Delcam covers many aspects of the product development process within its software portfolio, but its core focus continues to be on CAM. The company’s flagship product, PowerMill, has long been one of the most advanced systems for machining highly complex 3-axis mould and die type components, but in recent years the system has evolved and now handles five-axis machining as well as more routine production machining tasks such as hole drilling, and basic pocketing. While Delcam continues to expand its areas of coverage, for the 2010 release the development team has concentrated on something that affects every single one of its users – that of making the system faster.

There are two key technologies in PowerMill 2010 that address this, both of which are made possible with modern multi core workstations with plenty of memory.

First off, PowerMill has gone 64-bit, which when combined with a 64-bit operating system, means users can work with much bigger datasets and even more intricate CAM operations. Previously, users would hit a limit at 3GB and when creating complex toolpaths with a fine surface finish, often had to split a job into separate chunks.

Alongside its 64-bit capability, the 2010 release also sees changes in how the system works with multi-core and background processing. While these are two separate disciplines, the two are related, so I’m going to try and tie them together. First off, let’s look at multi-core or multi-threading.

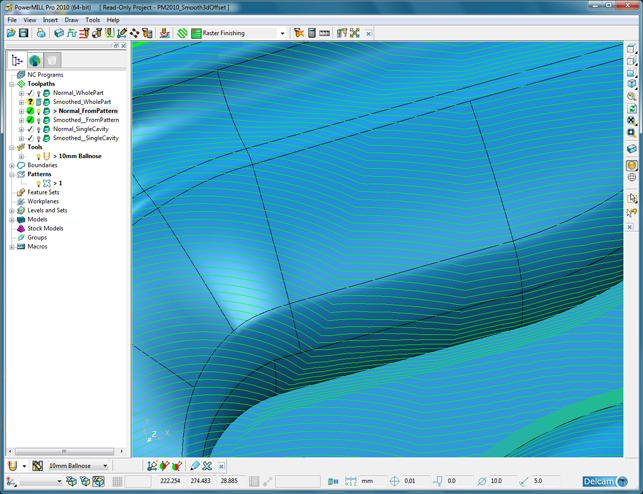

The new 3D Offset smoothing options remove the potential for optical marking by smoothing out sharp changes in cutter direction

The splitting of calculations across multiple processing cores can be done in one of two ways. The basic approach is that a sequence of calculations can be divided and sent to different cores. In the world of CAM that would mean having a string of operations that are sequentially sent to each core for calculation – while this is excellent for speeding up batch processes, there is a more intelligent alternative.

What Delcam has done is looked at which specific components of an individual tool-path are most suitable for multi-threading and split those portions of the calculation across multi-cores. A prime example is anything based on raster machining – the nature of the calculation can be very multi-threaded (with each pass calculation sent to a separate core). As a result, even a single operation can be multi-threaded and calculated in a much more timely manner. Alongside this, background processing tools have been introduced to PowerMill. This means that almost everything can be ‘sent to a queue’ and processed, while holding back sufficient system resources for users to keep working on the current PowerMill session without it locking up.

While individually these enhancements look impressive, when you consider them together, you can see how they work in concert to speed up PowerMill dramatically. Delcam has been doing some testing and conservative estimates show that, when compared to the last major release, PowerMill 2010 is about 2.5 times quicker in calculation. This is obviously dependent on the type of operation and workstation specification, but it’s a good guide as to what to expect. Also, it’s important to re-iterate that users can continue to work while it’s calculating, so the system will be much more productive.

New strategies & operations

Alongside the updates to the core PowerMill architecture, there has been work done across all areas of the system in terms of functionality. This has resulted in 18 major new features and these are the highlights.

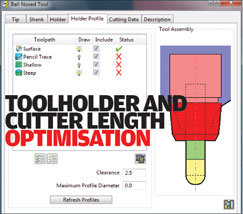

The first relates to using digital tools to find the most appropriate toolholder and cutter configuration for a specific job. While for simple parts this might not be appropriate, for complex machining tasks it could arguably be considered as essential.

