While many products start their life as virtual models in a CAD system, there are many industries that need to scan in real-world objects to either start their design process or assist in the creation of new products. While in the world of CAD, intelligence is created as part of the process, scanned in point clouds are just a bunch of dumb points. Geomagic has made huge strides in developing software which can recognise physical features in point clouds and provide designers with tools to intelligently manipulate scanned data, as if it were created in CAD.

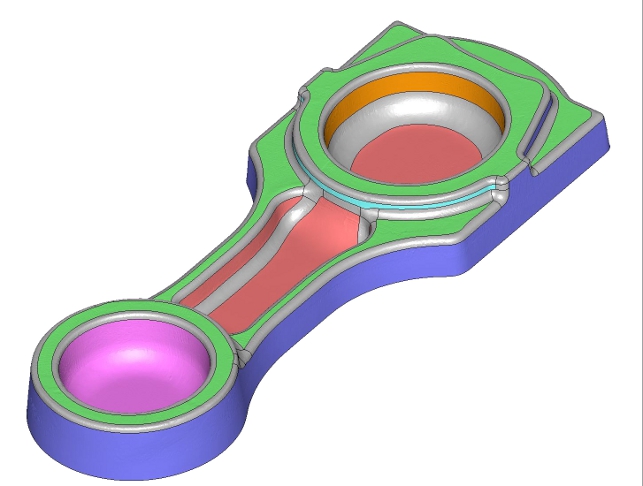

The Fashion module of Geomagic Studio 10 can be used to classify surfaces on a digital model according to their basic shapes. For example, planes, cylinders, free-form and others.

At this year’s Congress on the Future of Engineering Software (COFES), held in Phoenix Arizona, I talked with Ping Fu about the emerging direct modelling technologies (Synchronous Technology from Siemens, the SpaceClaim modeller and PTC’s acquisition of CoCreate) and movement away from parametric feature and history trees. There she told me of a technology called Fashion, data that was in beta, which would offer modelling capabilities to rival existing CAD systems, yet could make real sense of scanned-in point cloud data. Ping Fu went on to explain why she thought that raster data was the ultimate CAD format, as with emerging technology, intelligence could always be interpreted and added later, when required. Geomagic’s Fashion technology could make raster the ultimate achievable format.

Martyn Day: So how did Geomagic’s Fashion technology come about?

Ping Fu: Fashion technology originally came out of the Hungarian Academy of Science (HAS), which has been very well known in terms of its mathematical prowess on analytic geometry and discrete geometry. They have a team there that is world-renowned for research into that key area. They had been working on this really tough intelligent raster technology for a long time, eleven years or so.

Two years before we ended up buying them, the HAS team were working with BMW on tools to manipulate scanned physical models, as BMW wanted to be able to bring in car surface data from scans into their CAD system but in an intelligent way. So the team worked on prototyping with BMW for almost a year. While I was at Euromold I talked with BMW, who is a customer of Geomagic, and their Head of R&D came up to me and said “I really like Geomagic Studio, but I don’t like just putting dumb solids into our software.” We know this from feedback from many customers and have been looking into how to make scanned data more CAD-compatible but it’s an exceptionally hard thing to do and we hadn’t found any technology that could do this easily.

My contact at BMW explained what they had been working on and how they thought it would fit well inside our Studio product and he introduced us to this development company called CADMUS in Hungary, a firm funded by Tamás Várady, who is a big name in our industry. CADMUS was a development company (not a product company). My husband, who works in development at Geomagic, also has links with the Hungarian Academy of Science as he knows a lot of mathematicians there, and also knows Tamás, so I said let’s go to Hungary! We went over, had a demonstration of what they are doing and were totally blown away.

First, I realised that CADMUS was not a product company, this was a research group and they’d been working on this for a long time and they were very ‘gung-ho’ because BMW really wanted this technology so they thought it was going to be a huge success. I talked to Várady and he wasn’t willing to sell but we got a consulting agreement and we gave them some direction on where we wanted them to develop. A year later BMW stopped funding the development because BMW wanted a real product and what was being created didn’t work with any of the products the company was using.

While it’s a great technology, it was just technology. CADMUS signed up a reseller in Japan – and they travelled to all the automotive companies, Toyota and Mazda and again, while people loved the technology, the reseller couldn’t sell any.

I approached Tamás again and said you’ve got a great technology that could become a great product, come join us and we will purchase you and be part of Geomagic and at that point he was willing so we bought the company.

When I finally got the company I realised that even though Tamás promised me that the technology was 50% there it was really only 10%! Especially in terms of the kind of automation we wanted, and even though the technology is beautifully, mathematically complete, the process was too manual for a lot of applications and it still followed the traditional ICEM/Alias approach. Certain things are automatic but most work was still manual so we ended up spending four years basically putting their expertise and our expertise together and re-thought the whole thing. And so that’s where the Fashion comes from!

