In April, one of the most talked about (usually in hushed tones) software companies in the design and engineering space finally went public with its beta offering.

If you’ve missed the rumblings in the last two years, here’s a quick catch up on Onshape and its eponymously named design tool.

Originally founded as Belmont Technology, Onshape is headed up by Jon Hirschtick and staffed by a mix of the original SolidWorks development and business strategy folks that eventually sold out to Dassault Systèmes back in 1997.

Since the news emerged that “the band was getting back together”, the 3D CAD world has been talking about what the company might or might not do. But, one thing has been certain, with $64 million in investment capital in its coffers and a killer team, something interesting was brewing.

Early last year, much of that plan started to emerge, under a strict NDA that has now been lifted. While we’ll be taking a deeper look into what the tool can do in the May issue, it’s worth a quick overview here.

What is onshape?

Onshape (the product, not the company) is a cloud-based affair, aptly representing where things are heading in the software world.

Technically, it’s comprised of two key areas, 3D design/engineering and the data management and collaboration backbone it works within. The two are tightly interrelated and fully integrated.

Onshape doesn’t have a software install. It’s an entirely browser-based system with the only requirements being a WebGL browser and a decent amount of RAM. No heavyweight graphics cards and no powerful workstation. As long as it meets the browser specs, it should just be a simple case of logging-in and getting started.

All of the data resides on the cloud, in fact, all of the calculation happens there too. So, essentially the user drives Onshape remotely.

This means that there is no heavy synchronisation of data but it also means that, at present, if the web connection drops, access is lost.

The good news is that everything up until that drop is automatically on the cloud. So the user can pick it up again as soon as the connection is reestablished.

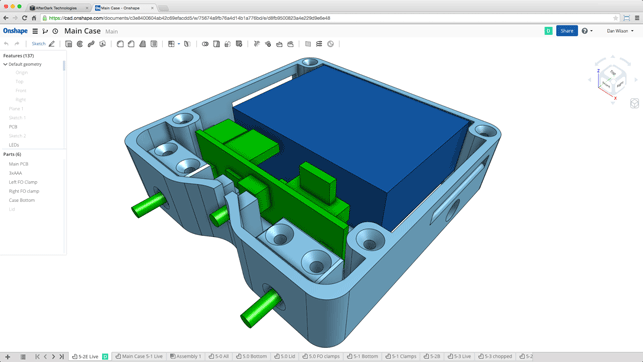

Alongside the 3D modelling tools, and due to its cloud-based nature, Onshape has data management and collaboration built in.

All of the data created and uploaded is stored centrally. It will track versions, but those versions have to be created manually, and it supports branching and merging. This allows the user to split a design path to explore options, then bring together those results into a single track again.

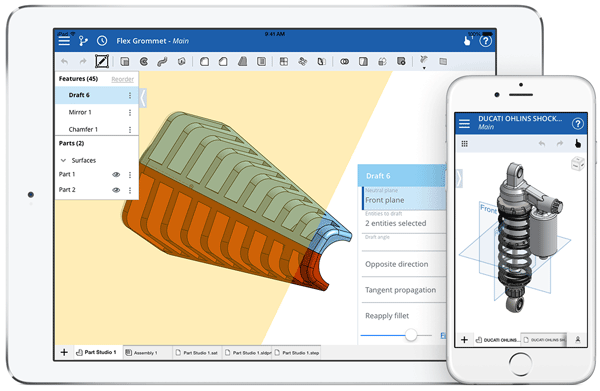

Onshape: in browser. There’s also iPad and iPhone native apps with Android coming

Of course, collaboration is easy. After all, one of the key benefits of storing data centrally is that it’s easier to share. With Onshape’s browser-based technology, the other party also has access to those tools as well (remember that bit; it’s key).

Catch up with the man himself

Onshape’s chairman, Jon Hirschtick

To discover the background to Onshape and explore its plans, we got on the phone to the man himself — Jon Hirschtick.

