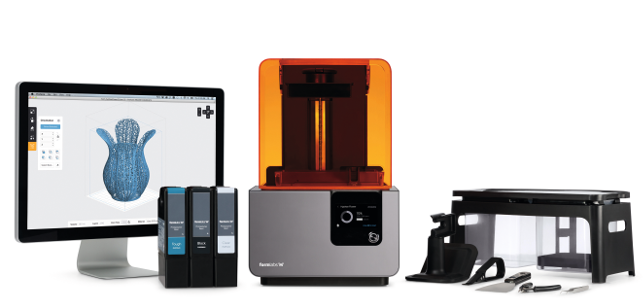

The Form 2: machine, materials and finishing kit have all been redesigned

When Formlabs launched the Kickstarter campaign for its Form 1 machine back in 2011, the Somerville, Massachusetts start-up transformed how the design world looked at 3D printing using stereolithography (SLA) – and broke records for crowdfunding into the bargain, raising $3 million in three exhilarating weeks.

Why the buzz? For the uninitiated, the SLA method used by the Form 1 uses a light source to ‘cure’ layers of resin in 3D models. Invented and pioneered by 3D Systems’ founder Chuck Hull, SLA was previously seen as a heavyweight industrial process with a hefty price tag to match.

It certainly has its advantages. SLA’s scope for supporting a wide range of material formulations, varying buildsize machines and ultra-fine-detail models has made it a mainstay of the rapid prototyping industry for decades. But, until the arrival of the Form 1, the technology was heavily patent-protected and the market was effectively closed to all but a few. Even entry-level machines typically costly tens of thousands of dollars.

Formlabs changed all that. Established by a group of graduates from the Massachusetts Institute of Technology (MIT) with some serious venture capital backing, the company took advantage of the expiration of 3D printing patents to create its technology. Within a year of its Kickstarter campaign, Formlabs was shipping the Form 1 to backers.

But while previous SLA machines were aimed at the professional designer and engineer, and therefore priced for corporate sales of around $20,000-plus, the Form 1 was a desktop machine that retailed at a shade over $3,000. It was smaller, too, fitting snugly onto desktops, but with the same ability to build high-resolution models from lightcurable resins.

In June 2014, Formlabs went on to release an updated version, the Form 1+. Addressing some niggles that had come to light with the original machine, the release of this second model saw the company starting to be taken seriously in the professional space.

Fast-forward a year and by mid-2015, with several hundred thousand units sold, it had become clear that Formlabs – unlike many other 3D printing companies before it – was here to stay. So what would the company do next?

The answer came in September, with the launch of the Form 2. From the outset, this was clearly a new chapter in the Formlabs story. With re-worked internals, a new form factor, a larger build volume and a brand-new build process, the Form 2 looks good on

paper.

And with DEVELOP3D hoping to get its hands on the machine shortly, this seemed like an opportune moment to catch up with the folks behind it and discuss the machine’s evolution.

Inspiration and drive

So what has it taken, in terms of inspiration and drive, to push the boundaries of an already successful project? And how exactly did the Formlabs team get to the point of being a credible, viable business, in the first place?

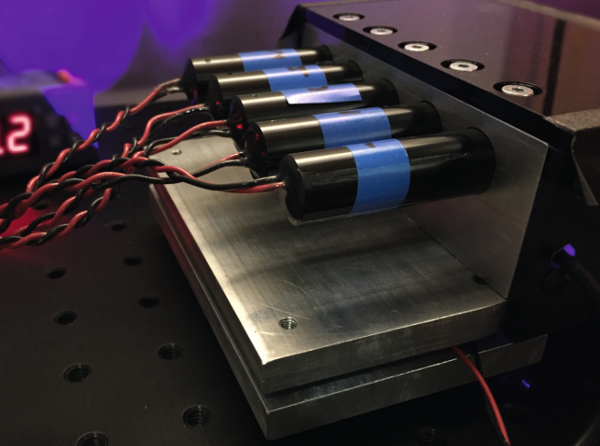

Formlabs has redeveloped its materials system, with the option of auto-feed from pre-filled cartridges

“When we started in 2011, we took the technology of stereolithography, which had been around for 30 years, and made it available for a wider group of people, to enable professionals to be able to do their job,” explains David Lakatos, product lead at Formlabs.

A big element of the Formlabs message, he says, has been that it’s no longer necessary for designers to share an expensive machine with a large group of people – or to work with a service bureau that has a machine of its own.

This is a capability that designers can afford to have right on their desktop. But in order for Formlabs to orchestrate this shift, a couple of key factors have needed careful consideration, he says.

“We had to figure out how to make it good enough and affordable enough, much of which focuses on the galvanometer system, to make sure that stereolithography worked at that price point,” he says.