Ping Fu, President & CEO, Geomagic

So Fashion, in terms of mathematics, was an eleven year prototype development and probably 20 years of R&D by the best mathematicians in the world, combined with the strength of Geomagic. We have 28 PhDs in the company and we are very strong in the image-based processing approach that is very automatic and they are very strong in the CAD recognition almost like optical recognition which is a different kind of technology. To put those two together to make the product easy to use was actually very hard. Even the first version of Fashion is only the beginning of it because we tried to put something out there to see how customers use it and to provide feedback. Since then we have released 2 service releases and then the third one is due out in October – this will include significant improvements on the first version.

We have all this technology but are not sure what kind of workflow it should follow. There are diverging opinions on who wants what. The designer wants ultimate flexibility (like the surfacing people) then the CAD designers want some flexibility not so much but typically don’t care about the surfaces. Then you go to the CAE and CAD guy and they really want it all to be automatic within a certain tolerance but the CAE user doesn’t want editing. An inspection user just cares about CAD nominals.

So how do you take a really good technology and then put in the workflow that is natural to each of those groups of people who have a different requirements – we really don’t know. We currently don’t know where to cut the line, so that’s why we released the Fashion earlier just to get feedback so the version that you see, I still call it a beta. We didn’t charge people, initially we made it free and we got tremendous feedback from the market place – everybody loves it. Even when we did charge for it, we exceeded sales expectations.

If this (Fashion) takes off then this would be beautiful for us. Because the direct modelling or direct editing of models inside Unigraphics and Catia V6 means our end model can go directly into those CAD systems and everyone can edit it. Ping Fu, President & CEO, Geomagic

MD: Which industries are really taking Fashion technology up?

PF: Automotive, Turbine design in Aerospace, Maintenance/ Repair/ Overhaul (MRO), Mould and tool manufacturing. Automotive body design is where it has really been taken up the quickest. We sold a lot of seats to body design shops. As you might expect, Alias (Autodesk) is very excited about our technology too. It has an installed base of 12,000 users who could potentially all be our customers, so Alias is going to be our distributor.

MD: So how did the deal with Autodesk come about?

PF: Autodesk really had a bigger vision than anybody else and had a more well-spread application area that we can take advantage of our DSSP. Autodesk caters to architecture, traditional CAD, mechanical engineering, manufacturing and entertainment, so all of their product line could leverage a technology like this and I think Autodesk is really looking at DSSP as a fundamental digital platform for all of their products.

MD: There has been a big buzz around direct modelling tools of late with Siemens PLM Solutions launching Synchronous Technology, a new modelling tool from SpaceClaim and PTC buying CoCreate. It seems to me that raster data that can be converted back into editable CAD elements is moving with the same revolution.

PF: If this takes off then this would be beautiful for us. Because the direct modelling or direct editing of models inside Unigraphics and Catia V6 means our end model can go directly into those CAD systems and everyone can edit it. And at the same time, our Fashion technology can reconstruct and provide information for the history tree. That said, their direct modelling capabilities within their own modelling tools cannot communicate very well with the traditional data created in the CAD side of their programs.

It used to be that ‘dumb’ models made from scans weren’t so useful. Now with direct modelling, even dumb models are useful!

Most vendors are doing direct modelling for digital prototyping purposes, they have to be able to take different models in from various sources but they do not have the Fashion technology to take one type of model and put it into the other type. This means I can give them two things. I can give them models that they can now edit very easily and I can also give them a typical CAD structure that they can drop into their operational history tree.

It’s now the case where both of our model types have become more useful to traditional CAD users. It used to be that ‘dumb’ models made from scans weren’t so useful. Now with direct modelling, even dumb models are useful!

If you want a featureless model to use direct modelling on, Geomagic can give them that almost 100% done – users can just go in and edit it. Looking at working on a CAD model with built-in features, with Fashion we can now give them the structure that’s about 80% there, and users can finish it in their CAD systems using their normal tools. So Fashion is more valuable to CAD as it’s a new capability and this is one of the reasons why we are getting a lot of attention from the big CAD companies – Autodesk, Dassault Systemes, PTC etc. What we have is far more valuable.

Conclusion

The CAD industry is heading towards a time where the tools on offer provide new levels of freedom for modelling. Traditional methodologies and limitations appear to be rapidly melting away. Geomagic’s innovation with Fashion technology appears to cross an important boundary, where it’s hard to consider any model or physical data as dumb, as you will always be able to accurately get it inside any CAD system and be able to intelligently manipulate it to create the next version or a brand new product.

This opens up many possibilities for moving data around previously incompatible systems. Also the big problem of archiving legacy data looks like it could be about to be cracked. If you have a physical entity you can scan it and reconstitute an intelligent CAD model. If you have a dumb solid model with no features or history, you can now get software to make it useable.

This does open questions over Intellectual Property but copying designs has been with us pre-CAD for centuries, it’s just that now scanning and digital automation may make it a faster process.

It’s time to start removing old mentalities over what is and what isn’t possible with CAD and Geomagic’s Fashion Technology is certainly worth further investigation.

Martyn Day talks to Ping Fu, CEO of Geomagic about Fashion Technology