Hirschtick is a legend in CAD circles. SolidWorks was founded in December 1993 by this Massachusetts Institute of Technology (MIT) graduate who used $1 million he had made while a member of the MIT Blackjack Team to set up the company (how many other CAD company CEOs do you know who get to go to a movie premier with Kevin Spacey?).

Working out of a room above his garage, Hirschtick recruited a team of engineers to build 3D CAD software that was easy-to-use, affordable, and available on the Windows desktop.

Its first product – SolidWorks 95 – was released in 1995 and in 1997 French software company Dassault Systèmes acquired it for $310 million in stock.

We kicked off our interview with Hirschtick by talking about the business model for Onshape. In an industry that’s used to heavy upfront investments and ongoing maintenance, Onshape is doing things differently by making its software free to all.

Al Dean: Let’s talk a little about the ‘freemium’ model. Users get five private models — they can have more, but they need to be public. If they want more than that it’s a subscription, at $100 per month per user. This represents a shift in how mainstream modelling tools are licensed. What are your thoughts on this being critical to both long term and new users?

Jon Hirschtick: We made Onshape’s pricing model different, and we think it’s better for everyone. We tried to keep it simple, to deliver great value, and to carefully consider a bunch of common user situations.

Firstly, there’s professional CAD users and then there’s light-duty pro users (viewers, management, customers etc.).

There are also professionals who are evaluating Onshape. An important aspect here is collaboration — users can now share their model with a customer or vendor, without the other person needing to buy/install/copy/translate anything. Then there are students and makers.

Onshape’s Pro Plan is tremendous value for people who work on lots of private CAD data and the Free Plan is an awesome choice for those who can work on a small amount of private CAD data, or an unlimited amount of public CAD data.

Traditional CAD has been offered in some “free” forms, but usually free CAD means limited in time, limited in function, or it’s only for certain groups of users (prove you are a student or whatever), or it’s watermarked, etc.

OnShape’s Free Plan is different: totally free, full CAD and data management functions, for everyone, no time limit — just a limit on private data you can access at one time. Simple.

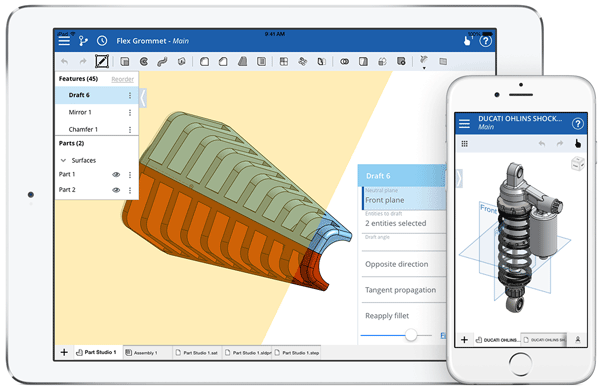

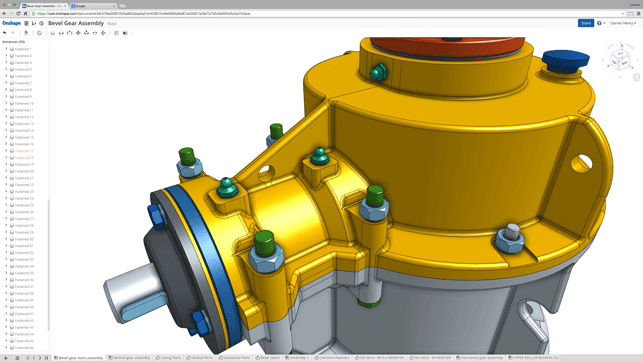

Onshape is a multi-body, Parasolid-based modelling system. And it’s slick

AD: When SolidWorks launched, it was a very different market. Users are more connected now than they were back in 1996/1997. Today there are somewhere in the region of a million users (in the professional space) of 3D CAD. How do you think that changes what you’re doing?

JH: It is a different market today, and Onshape is built with this in mind. Every engineer coming out of university knows 3D CAD and knows sketch/extrude/fillet/shell. So we know that these million+ users will find Onshape familiar. Users are indeed a lot more connected through the use of tablets, phones, Macs, etc.

