Since 2006, Carl Bass has headed up Autodesk, developer of the ubiquitous AutoCAD application, as well as Inventor, 3ds Max and many, many others. Before Bass took over, Autodesk was seen as predominantly a one product company and had gone through a drawn out reorganisation into vertical market groups under the then CEO, Carol Bartz.

While Bartz addressed the structure of the company, Bass is very much a technologist and under his tenure Autodesk has expanded rapidly, not only acquiring companies such as Alias but also developing many new code streams for potential products.

These ‘projects’ can be seen on the Autodesk Labs website (labs.autodesk.com) and at Autodesk University (AU) in December 2010 even more applications were added.

Our conversation began with the subject of the Fusion direct modelling technology that started off as an Autodesk Labs project.

The product is now included in the Inventor box, and will soon be shipped with every AutoCAD.

We asked: why pair up a standalone modelling tool with AutoCAD? Bass explained, “I think Fusion is a more approachable technology for 3D modelling than a parametric feature-based solid modeller like Inventor.

It’s a little bit more familiar to people who may have started with AutoCAD, Rhino or used any of the NURBS modellers. “Moving from there, to something that has a little bit more precision, a little bit more flexibility, like Fusion, is probably a good step towards using parametric solid modellers. It also depends on whether you’re doing things like conceptual design.

Here Fusion may be a perfect fit, you may never need more functionality than that. So we think that Fusion, by itself, is actually a good way for AutoCAD users to do more 3D. “And then door number two is that, as we’ve seen other businesses demonstrate, having a non-history based approach to modelling is also a good idea and a companion to traditional history-based feature modelling.

But one of the things that Fusion does well is its integration with Inventor, in that you can move back and forwards between the two – which I guess is different to some of the other vendors who have decided to implement this…by branding! You know, calling something the same name doesn’t make it do that.

“Fusion is the idea that you can do history-based parametric modelling and non-history based. So you could imagine it living inside Inventor as an environment, like sheet metal or cabling. So it makes sense as a companion to Inventor and it makes sense as a companion to AutoCAD.

I don’t think there’s anything wrong with it existing in both those ways. So it has a life attached to AutoCAD and has a life attached to Inventor. And whether it’s actually the identical executable inside or not. I don’t think it matters all that much.”

For now Autodesk is giving away Fusion as both a Labs project and on the install disks of its core products. We asked if Autodesk had any plans to charge customers an incremental fee for Fusion? Or delve deeper into providing small downloadable apps for new platforms like the iPad.

Bass quipped: “There are worse things than that! It’s not like the AutoCAD and Inventor business sucks. We generally do better as a company when we sell less products. And if you look at the history, whether it’s the acquisitions of technology or the technology we develop, we tend to try to put it into existing products.

Autodesk has been experimenting with different ways of selling its applications. There are the new product suites, as well as small applications available through the Apple online store. We asked Bass how these new product formats came about.

“Our default position is: ‘Let’s take this and find the appropriate place to put it in, where it’s already integrated.’ We had a debate on small apps versus big apps and I think you know that I’m a fan too of the small app.

“One of the interesting things here is that with almost all of the small apps none of the data moves from one to the other. If you play ‘Angry Birds’ you don’t worry if the data doesn’t move. So with most of the apps there is almost no interaction.

So, for example, I do Sudoku and interestingly enough it does allow you to mail a puzzle to someone else, and you try your hand at it but the workflow around it is almost non-existent. “So apps are very limited and just exchange a PNG or a JPG.

The question is when do you want these bigger applications, and when do you want the smaller ones? The smaller ones do particular tasks, and are well suited to it. On the other hand I’d rather take Fusion and put it in AutoCAD and put it in Inventor. We’ve tried very hard to put as much capability as we can in single products.

So Inventor gets richer and richer. And you buy Inventor Pro and you get sheet metal; you get cable and wire harness, you get pipe and tube, analysis. I mean the list just goes on. “If you look at others [other CAD vendors] who sell in a different way, it’s a different business. If you want an IGES translator, that will cost another $1,200 a year.

The IGES translator costs more than our product costs! We provide modelling environments, complete with file exchange, in and out, for $1,000 [Inventor LT], and other vendors have modules. It’s a different business.

I think Dassault Systèmes and Siemens are the worst at charging people for a drop down menu, whereas PTC has a lot of modules but not nearly the degree of modules. Ours on the other hand, we’re trying to put more together in a single product and then we put more products in a suite. We think it’s great for customers.

“There are two advantages with the suites. One is clearly that there’s a price advantage. The other is, we did a lot of work on the interoperability and there’s a bunch more stuff coming in the Spring that makes the workflows from the products in the suites, better together.”

