Digitisation presents challenges as well as opportunities: On the one hand we’re surrounded by more data than ever before, yet on the other, we have more efficient tools to manage the onslaught.

Nowhere is that more apparent than in additive manufacturing. Engineers, operators, managers and others are constantly searching for designs to make sure they’re printing the right one, finding previous templates or parameters, checking IP, comparing costs, and much more.

In the process of searching for similar designs, while we have traditional search methods like text based and keyword based, they do fall short at times.

Geometric Search Engines (GSEs) can significantly improve speed and efficiency of the digital thread in additive manufacturing to help solve these challenges.

The tools enable the search for 3D designs by geometry, not just keywords. Users can create their own databases of all designs previously quoted or designed, for example, or they can use existing ones such as ‘all known successfully printed designs’ to identify viable additive manufacturing candidate parts, or to make sure they’re not contravening the Intellectual Property (IP) of others.

For organisations, IP protection is of primary importance – it makes their designs valuable – and a fear of IP theft often stops them from using the vast ocean of third-party services in the cloud.

Using design quoting as an example, getting those quotes for a design can help predict the manufacturing cost, thereby helping find potential suppliers. However, how do you use third-party services without giving away your IP?

Authentise recently came up with a plan to use a GSE as a powerful underlying tool, and built a wrapper Application Programming Interface (API) around it.

The API smartly takes care of passing just the designs to the search engine, separating the storing and the searching process for all the designs in your organisation.

Companies with IP sensitive designs, seeking quotes from several cloud services, can choose to not give away their models by giving the system a set of whitelisted designs.

There are two phases involved in this process.

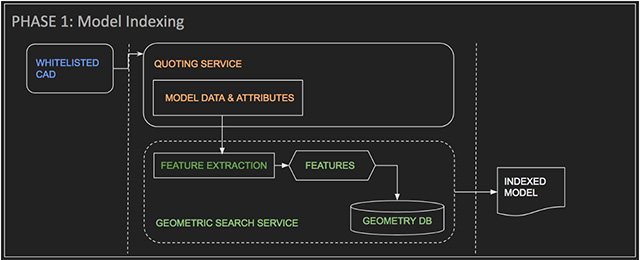

First is the indexing phase. In this, the whitelisted set of models are passed via the API. The API takes care of inserting the designs into the GSE for indexing.

The indexing is like any other indexing technique for data analysis. With an efficient feature extraction algorithm, the search engine, stores the features, thumbnails and user provided key attributes of the designs. A design is essentially broken down into these set of characteristics and saved in the search engine.

The platform provides a way for users to index designs simultaneously from different part of the organisation, in fact it’s easy for users to add, delete or update an indexed design.

The corpus of designs is indexed and ready. Now is the time to search for similar models for a sensitive design against this set of indexed data.

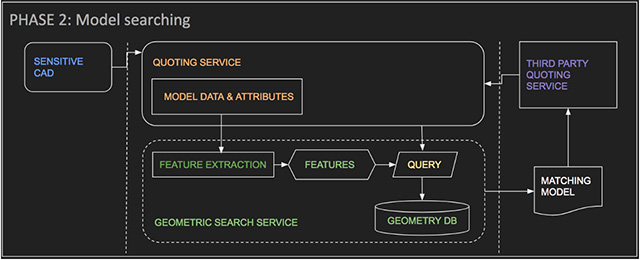

This is the search phase. The IP sensitive design is provided to the API. There are permissions on this designs to help protect it from external entities. This design is provided by the API to the geometric search engine, to be searched against the directory of stored designs.

The engine has the power to search thousands of indexed parts simultaneously. It comes back with a list of similar designs.

The search also takes in parameters like size and level of similarity to be matched, which makes it easier to target the search results.

A dataset with huge collection of iterative designs, often gives very promising search results for similarity.

Once a list of similar designs is extracted, these designs can be sent to third-party services for quotes. The quotes from different services can be compared to give a good estimation of what the cost of production for the sensitive design would be, even without distributing the design itself, and the data remains protected.

So a company can estimate material cost and manufacturing cost for a design by using very similar designs from the past, without leaking the sensitive data.

This is just one use case, with this GSE also able to be used within a company to save engineering effort by recognising duplicate designs, saving the time and effort of the design team.

In additive manufacturing there are many challenges faced by a company from design to production process, with a lot of them solely dealing with creating designs, preventing duplicate work, finding cost of production for the designs, recognising printability for a design based on past experiences.

There is a lot of potential for automating these processes by using useful tools like this search engine for identifying designs. Part of any process can be, translating from one design to another similar design.

Complicated processes involving nesting designs together for manufacturing could be assisted via analysis on how a geometric model has behaved in the past, what support structure or orientation produces best quality. This roots back to the design itself, and the data relating similar designs and their behaviour.

Having such useful information helps predicting the printability of the nested designs.

Geometric search is not new, it’s been used for decades to identify parts in PLM systems, but this is the first time it’s been liberated from these constraints and is being provided as a modular building block as part of a digital workflow.

This gives us the power to use GSEs in many different contexts to help create a more efficient and agile production system, where the real power comes from combining it with other modules.

Anusha Iyer is developer and computer vision boss at Authentise. Anusha is super excited when it comes to image processing and machine learning.

She completed her Masters in Computer science from UNC, Charlotte.

When she is not analysing images, she is surely being creative designing or decorating.

Used for decades in PLM systems, they now have a wider role, says Anusha Iyer

Default