Most users are also in multi-CAD situations, so we’ve built some cool new features into Onshape for working with multi-CAD data. For example, you can store native CAD files on tabs in Onshape documents. They get versioned and shared along with the rest of the Onshape document.

AD: If potential users are experienced in not only the tools they use currently, but also what else is out there, how do you differentiate yourselves — particularly as you’re launching with a set of tools that are pretty basic?

JH: No CAD modeller is ever done, but our early users are happy with our toolset (especially since we are just in Beta test) but of course they want more so they’re happy that we are improving Onshape regularly every few weeks.

It also makes them happy that they automatically get our latest versions without downloading, installing, or upgrading anything. And they are really happy knowing that every Onshape user in the world is always on the same version of Onshape — the latest one.

Onshape splits out part (in a

multi-body method) modelling and assembly modelling into ‘studios’

AD: Following this up, it’s also interesting that when SolidWorks launched, it took advantage of a platform shift combined with a dramatic lowering of cost of ownership (both for software and the required hardware). While there’s an easier engagement and investment level with subscription based models (such as Onshape has), the cost isn’t that dramatically cheaper once you start to stack it up over a couple of years.

JH: The cost of Onshape is dramatically cheaper than traditional CAD. First of course: no $5,000+ licence fee. But it’s not just that.

We also save users all sorts of other costs: hardware (as a full-cloud system Onshape runs well on just about any computer), add-on PDM and collaboration software (built-in to Onshape at the core), licence servers (good riddance!), PDM servers (again none needed), file servers (nope — we take care of that), backups (we do that too), not to mention all the costly staff time for setting up and maintaining all of this stuff. So absolutely Onshape is dramatically lowering CAD costs.

AD: We’re in the midst of the maker renaissance and there’s a demand for more accessible 3D CAD tools. While you’re shifting the economic accessibility, what about usability? OnShape has some nice modelling tools but there’s not dramatic shift in ease of use. Do you think 3D geometry modelling will always be an inherently complex exercise?

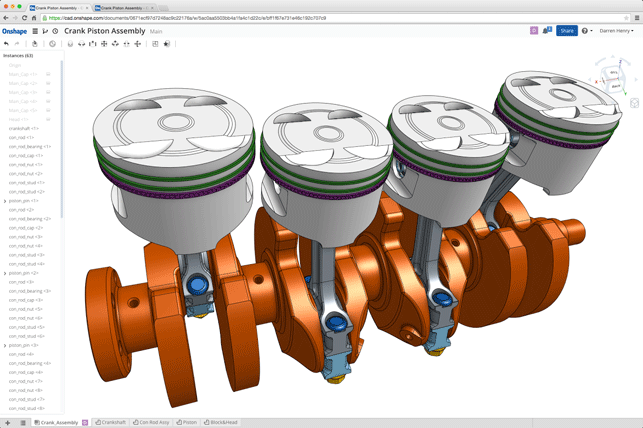

JH: We made some important improvements to traditional modelling tools while still keeping the feel of Onshape familiar to traditional CAD users. Onshape Part Studios lets users easily model multiple parts in a single part feature list. Individual features can be applied to multiple parts. The parts can be inserted and moved independently from one another in assemblies. Users love this. Many of our users are making very sophisticated multi-part studios.

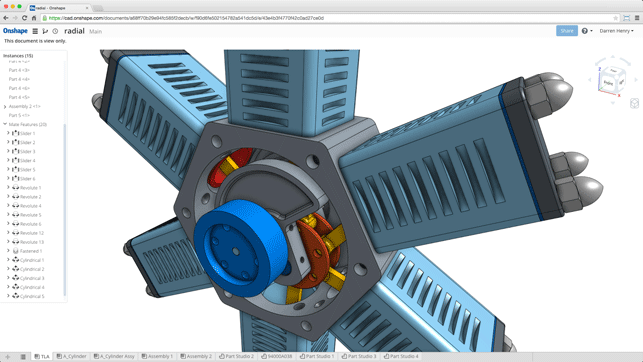

Onshape also uses “high-level” assembly mates that lets pairs of parts be mated using just one high-level mate, versus say three low-level mates in traditional CAD. And we created compound tabbed documents, which lets users effortlessly combine part and assembly modelling. It’s easy to do both as you wish, and we’ve eliminated the headaches of managing links between files on disk. All tabs in an Onshape document are 100% always at the same version.

