With a new, larger workshop space, Al Dean has been itching to put together his next big bit of making kit. So how has the first fortnight on the X-Carve CNC router been? It’s been fun, with a wee dose of aggro

There’s nothing like three boxes stuck in Customs to send your blood pressure rising. And if you’ve bookmarked the Post Office’s tracking page on your mobile phone, you’re running the additional risk of a wearing a hole in the gorilla glass, with all the constant refreshing you’ll do.

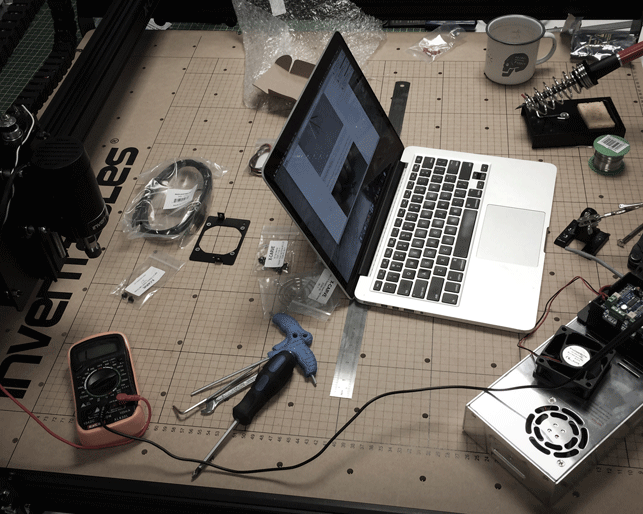

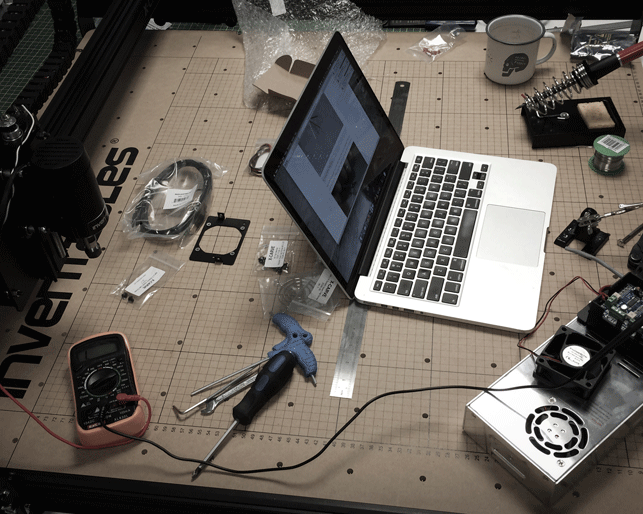

The X-Carve is a beast (particularly the 1,000 x 1,000mm version.) You’ll need to brush up on your soldering and wiring chops. And you’ll need coffee – a lot of coffee

This was me, three weeks ago. I’d put in my order for Inventables’ X-Carve CNC router back in April and I felt like I’d been waiting ever since.

Once you receive the shipping notification, you get to watch your packages, somewhat voyeuristically, make their way from Chicago, across the Atlantic, to a nameless logistics park somewhere near Heathrow, where they’ll sit until they receive customs clearance. Then it’s a trip up to the sorting office to pick them up. Only then can the real fun begin.

For those of us in the design and engineering trade, model kits bring back fond memories – some from childhood, some more recent. Having a 1,000mm x 1,000mm CNC router delivered provides the same sense of anticipation, but on a much bigger scale.

Build up

When it comes to the build up, Inventables has done a pretty good job of making the process clear and efficient. Everything is colour coded, labelled and counted, matching the online instructions and associated video.

The first half of the build up was spent on the mechanical aspects. This took about three days, spread over the course of a week, and didn’t present too many issues.

While much of the process is pretty self-explanatory, I’d still suggest an initial browse through all of the instructions; a second, more thorough read-through; then an in-depth review as you carry out each stage of the build.

There was only one snag: a pack of missing socket cap screws. Inventables shipped some more from the US but, to be honest, it was quicker to drive over to my local industrial suppliers (MSC Industrial in Wednesbury) and pick up a box of 200. M5s always come in handy, right?

Then it was on to the part I was dreading – the wiring and electronics. I’ve never been all that good at soldering, stripping cables and working out wiring routing. I’m the guy who always has to google how to wire a three-pin domestic plug.

That said, over the course of the next few days, I learned a lot, discovered how to do things I’d never done before and developed a deeper appreciation of what goes into a numerically controlled machine, as well as some of the theory and practice behind it.

Then, in the final stages, I hit another snag. The X-Carve is controlled by an Arduino with a special-purpose machine control ‘shield’ that plugs into it – but a single, knackered terminal block once again delayed completion of the router. Again, a replacement needed to be shipped (and, to be fair, Inventables has been good as gold with this area of support).

But I’m happy to say my X-Carve CNC router is now up and running. The machine is tuned and some test projects have been completed. Now it’s time to get on with some real work.

Next steps

So what’s next? The first thing I want to do is dump the Inventables Easel software and use Autodesk’s Fusion 360 CAM tools instead. These give you more control over the process, as well as how and where your cutter is working. I’ve cut a few test parts and the workflow seems to function OK.

If you’re tempted to try this yourself, and haven’t had much experience with this type of machine, you’ll need to use a different controller application (Universal G-Code Sender is good and free) and output your G-code from Fusion using the GRBL post processor.

I’m also going to hook myself up with a touch probe for finding the top of workpieces more accurately than simply eyeballing them. There’s a nice little hack for this that is well-documented online.

I’ve also got a tidy little plan for a low-profile work holding vice in development, too.

But first, I’m going to disappear into the wilds of a Suffolk farmer’s field with my ancient caravan and get me some holiday fun. Have a good summer folks!

What’s Inventables new desktop CNC router kit like to use?

Default