The specialist hand-held laser tracked game controller that Holovis created with help from Amalgam

No stranger to creating unique, experiential experiences for theme parks and other entrainment -based venues, Holovis had something special up its sleeve for the International Association of Amusement Parks and Attractions (IAAPA) Expo 2015. Taking place in Orlando, it promised visitors “a highly compelling storyline with perfectly synched motion, and incredibly accurate interaction.”

Holovis did indeed deliver on this promise as its stand consisted of a ten metre inflatable dome in which up to 12 visitors could sit on a motion platform to experience Crimson Wing, an interactive 3D game designed entirely by the Holovis Media team.

As a world first, the 3D-immersive experience was rendered in real-time and projected onto the dome’s 360 degree screen. Visitors entering the MotionDome experienced the Holovis In-Mo game-engine system, featuring the Crimson Wing game, dynamic movement in the seats, and interaction using the specialist hand-held laser-tracked controllers.

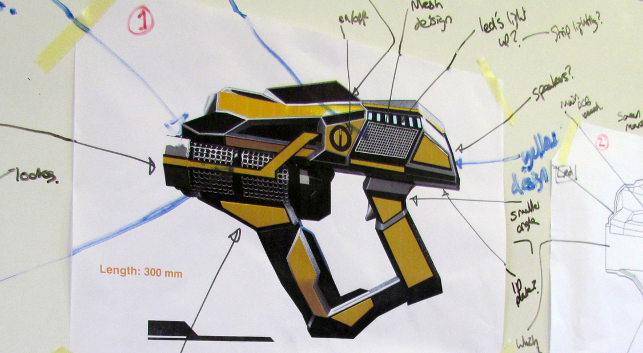

Working through the concept sketches

In the run up to the launch at IAAPA, Holovis sought out the services of Bristol-based Amalgam to develop the game’s controller shells. The brief to this modelmaking and prototyping company was to model and test the controller designs, then develop the prototype.

Tracking the design process

Holovis came to Amalgam with a basic outline shape developed as a 3D concept. The first priority was to develop the ergonomics, starting with the handle of the controller.

To test each handle design, Amalgam cut controller handles out of modelling foam, using its 3-axis CNC machine. Once the team determined the desired shape and best size, Amalgam adjusted the CAD model and applied finer exterior design details to it.

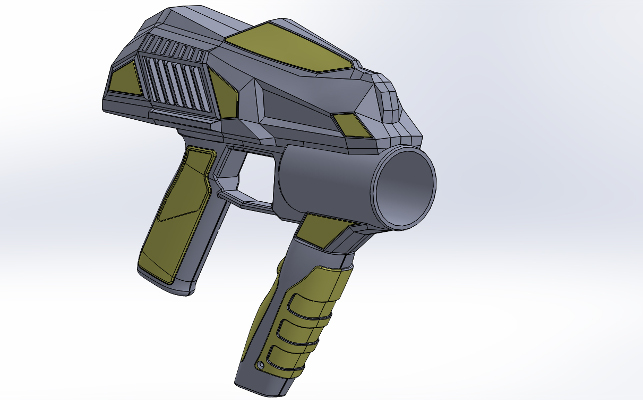

Once a desired shape and size had been decided upon, Amalgam created the final CAD file

The concept version was then shelled out, for Amalgam to apply all the required internal features and electronic support bosses. The next stage was to develop the files into a final design, which took a further four weeks of complex CAD work.

After completing the CAD files, Amalgam 3D printed a set of parts, for finishing and assembly to use as vacuum casting masters.

The next step was to produce a set of soft tools, and finally a small batch of game controller casings. Amalgam then fitted the electronics inside, to complete the batch of prototypes destined for the show in Orlando.

Andy Biller from Holovis observed, “These prototypes will form part of an important and developing thread of our business over the next 12 months. It really does feel like working in an integrated team, with Amalgam contributing their insight and experience of materials and production techniques into the overall development process.”

After completing the CAD files, Amalgam then 3D printed a set of parts for finishing and assembly

Application for other industries

Since the IAAPA show, Holovis has published its Extended Preview Video, which shows how excited the audience were inside the dome and, as such, highlights the power of virtual reality. Using its technology, Holovis continues to create highly immersive sensory experiences, which are becoming massively popular for visitor attractions, theme park rides and museums.

The final controller in use within the MotionDome that featured the Crimson Wing game

Yet the potential for use in other industries is huge: visualisation for product development teams, 3D learning and research environments, and as a powerful marketing tool. One of the dome’s key benefits is that it can be swiftly deployed, making it particularly suitable for events and product launches.

This article is part of a DEVELOP3D Special Report into Virtual Reality (VR) for design, engineering and manufacturing, which takes an in-depth look at the latest developments in software and hardware and what you need to get up and running.

Everything is for a reason How McLaren Automotive unleashes VR to create faster cars with more attention to detail

Quick guide: VR enabled applications A list of what’s out there now or coming soon

Virtual Reality challenges & future Six industry thought leader’s views on the future of VR

HTC Vive: Getting up and running Our experience of working with HTC Vive and how to avoid common mistakes

Workstations & GPUs for VR A back to basics guide to buying hardware for Virtual Reality

The future of immersive engineering Virtual Reality (VR) is the current hot topic, but Augmented Reality (AR) and Mixed Reality (MR) is on its way. We take a look at where things are heading

VRED Pro 2017 & VR The latest release adds greater support for the HTC Vive and Oculus Rift tools

Virtalis VR4CAD Offering expertise in VR at a much more affordable level

ESI Group IC.IDO 11 ESI’s IC.ID0 is one of the most advanced Digital Mock Up tools available. With its addition of Vive support, we take a look at what the system is capable of and how it can benefit engineering

Gravity Sketch Beta An interesting take on Modelling in Virtual Reality

Google Tiltbrush A system for VR creativity that’s both cheap and capable

Oculus Medium A good contender for design experimentation

Amari Magnetar V25 This stylish workstation has been specifically designed for VR. But despite its slimsline chassis, you can still cram in incredible processing power

Nvidia Quadro P2000/P4000 Nvidia is changing the landscape of professional 3D graphics with a new family of Pascal Quadro GPUs, including a single slot ‘VR Ready’ card.

To read all the articles, as they appeared in DEVELOP3D Magazine, you can download the March Edition here.

Amalgam creates game controllers for Holovis

Default