Peloton – Its new Tread product takes the company’s blend of sleek hardware and advanced software a few steps further

Even those of us who have gone to the trouble and expense of installing fitness equipment in our own homes will agree that it takes discipline to actually use it on a regular basis. We start with good intentions, but as the novelty wears off and enthusiasm wanes, that equipment often becomes little more than an expensive but neglected ornament, gathering dust.

In many ways, the prospect of a gym-based fitness class, where you have the motivation provided by an instructor and the ‘we’re in it together’ camaraderie of fellow class members, can seem more attractive. And, of course, in a class, you can’t bunk off halfway through to lie on the couch. At the same time, finding a fitness class that fits into our busy family, work and social lives can be a challenge.

This is exactly the dilemma that Peloton co-founder and CEO John Foley was facing back in 2011. His fitness class of choice is spinning, which involves pedalling along on a stationary bike as an instructor guides you through a high-intensity workout. But he was frequently unable to schedule time to make the classes. Thinking that there had to be a better way, he hatched an idea to recreate the experience of a spinning class at home.

With an engineering degree and a business background, he left his role as president of Barnes & Noble’s e-commerce division to establish his start-up in 2012 and began assembling a small team. He called his new company Peloton, a cycling term that refers to the main group of riders at the front of a race. The idea here is that, as part of a peloton, you’re more efficient and so, as a group, you’ll go far.

In his mission to disrupt the at-home fitness market, Foley clearly had no intention of being a laggard or an also-ran. But he knew that his stationary bicycle concept would need to offer far more than just hardware. The tech-focused goal was to deliver fitness as a service, with content and community all part of the customer experience.

A touchscreen fitted at the front of the bike, he decided, would stream both live classes and previously recorded classes on demand. These classes would be filmed in a studio in New York with a few riders and a fitness instructor up front. Instructors were carefully selected, as they would be just as important to the Peloton brand as the bike itself.

As a class gets underway, onscreen performance tracking metrics allow at-home riders to monitor not just how they are doing, but also how they stack up against other participants who have tuned in for the class, via a real-time leaderboard. Instructors look directly into the camera and offer encouragement to those at home, whose names appear on a screen attached to their bikes.

The Peloton Bike launched in 2014 at a price of $1,995, with an added monthly subscription charge of $39 for live and on-demand classes. It’s arguably a costly sum, but customers took to it in their droves, resulting in a huge fanbase, with some more addictive types tuning in for four or more classes a day. They heaped praise on Peloton for its immersive, motivating and communal experience.

Post-workout, many have taken to the Peloton Facebook group for virtual high fives and back-slapping.

Peloton -new take on the treadmill

Having successfully raised hundreds of millions of dollars in investment funding and being not averse to taking risks, Foley soon decided that Peloton should branch out into the treadmill market.

In 2018, the company launched the Tread. Unlike traditional treadmills, the Tread offers circuit, bootcamp, strength and even yoga workouts, both on and off the machine. “This product’s focus was bootcamp-style fitness, so we aimed to deliver a full-body experience, rather than just a running-only experience,” explains Mark Kruse, Peloton’s lead industrial designer on the Tread.

Kruse joined Peloton in Spring 2016, along with other staff recruited specifically to work on the development of this new product. Whereas the original Peloton bike was developed with the help of a product design consultancy, the Tread was to be fully designed and engineered in-house.

“We did a lot of market and user research prior to the design phase kick-off, so we knew what type of exercises we wanted to accomplish with this machine, as well as the different features we wanted to incorporate,” says Kruse.

At this early stage, the team also engaged with Peloton’s contract manufacturers, which are based in the US, Italy and Taiwan, to gauge manufacturing abilities and limitations. This helped create a rough bill of materials (BOM) and budget for the project.

From here, team members from various disciplines across both hardware and software came together for early brainstorming sessions. Describing the Peloton approach to design, Kruse says: “The hardware and software teams are intertwined from the beginning and we each own equal parts of the design phases. We either work directly together or perform weekly, sometimes daily, check-ins to ensure we are on track and marching to the same beat.”

Having determined a range of feature sets and use cases, the design team started sketching concepts. As a treadmill is a fairly large, architectural product, they quickly moved into Solidworks to create rough full-scale CAD models, which helped in these sketching and ergonomics studies.

Before any further refinement was carried out in CAD, the team created full-scale mock-ups using foam core, 8020 aluminium bucks, wood and so on, to help find the right architecture. “When designing physical fitness equipment, working in full scale is 100% necessary. The Bike and the Tread are such ergonomic-driven machines, and involve the entire human body, not just a hand or a foot. You need to nail down sizing and distances to each touchpoint before getting into the details of each component,” explains Kruse.

Paired with this rough works-like model, the designers started evaluating surfaces, graphic break-up and lighting with their rendering tool, KeyShot. With these visualisations, they could then present concepts to other team members and stakeholders involved in the project.

It’s during these meetings that Peloton’s management team will often see concepts for the very first time.

Rather than breathing down their necks, says Kruse, the company’s leaders give design and engineering teams (both for hardware and software) the freedom to create without having to report back all the time. “This implicit trust is truly appreciated by our team and makes the moments when we present to them a really fun type of ‘show and tell’,” he says with a smile.