This is important, because the galvanometer is the mechanism that directs the laser beam from its source to the resin in the build tray, tracing out each layer. In traditional SLA machines, it’s arguably the most expensive part to manufacture and maintain.

After that, the company found “another bunch of challenges”, says Lakatos, which it addressed in the Form 1+ machine. In the process, it built its team up, bringing in new employees who were experienced in control systems and improved individual components.

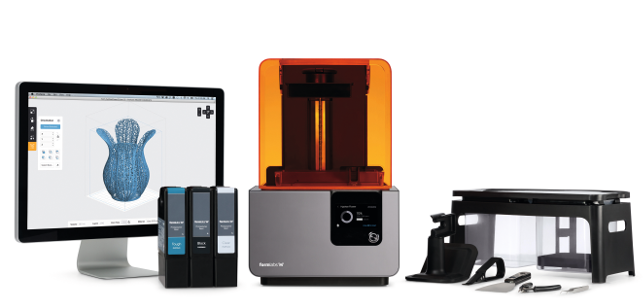

The current line of resins: several colours and tough, flexible and castable options available as well

When it came to the Form 2, he says, “the most important [things] that we wanted to improve… were reliability and consistency. We wanted to build on what we already did well, which is high-quality, high-precision prints, but we also wanted to pair this with [the ability] to print whatever you want to, whenever you need to.” This expansion of Formlabs’ goal, he explains, led the team to define four key areas of focus for the Form 2.

1. Build process

“Let’s start with the new build cycle and the new wiper,” says Lakatos. “If you look at the Form 1+, it’s a hinged peel mechanism. So we tilt down one side of the resin tray to peel away each layer. This puts quite a lot of force on more fragile models and can cause degradation of quality.”

With the Form 2, a new sliding peel mechanism reduces those forces significantly, to give a higher quality part.

“The wiper goes back and forth between every layer, which ensures that there’s always a perfectly clean layer of resin left on the build tank, that’s fresh and free from any particles,” Lakatos explains. This also extends the resin tank’s longevity, he says.

FormLabs’ reputation is built its machines’ ability to deliver highresolution, fine-detail models

From our conversation, it would also seem that the team learnt some valuable lessons from the environments in which its first-generation products were used. Although it’s not widely known, photo-curable resins behave well only within a pretty narrow temperature band. In colder climates or draughty workshops, low temperatures can wreak havoc and lead to failed builds.

“In stereolithography, temperature matters a lot – both mechanically and for the chemistry in the resins and the build process,” Lakatos acknowledges. “It doesn’t matter where you are. You want the same, consistent build quality.” The new Form 2, as a result, has a temperature-controlled build chamber.

Another issue that arose with the Form 1 and Form 1+ was the density of parts. While these machines excel at building fine-detailed models, users who were prototyping more chunky parts consistently ran into problems.

The new wiper blade, in combination with a more powerful laser and bigger build volumes, should tackle these issues, says Lakatos. “The 50% more powerful laser enables not just faster printing, but also enables us to explore new chemistries in the resins.

We increased the build volume [by] 40%, so you’re able to print much larger and more dense parts, and that gives you a lot more flexibility,” he says.

2. The galvanometer

As discussed already, a laser source and a galvanometer lie at the core of all the Formlabs machines. For the Form 2, the company looked to improve the existing mechanism.

This threw up some significant challenges, many of them tied to cost, Lakatos explains. With SLA, there are typically two types of machines.

First, there’s projection SLA, where the price is difficult to negotiate, because machines need to include a projection device. Second, there’s precision SLA, where quality can be compromised as build size increases, because of limitations as to the number of pixels that can be applied to a task.

What Formlabs has achieved is precision SLA that scales, even as costs stay low. “We’re particularly proud of this achievement,” he says.

“With laser-based systems and quality galvos, you can do much more compared to some stereolithography systems that use a projection system. At that price point, the typical galvanometer systems are used in laser light shows and other applications that aren’t focused on precision.”

3. User experience

With the Form 1 and Form 1+, users had to pour the resin into the tank before they started to print. That could be a messy, drop-by-drop business – and it led directly to the development of the Form 2’s resin delivery system, based on pre-filled cartridges.

The Form 1 and Form 1+ struggled with dense, chunky parts, but this has been addressed in the Form 2 with a higher powered laser unit and new build mechanism

“This is something I’m excited about, personally,” says Lakatos. With the resin cartridges, the machine is automatically filled, he explains. “The whole thing is taken care of. There’s no pouring of resin – it’s all automated.”

The cartridge system doesn’t mean that Formlabs is closing its ecosystem or seeking to dissuade users from experimenting with other materials, he stresses. The Form 2’s resin tanks can still be filled with other materials in ‘open mode’, enabling users to use third-party resins.