But, of course, the number one priority is ensuring that professional users can fully model their professional product designs. Nobody has figured out how to make that level of modelling totally 100% easy. Not sure anyone ever will but we will keep trying.

AD: Cloud & API (application programming interface). Is this something that’s on your roadmap? How do you see the third party application developers working with OnShape and its different infrastructure, which might be outside of their immediate experience in terms of development?

JH: Yes we have an Onshape API and partner program and we are working now with third-party partners to develop applications. For standard desktop applications Onshape’s API supports live linking to Onshape in the cloud. That’s a great way to start an integrated partnership with us.

For cloud applications even if a partner has zero cloud experience Onshape is a cloud platform that, with our help, enables our partners to build their own cloud applications that connect to Onshape.

Also, it’s not just Onshape’s API that’s better for partners, it’s our ability to distribute our partner’s applications. As a full-cloud system we can make our partner’s cloud applications instantly available to every Onshape user. That’s never been possible before, and will be very good for both partners and, more importantly, end users.

AD: Let’s talk a little about the cloud-connectivity. There’s probably an assumption that a high-speed web connection is essential. But what’s more important — the speed or the reliability?

JH: Both speed and reliability are important. Onshape was designed from the ground up to run efficiently on standard cable, fibre, and even mobile 4G internet connections.

Internet connection speed is the fastest-improving computer technology these days.

In most countries average internet speed has increased 50% in the last 12 months. Internet speed and reliability is the first computing improvement in history that users get without doing anything — no buying new hardware, no installing new software. It simply keeps getting better.

A linear history tree (to the left), operation to the top of the UI and a big ol’ modelling window

AD: While in the technology hubs that cloud-based tools are often developed, both are available, but there’s a lot of parts of the world where they’re not. You’re not launching with an offline mode. Do you think that’s wise?

JH: We very consciously decided to laser-focus on a full-cloud, online system. As a result we’ve made online truly awesome. People who don’t have good internet service should stick with traditional desktop CAD until they do have good internet service.

Also Onshape today has higher availability than any desktop CAD system. In many parts of the world internet service is more reliable than electricity. All desktop CAD users I know have all sorts of unplanned outages — disk crashes, power outages, operating system glitches, service packs, system re-installs etc. With Onshape these problems go away. If your computer breaks just go to another computer and in seconds pick up where you left off.

Context is everything

Whilst discussing Onshape with Hirschtick, it’s difficult not to draw parallels with the team’s previous success. Launched in 1995, SolidWorks was really up and running by 1997, and at that time the dominant, hot ticket software was Pro/Engineer from PTC.

When it launched in 1987, Pro/E brought a different approach. Parametric modelling changed how things were done, changed how intelligence could be built into a 3D product model’s geometry. It also broke up the recipe that described the construction of that model into a series of features.

Now consider what SolidWorks offered. SolidWorks, at a technical level, did very little that was new or novel. Its approach to features + history + parametric was a clone of Pro/E.

The 80/20 rule applied: 80% of the functionality at 20% of the price.

What SolidWorks did, however, was to dramatically lower the cost. Pro/E at this time required some serious hardware and the software was similarly costly. There wouldn’t have been much change out of £25,000 to £30,000 per seat.

SolidWorks was delivered on the Windows platform, with lower cost hardware and cut the software cost by two thirds minimum.

It also had a sales channel that was like no other. In many cases, built up by veterans of imploding other vendors or resellers of their systems, SolidWorks attracted a different bunch. Yes, eager and hungry for success, but without some of the peculiarities of the old guard.