PLM

To give it its proper name, Product Lifecycle Management is an area where the Autodesk CEO has gone on record as being a non-believer.

Paraphrasing Bass he has gone so far as to say that the only people with a PLM problem to solve are the vendors trying to sell the PLM products to their customers. However, there were rumours that

Autodesk was looking to get into data management deeper than it currently is with Vault. So what of the rumours?

I think the CAM market is one of the next ones that needs an overhaul, in terms of capability. Most of the software there is just too difficult for most of the people

“I would suspect right now, we’re getting close to as many people using Vault as any other PLM system in the world,” retorted Bass. “The standard Vault, we don’t charge for it, it’s included but there are tens and tens of thousands, of implementations involved.

There’s a push for more efficiency driven by the economy but I also think some of these products have now got to the point where keeping track of that data becomes difficult. I think we did well on Vault.

I’m not trying to create PLM, which we can have a conversation about in a second, I think really it’s PDM [Product Data Management], or some kind of data document management. “I’ve said many times that nobody became an engineer to use a data management system and most engineers’ natural reaction is one of reluctance.

“I think there are two things we have to do more. One is we have to do something that’s even simpler than Vault, for all the other CAD users. I mean there’s still too much design data and you can’t find stuff easily.

I think many, many small offices, industrial designers and architects have gotten past the point where they need something more than just to help organise and search their data. They’re not ready for full Vault implementation.

“We’re doing the best job on the connection to engineering. The problem we have is in the places in which the enterprise information system is the determining factor about the rollout of new CAD products – really big places with big teams on multi-year projects.There’s government regulation about preservation of documents.

Secondly, some data could be online. I think the interesting thing is to do something that allows you to search and aggregate, whether the stuff’s online or local. Because one of the challenges of online is people are starting to have 14 places where they store their data – Google docs, Picasso, Flicker, drop box or Live Mesh.”

Autodesk demonstrated an un-named application in the main stage presentations at Autodesk University which did something similar to the product specification that Bass alluded to in our conversation.

Called Project Blueglue, he told us that it was being developed by the Architecture, Engineering, Construction (AEC) development team.

So what about PLM? “I think it’s probably a combination of two things. As the most outspoken critic of PLM, I have changed my mind in a couple of ways. I think PLM, by some vendors, has now reached the point of being usable, but not by all of them.

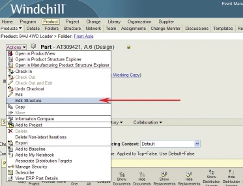

“If I had to categorise, it looks like (PTC) Windchill is having successful implementations. Not uniformly, but you can find instances where it works. I think (Siemens) Teamcenter has always worked to some degree, but it’s long in the tooth – everything about it is 20 years old and it’s not getting newer. It seems to be getting more convoluted and it’s messy, but in the places where it’s baked in, it’s baked in.

“I think you know the Dassault guys are having the greatest trouble with PLM. I think it’s somewhere between four or five failed attempts [at developing products], and dozens and dozens of customers who have failed implementations. It’s actually hard to find successful implementations.

When they screwed up SmarTeam, and they screwed up PDMWorks – every one of them is just a mess. So I’d say PTC has done a good job of getting away from saying a PLM system is something that can do everything.

I think the vendors originally started with this idea there was ‘Ginsu knife’ and then they finally said: ‘Yeah, no it doesn’t, it actually does only a handful of things, not everything,’ and so they’ve concentrated on the benefits that are more repeatable. I think Windchill’s probably done the best, Teamcenter’s the most installed and Enovia is the most confused.

“We’re doing the best job on the connection to engineering. The problem we have is in the places in which the enterprise information system is the determining factor about the rollout of new CAD products – really big places with big teams on multi-year projects.There’s government regulation about preservation of documents.

It’s a really different kind of problem found in military, aerospace, a little bit in automotive. We need the answer and the big choice is there are established vendors who do well with ‘on premises deployments’, all the ones we just talked about, versus whether or not we go for more of a deployment in the cloud.

“You’ll see us doing more but the real limitations placed on our business are in places where it’s not our software that’s deployed there. We could build something ourselves, we could work with a number of vendors, we just do just the interoperability, we could resell other products. But I do think we need to do something on the larger PLM.”

CAM

Talking about Autodesk buying a PLM product, or even co-licensing something like Windchill brought us to discuss the amount of consolidation that has happened in the past within the design tools community. Have we reached a point where the mergers and acquisitions will slow or continue?