The company has also focused on improving the instructions and prompts that the machine gives its users, he adds. “All the interactions with the machine, such as the touchscreen and the queue manager, are real-life examples of where we listened to users of our previous machines.”

These improvements, he says, should make life easier for both individual users (an engineer at a small company, for example) and people working together as part of a team.

“For them, the new functionality focuses on using the printer as a group – to upload parts, print them when [the machine’s] free, get notifications when it’s started to print or has finished. They can also track progress online using the dashboard.” The dashboard, incidentally, can display the status of a single machine or a group of machines.

4. Low price

When the Form 2 was announced, a pretty simple fact escaped most pundits but stood out for a few: the price hadn’t risen dramatically.

In the brave new world of lower cost 3D printing, many are accustomed to seeing vendors start with cheaper models and then ratchet up the prices as capabilities improve. A good example is Makerbot.

But Form 2 launched at pretty much the same prices as its predecessors – a surprise to many. After all, it offers a lot more than them: larger build volume, more complex and robust optics, a more complex build process. So how was this achieved and to what extent was keeping down prices a factor in its development?

“We really don’t want to move up to a $10,000 machine. We wanted to build a better machine, for the same price,” says Lakatos. With an engineering team now nearing 50 people, Formlabs has more human intelligence at its disposal to throw at the problem, allowing it to concentrate more closely on details.

“With more effort, you can always push the price down and we found that having a bigger engineering resource really helped us with this,” he says.

Form design at Formlabs

One area of particular interest to DEVELOP3D is the aesthetic quality of all of Formlabs’ machines. After all, 3D printers have never typically been the most pleasing devices to look at.

The Form 1, by contrast, was something you’d be happy to see in your design studio – even setting its technical capabilities aside, it simply looks the part. And there’s now a Form 1+ in the London-based Design Museum’s permanent collection.

So how did the success of the initial machines drive the design of the next-generation product?

Lakatos explains that industrial design is central to Formlabs’ working process, but that engineering work leads in the early stages. The team has a strict policy of working on the internal and mechanical design first, and only then explores how the machine looks and operates.

With the Form 1, this process saw the machine move from a very different prototype to the final model. As Lakatos recalls, the “original, engineering-led design for the Form 1 was basically twice as long and half as high.

That was driven by the laser path. Our industrial designer Yoav Reches pushed to make it more compact and to make it what it is today.”

He continues: “We used the same principles with the Form 2. There were some additional constraints [introduced by] the slide-and-peel mechanism and the resin cartridge system, to pull those together and consider them in the final product.”

But, ultimately, he’s happy with both function and lookand-feel in the final product. “It’s a more professional-looking machine. It’s still very sleek, but it’s also very functional. It tries to be compact and, of course, it looks good on the desktop.”

Where next for Formlabs?

Formlabs has no intentions on resting on its laurels at this stage.

According to the company’s CEO Max Lobovsky, the first priority is to ship Form 2 and get feedback from its users – but his vision of future developments at the company goes far beyond its roots. “At a high level, we invented desktop stereolithography and we’re leading that field today and want to continue to do that. That would be our biggest focus,” he says.

“But more broadly, Formlabs is interested in becoming a tech company that builds tools for designers and engineers.

I think we have a unique combination of brilliant engineers, building cross-disciplinary products that need to go all the way to an end-user experience, as well as market to, and support, designers and engineers.”

The company has several products in the works that, right now, it’s not ready to announce. “But we’d like to go beyond stereolithography,” Lobovsky teases. There is more to come, then, from Formlabs – and it will have to work hard to impress, given how far it’s come, and how quickly.

Formlabs test processes

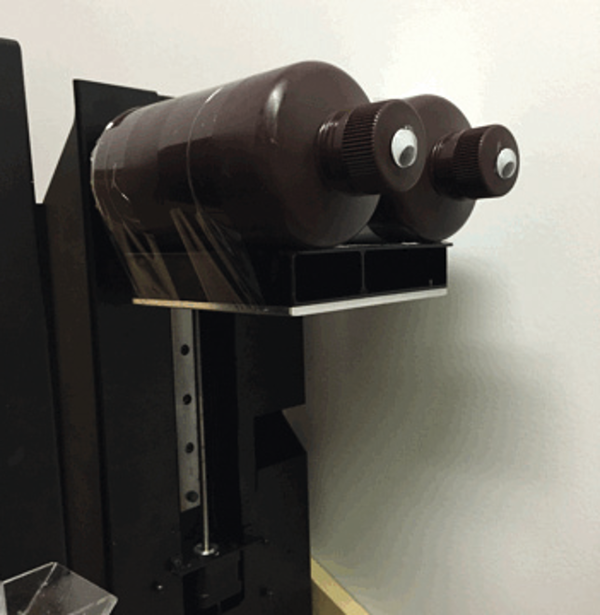

1 Laser focus

At the heart of any stereolithography (SLA) 3D printer is its lasers. The Form 2 has a 250mW precision laser that traces an optical path through the printer, curing layers of photopolymer resin.