Peloton – importance of prototyping

When one or two concepts have been fleshed out, the design and engineering teams will typically share them with contract manufacturers. From here on in, as the selected design is taken through the development process, they are in regular, often daily, contact. “It is important to maintain a good working relationship with our contract manufacturers and to stay involved throughout the production process to ensure our quality is met,” says Kruse.

To make every detail of the Tread as perfect as possible, the design and engineering teams took prototypes through many cycles of testing, evaluating and improving until they were completely satisfied. 3D printing was crucial in enabling them to do this. “3D printing is by far one of the most useful and cost-effective pieces of equipment in our R&D lab. We have two Formlabs printers for SLA and four Makerbot printers for FDM. Of course, 3D printing does not achieve all our needs, so we do some wood, foam and metal fabrication as needed.”

With a design shaping up, KeyShot is used to analyse surfaces, colours, materials, graphic elements and branding. According to Kruse, being able to work through several different colour and finish options in a matter of minutes not only saves time but also money, insofar as these virtual prototypes mean that not as many physical prototypes need to be made.

The physical prototypes that are made are put through many rigorous tests. “We only perform these tests under worst-case scenarios: heaviest user, fastest speed, maximum incline, etcetera. Not only is the entire machine tested, but so are each of the individual components separately to meet our standards,” says Kruse.

During the prototyping stage, the electronics integration team will work with the designers and engineers to integrate the early software for the controllers and the consoles into the prototypes. And, just as the design team is working through its various phases of prototypes, so too is the electronics integration team, which also makes use of 3D printing and Arduino before it lands on the final production components.

With the pilot build phase complete and the button pressed on mass manufacture, the design team creates all the early marketing materials in KeyShot, including video and hyper-realistic imagery, which is very useful in helping them debut the product before it physically exists.

“When our community gets that first glimpse of the new product, they see the details and the experience they can expect from us, we begin to see a lot of positive feedback and demand for the upcoming product.

Obviously this translates to actual sales, which is extremely exciting for us to see,” says Kruse.

Launch of the Tread

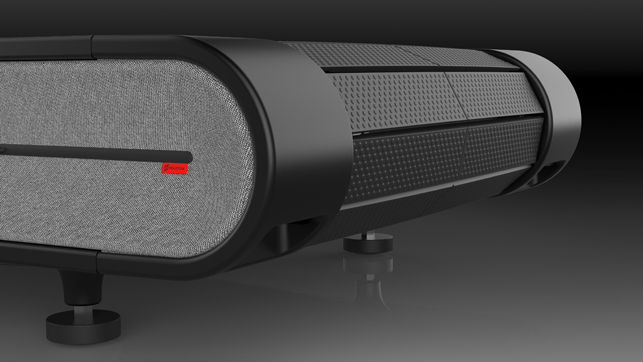

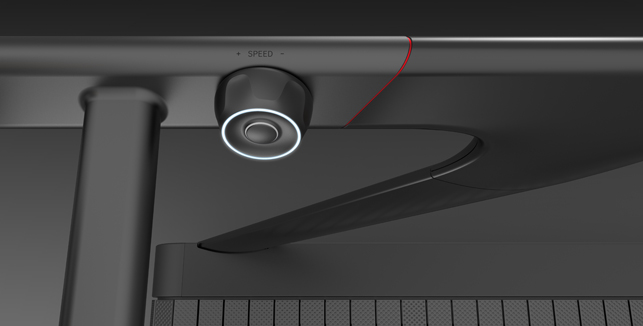

The big reveal of the Peloton Tread took place at the Consumer Electronics Show (CES) in Las Vegas during January 2018. Featuring an all-black carbon steel body, belt technology with 59 individual shock-absorbing slats, a 32-inch HD touchscreen, a soundbar, and two rotating dials – one for incline and the other for speed – visitors had the opportunity to see, touch and try the Tread out for themselves.

Kruse was on hand during the event to talk through various features with visitors. He admits that he couldn’t be more proud of the product and how the design and engineering teams across both hardware and software have been able to achieve the goals set out from the beginning without compromise. “I would say our biggest achievement, from both a hardware and a software perspective, was enabling this seamless control of the deck via touchscreen controls, as well as the dials, simultaneously. It really creates a unique and ideal user experience for our customers,” he says.

And, judging by the reviews following the shipment of the first products towards the end of 2018, customers are very pleased with the end result, despite the rather hefty price tag of $3,995, which is double that of the Peloton Bike.

Peloton has been pulled up on cost by some detractors. Its response is that what customers are getting with this premium product is value. “Compared to the Bike, not only is it about twice the size, with twice the screen and about ten times the complexity as a machine, but it also offers thousands of classes, from running to strength training to floor workouts, still for $39 a month and all from the comfort of your home,” says Kruse.

New products and services are being launched in the near future. The most recent of these is the Peloton Digital App, which offers access to over 10,000 classes, but does not require Peloton’s hardware. It’s this kind of first-out-the-gate innovation that will ensure the company remains a frontrunner in the fitness equipment market.