“In some technology industries you can see this natural progression,” said Bass, “For example I am unconvinced that UGS will forever stay inside Siemens. Just like it didn’t forever stay inside EDS.

You know the entire time it was there people told us, said what a great idea it was to be there. Until the day it wasn’t, and then went to private equity. And then it was great to be stand-alone, until it wasn’t!

“When it gets more to individual ownership, then the decisions become much more personal and what Jack [Dangermond] decides to do with ESRI or the Bentley brothers decide to do with Bentley, it’s not quite the same. Dassault Systèmes is a family owned business to some degree and I can’t imagine, you know, big Dassault ever shedding any part Dassault Systèmes.

“I think the CAM market is right for consolidation, although I’m not sure if any of the technology has quite reached the right point. One of the things I’m very interested in is trying to start using tools and techniques like Fusion for the CAM market.

I think the CAM market is one of the next ones that needs an overhaul, in terms of capability. Most of the software there is just too difficult for most of the people. I think the CAM vendors have mostly focussed on the difficult part of the problem for them – 3-axis, 4-axis and 5-axis. A very hard problem and some good work done on that.

The bridge between what you have as your CAD model, and how you do that is incredibly difficult. And I think that’s a place where you will see consolidation.”

The cloud

The majority of the main stage was devoted to the benefits of cloud computing, or ‘infinite computing’ as Autodesk is now calling it.

The industry has been saying that applications hosted on the cloud will be cheaper to own as there will be little need to own expensive workstations, as everything is processed on a large remote server.

Will cost of ownership get cheaper with the cloud? Bass wasn’t convinced, “I’m not sure that turns out to be cheaper. You will get more, but not obviously cheaper.”

“It used to be, you’d look at the back of PC magazines in the US and $2,500 was the top of the line, whoever was on it, whether it was Gateway or Dell, or HP at the time. $2,500 bought you the best.

Nowadays, if you want to spend $2,500 on a PC, you know you have to start getting into double graphics cards, enormous amounts of memory, water cooling….I spend a lot of money on PCs, because I have this thing about noise. So I buy the quiet PCs. And I always want the multi-cores, and I still can’t get anywhere near 2,500 bucks…You can’t do it!

“If you ever want to see subcultures, there’s a place, endpcnoise.com. They sell every possible component for making silent PCs and they’ll custombuild them for you too. They have these big heat syncs, big copper tubes and lots of the cases have fins on them to dissipate the heat. So there’s this whole subculture, people who buy passively cooled PCs.

“You know what I hate is being in a room with three or four computers, they’d be 70 decibels, and here I am just sitting in my office by myself! It’s just a racket! I can’t think! I did try for a while having them in the basement with long video cables and for the keyboard but then, where’s the DVD!?

Meanwhile back on the ‘silent’ cloud, Bass gave us an example of how it will change the way we design. “Moldflow is our most computationally intensive application. You know, you get a good size plastic injection mould, calculating the flow through it.

It can be somewhere up to 24 – 48 hours of CPU time on a machine with eight CPUs, and while it doesn’t fully use eight CPUs, it tries. “So we did two different things, we moved into the cloud and instead of the eight CPUs we used 64 or 128, or whatever we feel like. You get some kind of scaling and a definite improvement in time. But two things we found out when we ran stuff on the cloud, is it ran much faster and we could run bigger jobs than people ever had on their desktop.

So some of the machines have 128GB of RAM and nobody was ever allowed by their boss to go out and buy a machine with 128GB of RAM! “Next we said that’s not really good enough. So then we went to a second technique of specifying some of the parameters around it, so that you do multiple calculations.

However, they still may not be where the gates really needed to be. So rather than waiting for someone to come in and look at the result, why don’t they sub-divide it and look at the place that gives the

best results.

I will have some measurable criteria, I will then, within that, probably subdivide it further to move it around. So rather than waiting for you to come and try a couple of answers, until you get an answer that crosses the threshold that’s acceptable, let’s just go find the answer. So we did that. And so we moved it to where the computer says: ‘I know what you’re trying to do.’

“The last thing we did, we took the fluid solver out of Maya, which is mathematically incorrect. It’s not quite right because it was only meant to kind of trick you visually, but because of the way it was done, the errors on it are known. So we took this gaming technology that’s meant to run in real time and enabled real time fill of the plastic.

For a cell phone designer this would mean that every time a change is made, it goes off and runs the plastic fill. It may not be perfect but it won’t take three weeks to figure out how to manufacture. The errors are tiny. They’re measurable errors.”

www.autodesk.com

DEVELOP3D talks cloud, PLM, CAM and Sudoku with Autodesk’s CEO