First, Formlabs tested the optical power of the lasers. To be able to simulate thousands of hours of printing in a shorter period of time, lasers were run at higherthan-normal temperatures.

In development and in production, Formlabs runs a beam profile of every single laser. It uses cameras and sensors specifically designed to analyse and record laser spots, in order to ensure each beam achieves the right size, shape and high-power metrics.

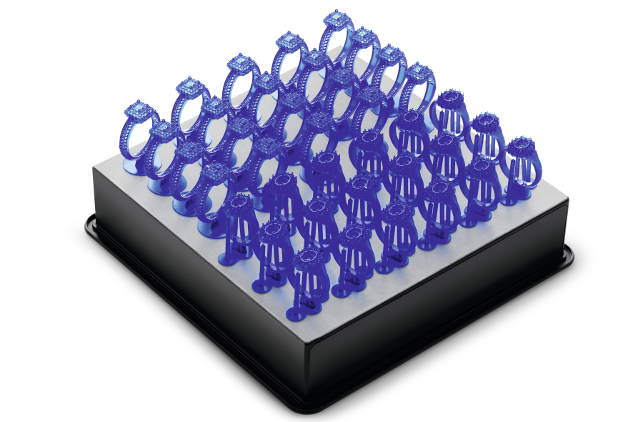

2 Precision galvanometers

One of Formlabs’ most ambitious aims in building the Form 2 was to design and manufacture its own custom galvanometers. These are the very precise, rapid-response motors that guide the laser during the printing process.

For the Form 2, it needed a level of precision and reliability that it couldn’t find in off-the-shelf galvanometers, so it had to take on the challenge of building its own.

Though galvanometers are relatively simple in terms of function and part count, the real work lay in ensuring that the design was reliable and manufacturable. Design validation testing was an integral part of the development process.

In the galvanometer tests, the Formlabs team studied pointing accuracy, precision and stability. Tests exposed lasers and galvanometers to operational conditions beyond what they will ever experience in a printer.

During these tests, Formlabs drove the components at higher powers, faster speeds and higher temperatures for hundreds of hours, while monitoring their performance.

3 Lifting & sliding

The Form 2 has a few critical moving parts; the build platform that raises and lowers during the build process (also known as the z-stage), and the sliding peel mechanism.

Formlabs expects both of these subsystems to see a lot of use, so it wanted to test them for longevity.

It developed test rigs that ran on ‘infinite loops’, in order to identify when components would fail. Both the z-stage and the slide assembly performed so well that it eventually stopped the test after 4 continuous months and over 2 million slide cycles. That’s equivalent to over 500km (310 miles)!

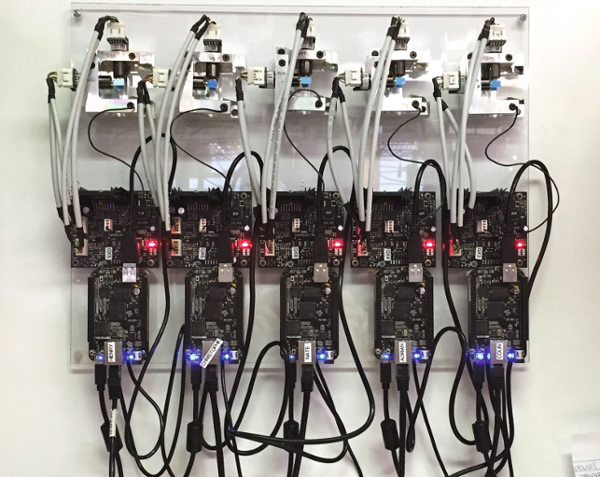

4 One system to rule them all

The final step in design verification testing is to fold all the subsystems together and test them extensively. The interplay between subsystems provides different challenges than the individual pieces functioning alone.

To ensure all systems worked well together, Formlabs ran over 50 system-level tests, ranging from electrical overloading and static shock to extreme environmental testing.

The Form 2 features an advanced optical engine comprised of lasers and precision galvanometers. The number one enemy in optics is dust. To test the Form 2’s dust resistance, Formlabs placed a printer in a sealed chamber and blasted it with talcum powder for six straight hours.

At the end of that ordeal, the Form 2 still printed at full performance. Technically, this means you could use a Form 2 in the Sahara desert, if you managed to find a power outlet.

Formlabs reinvents desktop SLA – again

Default