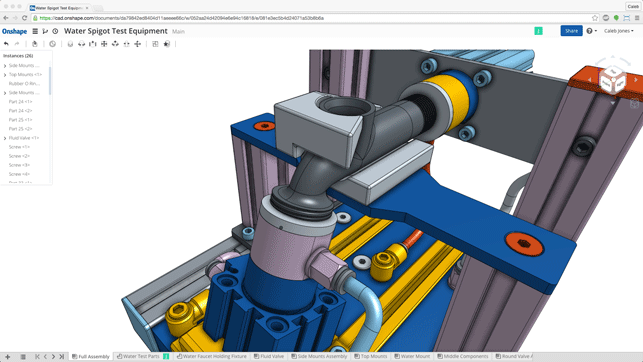

The assembly Studio gives you access to ‘joints’ based constraints definition

In essence, SolidWorks was a cheaper alternative to Pro/E sold by nice people.

Onshape looks to be attempting something very similar, using the cloud (the equivalent of the move from UNIX boxes to Windows) as the platform shift. By doing that, it’s removing the need for expensive computation as the tool work as well on a iPad as it will on a standard-ish laptop or workstation.

There is also the consideration that the environment in which Onshape is trying to do this is dramatically different. In 1997, when SolidWorks started to ramp up, PTC was shipping around 7,500 seats per quarter with a total user base of around 100,000 by the end of the year. After ten years, the company had sold, on average, 10,000 seats a year.

Now consider today’s environment. SolidWorks has, at the best estimates, over half a million commercial customers. Autodesk Inventor has similar. Then there’s Solid Edge, PTC Creo, Siemens NX and all the other 3D design and engineering systems out there.

But when SolidWorks took off, it did so in an environment where the vast majority of users had never seen, never mind used, a parametric 3D modelling system such as Pro/E. AutoCAD, ME10 and the drawing board reigned supreme.

Although they realised that AutoCAD or their drawing boards weren’t going to cut it in the future, they couldn’t afford Pro/E. But then along came SolidWorks who could get away with not matching Pro/E in terms of functionality because it was far cheaper and also simply because very few of its potential customers had even seen such prohibitively expensive technology before (remember, the internet was by no means widespread), never mind actually used it. So, no wonder SolidWorks took off and grew massively.

Collaboration is key. Product

models are version and revision controlled and branching is supported

Conclusion

The end result of the last ten to twenty years is that, today, there are literally millions of seats of highly advanced, highly capable 3D design software out there.

Today’s designers and engineers have decades of collective experience with these tools. They’re also highly connected.

In 1997, the only way to see a system like Onshape was to go to a trade show, send off for a CD or book a demo. That clearly isn’t the case today. With the tap of a few keys, you can sit and learn everything you need to about a system in a matter of minutes.

Now, bear in mind how shareable Onshape is. With the beta in place, anyone that signs up for it (and you get five free active projects to work on before you need to start paying as well as 5GB of storage) can immediately share it with someone else. Someone on their team, someone that works for a customer, a supplier, a client, a friend.

As soon as they accept that share, they’re in the tool. It runs on lower cost hardware and is usable over a 4G phone connection. No download, no high-end graphics hardware, no licensing or trials. They’re not scrabbling around for a viewer or to import the data into their own 3D design tools (if they have them).

All of Onshape’s tools are right there, to play with. That, my friends, is incredibly powerful. I think the term these days is ‘potentially viral’.

At the moment, Onshape’s modelling capability is limited, but still there are products on the market now that have been designed, tested, iterated and put into production using OnShape (I’ve visited a few of these customers already). The modelling and other supporting tools (drawings etc.) will come in time, all built on this new platform.

The 3D CAD world is still an important one and other than Autodesk and its Fusion initiative, there’s been very little new or exciting for a while. And we all like something new and exciting.

Ultimately, however, there’s work to be done and the success of a company and its products in this space comes down to folks adopting those tools and cracking on.

onshape.com

In the May issue we’ll be taking an in-depth look at Onshape and what you can accomplish with the beta test.

In the meantime, if you want to sign up and see what all the fuss is about, Onshape is accepting beta test applications on its website.

Jon Hirschtick discusses Onshape: 3D design and collaboration in the cloud

Default