CloudNC’s CAM Assist solution is now available for Mastercam users, both as an AI add-on for the Mastercam platform and through North American manufacturing software resellers.

This means it is available to a larger audience than previously across North America and elsewhere.

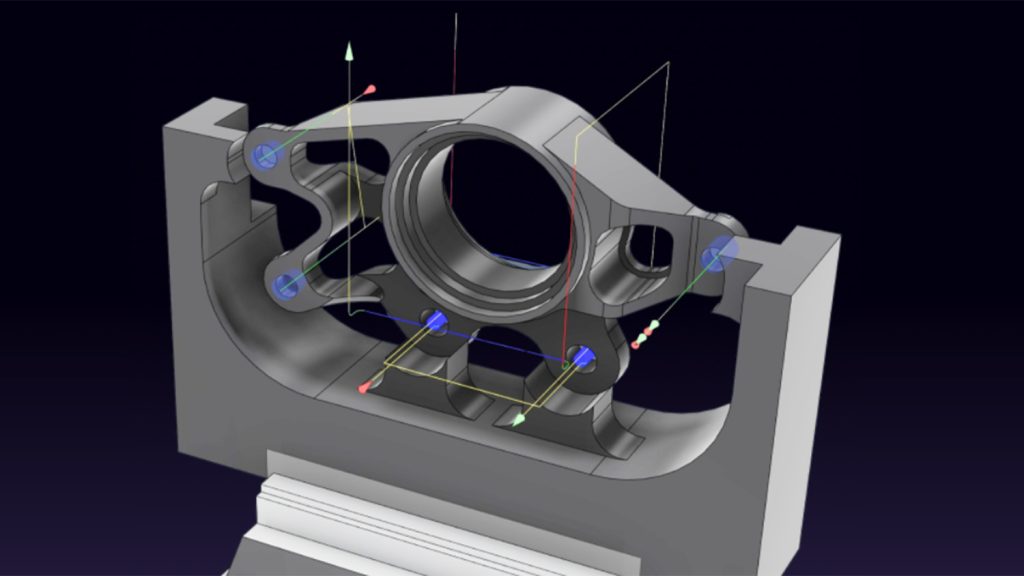

The solution uses AI and computer science techniques to generate ‘intuitive machining strategies’ in seconds or minutes – depending on complexity – for 3 and 3+2 axis CNC machines. These strategies typically take CNC machine programmers hours or days to create manually.

A reduction in the time it takes to program a CNC machine to make a component, a bottleneck in many factories, means that more parts can be manufactured in the saved time.

CloudNC CEO Theo Saville, said: “Mastercam has deep market penetration with expert machinists and workshops that serve specialist sectors, like aerospace and automotive, and our research suggests over 10% of CAM programmers worldwide have access to Mastercam.

“Now that CAM Assist is available to them, those users will benefit from CAM Assist’s ability to save the average machine shop over 1000 hours a year – changing the game for a large slice of the global machining sector.”

CloudNC says that its AI generated cutting parameters and tolerance verification cycles reduce waste by ensuring ‘right first time’ components. CloudNC’s new CAM Assist feature, Cutting Parameters AI, automatically generates physics-based feeds and speeds for any CNC machining scenario in seconds, resulting in an increase in productivity by an estimated minimum of 20%.

A calculator on CloudNC’s website shows manufacturers how much money they could save if they started using CAM Assist instead of manual part estimation. Resellers of CAM Assist include Shopware, CAD/CAM Consulting Services and In-House Solutions.