In the journey towards more sustainable maritime transportation, Hyundai Heavy Industries has reviewed how it collaborates and manages data in order to lead the way on developing more eco-friendly marine engines

International shipping has set itself on course to a zero-carbon emissions future. Targets drawn up by the International Maritime Organisation (IMO), the United Nations agency responsible for regulating shipping, aim to reduce the industry’s greenhouse gas emissions by at least 50% by 2050, compared to 2008 levels.

The IMO has called for the industry to embrace new technologies, new fuels and innovation, adding that exciting research and development into low- and zerocarbon marine fuels is already underway.

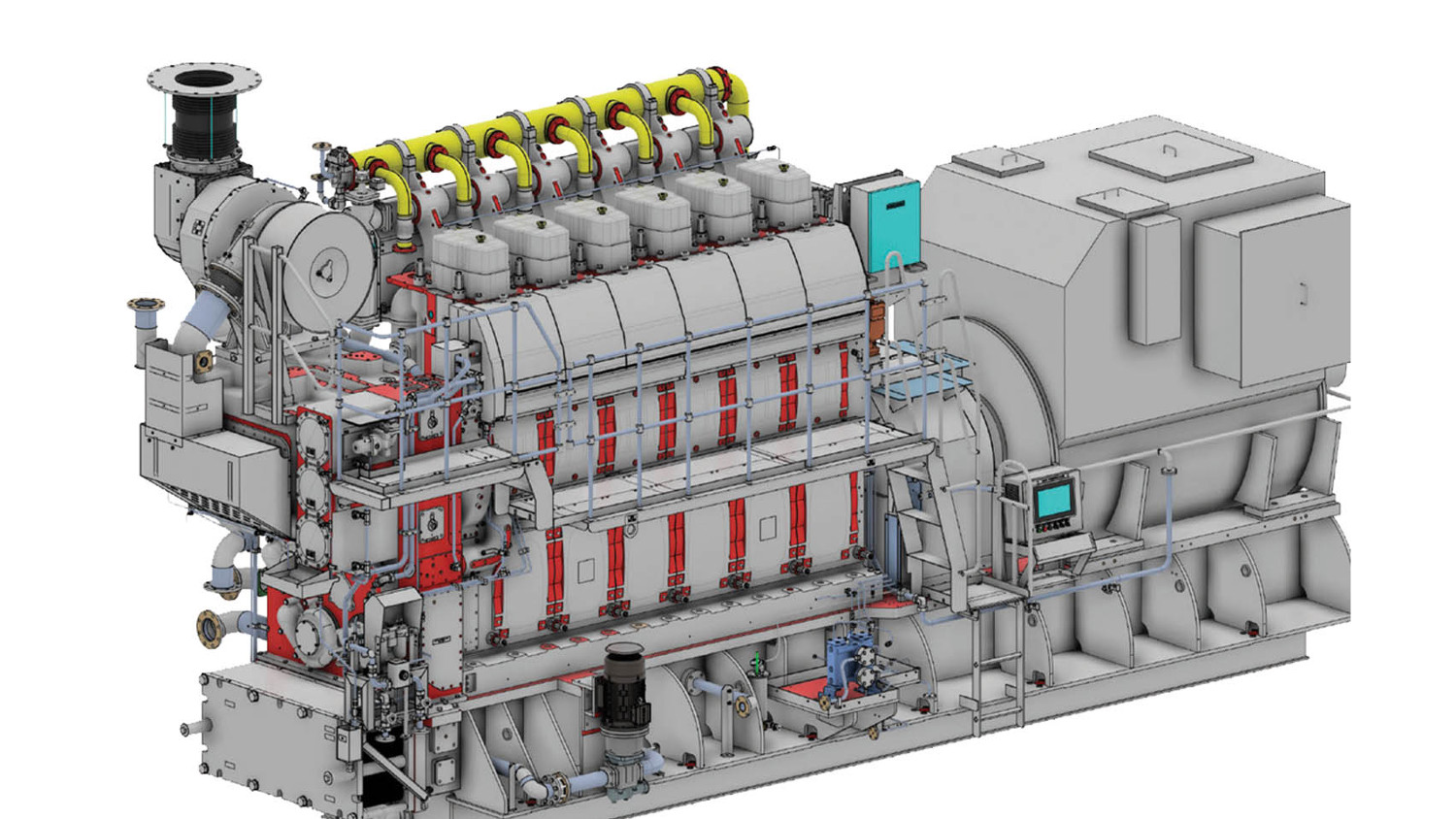

One company leading the efforts is Hyundai Heavy Industries’ Engine and Machinery Division (HHI-EMD). Based in South Korea, it is one of the world’s largest marine engine manufacturers, with a 35% share of the global marine engine market.

