Whilst admiring the simple yet beautiful design of her new iPhone 6, Tanya Weaver considers its materials and wonders, with the continuous advancements in materials research, what the future may hold

The beauty of mobile phone upgrades is that, following the completion of your contract, you’re entitled to a brand spanking new phone. Luckily for me, my 24 month contract ended recently and I’ve bagged myself the new iPhone 6. In white, if you must know.

I have been a very happy iPhone user since Apple first entered the smart phone market in 2007. Now, I can almost see some of you rolling your eyes with ‘it’s just a phone’ and ‘not another Apple geek’.

And yes, other mobile companies have caught up and Apple may no longer be the leader of the smartphone pack but I would argue that it certainly produces the most beautiful of the mass produced smart phones.

Yes, the iPhone 6 is bigger and thinner but what impresses me is how all its innards are packaged in a smooth and sleek, continuous form. It’s not just an exercise in packaging the technology in the most robust and functional materials.

It’s been so meticulously designed and considered from the way the glass cover curves down to meet the anodised aluminium enclosure to the placing of the buttons and the audible click as you slide the mute button.

It just indicates to me that Jony Ive is not only an industrial designer extraordinaire but certainly knows a thing or two about materials and the manufacturing processes that are capable of constructing his vision. (Yes, I know it’s not only Ive sat at Apple Towers working away; his engineering team will have to take some credit).

//www.youtube.com/embed/ef69BUlge-A

However, following the launch of the iPhone 6 there was something missing from the design that the press had pretty much convinced us would be incorporated – a sapphire crystal display.

Gorilla Glass has been the display material of choice since 2007 but the press speculated this was all about to change when in 2013 Apple entered a $578 million partnership with GT Advanced Technologies, a technology company producing advanced materials and crystal growth equipment. This vast sum was allegedly to set up a sapphire crystal production plant at Apple’s production facility in Arizona.

By February 2014, with the iPhone launch just seven months away, the press shifted into overdrive reporting that Apple would be using the facility to produce a new sub-component (i.e. the display) for future Apple devices. New, by the way, because the home button and camera lens are already made of sapphire.

But this was not the case. Why? Well, although sapphire has many virtues such as being super hard, thin and scratch resistant it seems that its downfall is that it’s believed to have a tendency to shatter if dropped from relatively low heights.

But despite a no-show on the iPhone 6, the press still believe Apple has something big up its sleeve for sapphire as it applied for a patent a few months back for technology that hardens sapphire glass.

So, as well as the display of the Apple iWatch, which Apple has confirmed will have a sapphire display, there may be other products featuring sapphire that will make its way out of Apple Towers in the coming years.

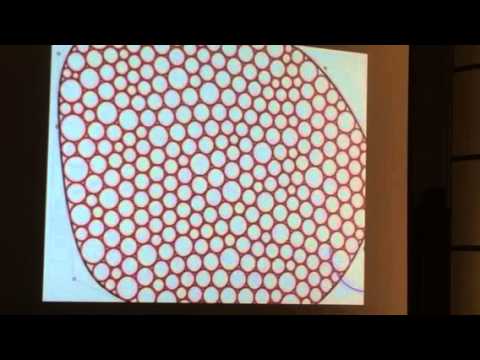

Meanwhile, Apple’s arch rival Samsung, who it has met in court a few times wrangling over IP issues, has been making some partnerships of its own, namely in Graphene research. Graphene is described as a one-atom transparent layer of pure carbon that can conduct both heat and electricity. Discovered at the University of Manchester in 2004 and winning the Nobel Prize for Physics in 2010, scientists are in a race to synthesise this ‘miracle material’.

The Samsung Advanced Institute of Technology has partnered with Sungkyunkwan University in Seoul, South Korea, to develop a breakthrough synthesis method of producing Graphene.

The hope is that this will pave the way for the commercialisation of the material for use in consumer electronic devices. So, proper flexible displays may not be a pipe dream for long.

Elsewhere, many companies are pioneering the use of advanced materials. Engineers at BAE’s Advanced Technology Centre are investigating a smart skin concept that will be able to ‘feel’ through thousands of micro-sensors in the surface of the material.

Whilst IBM Research are working on various aspects of phase-change material (PCM) technology with the view to one day replacing NAND flash memory in solid state drives (SSDs).

But of course we can’t talk about advancement in materials without mentioning 3D printing; materials have come on leaps and bounds since the days when it was called rapid prototyping.

Remember those yellowing and brittle prototypes? Well, the raw materials have certainly progressed and today you’ll find anything from flame retardant nylon through to titanium, chocolate, bone-like material, full colour sandstone and even glass. Well, the latter is still in development by HP, which plans to enter this arena by bringing the 3D printing of glass to market.

Then, those at his year’s TCT Show may have spotted a 3D printer on MarkForg3D’s stand that can print in another new material — carbon fibre. Founder Greg Mark, MIT graduate and aerospace engineer, knows a thing or two about advanced materials having designed and manufactured high-performance composite race car wings for years.

In a bid to reduce carbon fibre material costs and a means of automating the composite layup process, he came up with the Mark One 3D printer. But, if you wish to get your paws on what is being billed as the world’s first desktop printer capable of printing composite materials, you’ll need to find a spare $5,000.

All of these advances in materials, and I know there are many others besides, does make me feel excited about what the future may hold. But for the meantime I’ll keep admiring my new phone.

What will materials research lead to?

Default