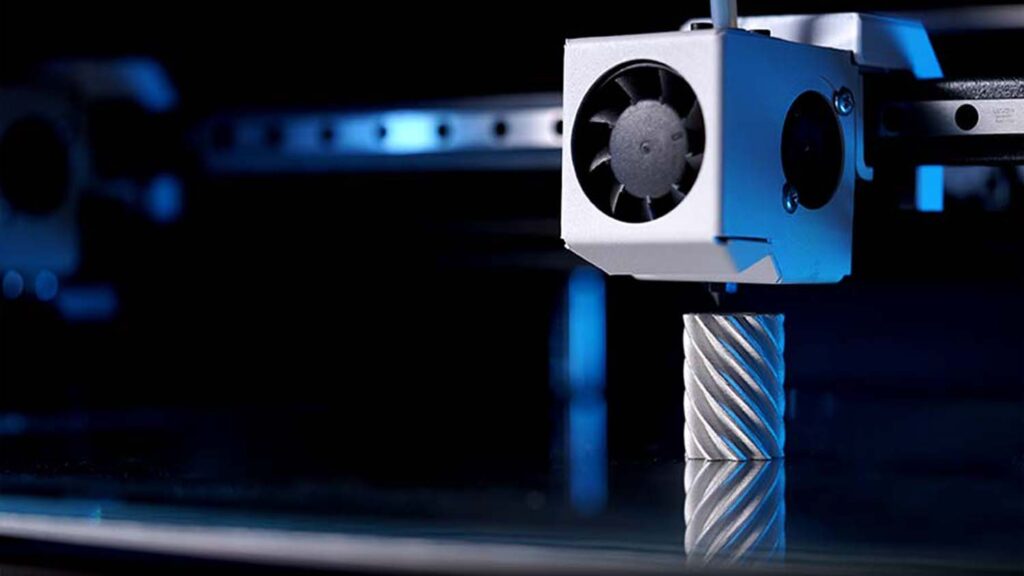

Low-cost, reliable FDM machines and maybe the end of ‘digital’ being a novelty means that cost and lack of workshop machinery are no longer a barrier to a designer making quite a sophisticated ‘looks-like’ or ‘works-like’ model. The trouble is that these are rarely ‘made-like’ models; but why is that a problem?

On a minor level, things like less-controlled tolerancing, shrinkage, warpage and non-precision surface finishes compared to moulded or machined parts mean that even with state-of-the-art bureau machines, we’ve often had to debug the AM prototyping process before we debug the design.

The real problem is that design is not just the shape of an object, or even just its physical properties. In the design and engineering professions, we know about anthropogenic climate change, the many impacts of resource extraction, processing and disposal, and the impossibility of infinite consumption on a demonstrably finite lump of rock.

As a result, there is a consensus that we should be responsible for at least minimising or even eliminating the impact of the things around us.

I’ve heard it said that 95% of the cost of an object is determined in the first 5% of the design process. I would argue that the same is true of the broader resource cost of that object in its existence, use and eventual disposal.

If we are to meet the ultimate design requirement of making sure that humans can continue to live without causing our own extinction, we need to be careful about the tools we use and when we use them

Information loss

In the prototyping phase, 3D printers need an explicitly defined 3D shape to print, which means we lose some information about the material and the energy needed to turn it into an object.

Standing in an iron foundry, the enormous amount of thermal energy going into melting the iron is obvious. But then the complexity of shape that sand casting provides allows objects to be made more efficiently of one or several castings — rather than, say, a complex welded assembly or machining job.

Extrusions are an amazingly efficient way to get a complex functional cross-section, provided that complexity can be in two dimensions.

Many early cultures independently learned how wood can be split, steam-bent and shaped to make high-performance sailing ships. A Viking ship on a close reach looks a thousand years more advanced in its speed and efficiency than a Maersk E-Class forcing its way through the water.

At Instrument, we’re working on a sustainability concept that involves some very involved metal forming to replace plastics.

And while our SLA printer has let us iterate a forming process very quickly by printing tool inserts, we could not make any progress if we weren’t working on a material of the right grade and gauge to make sure it all works in practice. By prototyping the process as well as the part, you naturally tend to design for the minimum of wasted material, energy or complexity; which details work and which can be forgotten.

It may be financially convenient to have a little shape-it-all box in the corner, but if we are to meet the ultimate design requirement of not making ourselves extinct, we need to think carefully about which design tools we use and when.

3D printing is amazing, but I sometimes worry that it belongs to the bad old ways.

About the author:

Matt Batchelor is an industrial and engineering designer, and co-owner of Instrument Industries, a London-based design and manufacturing firm.

He tolerates the company’s SLA machine, but wishes it was a Bridgeport. www.instrument.industries