The new Toolholder profile analyses the programmed part to find the most appropriate toolholder and cutter length that can fit into it. It does this with a subtractive analysis that calculates the largest volume that can fit into a part’s machining process – essentially a space envelope into which the toolholder can be optimised to avoid collisions as well as the length of cutter in that holder (shorter is better). Other systems offer similar tools but on a per-operation basis, rather than looking at the complete set of operations.

Click here for an exclusive Develop3D PowerMill 2010 Workflow

While on the subject of collision avoidance, this 2010 release also sees work done to improve the 5-axis related collision avoidance tools. PowerMill has had these tools for some time, but they’ve been improved with this release to make the movement of the head and cutter around the ‘thing to be avoided’ much more fluid. It does this by looking ahead along the tool-path, finding areas where an alignment change is needed, then adding smooth lead in/out of those movements. This results in smooth head movement and better surface quality.

Moving onto roughing, there have been a couple of areas of work. Firstly, the system now actively avoids thin slithers of material left as a part of previous operations. While this might sound a small thing, when there is a high-speed machine ripping out large quantities of metal and it impacts a thin slither of metal, there’s huge potential to damage both the part and the cutter – this is particularly true when working with insert-based cutters. For ‘lights out machining’, it can assist greatly with reducing risk.

Almost at the opposite end of the spectrum, there’s been work done to optimise the ordering of fresh air cutting during roughing operations. This means safe moves and movements between tool-paths are completed much more efficiently.

Finally for roughing there’s a new option when roughing into tight corners. Typically these types of operations, where much of a shank is cutting material, cause problems with cutter chatter, but the new feature uses a progressive approach to remove material incrementally.

The final major update for this release is the new smooth 3D offset operation. This uses a unique smoothing algorithm that’s applied across whole tool-path rather than just corners. In 3D offset operations, it’s often that sharp changes in tool travel occur as the offset is progressed across the form of complex parts – this causes stress on the cutter (as the machine makes the vector change) and can also cause witness or dwell marks. This new operation adds smooth links where those change occur to smooth out the motion of the cutter and to maintain feed/speed rate – improving cutter length, reducing machine wear and perhaps most importantly, improving surface quality.

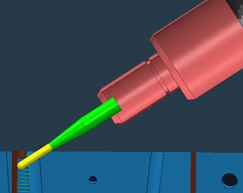

When working in deep pockets and around complex features, the new toolpath smoothing option reduces tool movement and cutter wear

As a 3D offset is propagated from a single entity (such as a line) across a complex part then errors and problem areas increase as further boundaries are reached. The new Delcam algorithm smoothes out those issues within control to a set tolerance – this isn’t simply arc fitting where there are inflection points in the tool-path curves, but something more complex that both smoothes out the tool-path and maintains contact with the surface of the part (which doesn’t always happen with arc fitting and complex geometry). The result is a better surface quality and as a result less hand finishing/further operations to clean up those problem areas.

Conclusion

This is the second major release of PowerMill in less than six months. It builds on Delcam’s efforts to rationalise the user interface (dialogs are much less complex with greater graphic feedback). It also sees work done to extend the system’s reach into both more complex forms of machining and the more routine tasks. But what PowerMill 2010 is really about is making the whole process more efficient – firstly in terms of machine tool-path quality and hence end part quality, but also in terms of enabling a much more efficient part programming workflow.

The tools introduced in PowerMill 2010 allow users to create toolpaths, optimise them and iterate the process in a much more fluid manner. PowerMill has always allowed toolpaths to be edited on the fly, but this release enables much more concurrent calculation, allowing users to continue to work as operations are calculating. That’s always going to result in a more efficient workflow, rather than waiting for what could potentially be hours, only to find that tweaks are needed to achieve the best possible part in the best possible time.

Machining and CAM is something that’s rather delightfully easy to quantify compared to many of the other technologies we look at. What counts is part quality, both in terms of the requirements of the application and the customer, and that the machine tool is running, on quality toolpaths, as much as possible. PowerMill excels in these areas like never before.

What’s also worth noting is that now Delcam has done the groundwork, these same capabilities will be implemented in the company’s other machining products. We’ll be looking at those as they hit the market, so stay tuned.

| Product | PowerMill 2010 |

|---|---|

| Company name | Delcam |

| Price | on application |