As well as making its own brand of mid-size engines under the HiMSEN brand, the company is also a leading manufacturer and supplier of eco-friendly marine facilities and onshore energy plants. These include eco-friendly gas supply system Hi-GAS, NoNOx selective catalytic reduction system, and ballast water treatment systems.

An Kwang-hean, president and chief operating officer of HHI-EMD, says that the company’s plans to become the world’s number one sustainable energy provider for ship propulsion has seen it invest in its technology development.

HiMSEN has recently shifted its attention to dual-fuel engines capable of running on both liquid and alternative eco-friendly fuels, such as liquefied natural gas, to become more efficient and reduce pollutants.

“We’re seeing significant interest in alternative dual-fuel energy,” says An Kwang-hean. “Using dual-fuel engines can reduce carbon dioxide, sulphur oxide and nitrogen oxide emissions noticeably compared to using diesel. As requirements for industrial decarbonisation increase, dual-fuel engines are expected to make a significant contribution to the sustainable shipbuilding industry.”

He adds that as the HiMSEN engine business grew, it uncovered a need for better engineering collaboration with its licensees, and data management.

In shipshape fashion

The first step was to transition its 3D models for HiMSEN engines to Dassault Systèmes Catia and utilise the 3DXperience Platform.

“Our main users of the platform are design engineers, focused particularly on mass production development of the HiMSEN engines,” says HHI-EMD senior manager Kim Seungmin. “They use Catia for 3D modelling, as well as Enovia and Delmia for managing specifications, engineering BOM and manufacturing BOM. It was important for us to be able to handle everything within a single platform.”

Now, engineers use Catia to design every facet of the HiMSEN engine and build a standard library of parts in Enovia.

“The entire engine model is created using the dedicated capabilities in Catia for mechanical engineering,” says Seungmin.“And with the specific functionalities offered, we can easily model pipes. For 3D modelling, we also made a template that suits each business unit to build a standard library of parts to help with decisions around dimensions and shapes.”

Taking advantage of the standardised workflows on the 3DExperience platform, HHI-EMD has been able to connect the dots across its product development processes, from design and engineering to manufacturing to enterprise resource planning (ERP). As it grows its engineering competence and pursues new joint ventures, HHI-EMD executives see the platform as enabling the company to collaborate with new licensees and ship owners, from wherever they are in the world.

“We can work in multiple windows simultaneously with different parts in real time within the platform,” Seungmin says. “Our partners and customers can view 2D and 3D models on the web without having to open the CAD file. Also, when we share 3D models of large assemblies, they load much faster and this makes the process more convenient.”

In parallel with the platform implementation, HHIEMD consulted Dassault Systèmes to develop a longerterm digital transformation strategy for its evolving business.

Hyundai Heavy Industries – all hands on deck

Seungmin explains that the team consists of around 120 internal and external design engineers all using the 3DExperience platform.

“Soon, we plan to introduce advanced planning and scheduling on the platform to strengthen our product development competitiveness and, ultimately, we plan to expand our use of the 3DXperience platform to make our production site even smarter,” he says.

One key area to benefit from this is the way in which engineers now generate the bill of materials.

“Before, we manually exchanged data between our CAD, PDM and in-house BOM systems,” Seungmin says. “All 3D models, 2D drawings and part list data from the CAD and other systems were sent to the BOM system after an internal approval.”

Then, after going through modification and manual inputs, the final BOM data was sent to the in-house ERP system, he continues.

“Now, we use Delmia to generate the production BOM from the approved design engineering BOM to reduce errors. We can also make changes to a design and all associated drawings, models and BOM data automatically update too.”

As it sees the benefits of this approach, HHI-EMD is now looking at ways it can further achieve a seamless data flow across the entire product development lifecycle.

“We plan to extend the scope of BOM in our manufacturing process,” Seungmin says. “This will enable us to connect the specification and engineering BOM to the manufacturing BOM and achieve a consistent and trackable BOM management system.”

Working within a single unified environment, HHIEMD finds its engineers are able to focus on developing new technological innovations and solving new engine design challenges as they no longer have to spend time switching between different applications and converting data, keeping the development workflow as economical as its new engines.